Powder is an aggregate of solid particles, and there are interaction forces between the particles. Powder as an aggregate can change its shape and volume by flowing like a liquid or being dispersed in a gas. Although individual particles are solid, they can behave differently from normal solids, liquids, and gases, so it is important to analyze and evaluate them using appropriate measurement techniques to understand the physical properties of powders.

The physical properties of powders include primary physical properties as the constituent particles and secondary physical properties as the aggregate of particles. Primary physical properties include particle size, shape, surface structure, internal structure, specific surface area, pore distribution, density, strength, and moisture content. Secondary physical properties include particle size distribution, flowability, dispersibility, cohesion, floodability, compressibility, permeability, shearability, and friction properties. In order to quantitatively evaluate these powder physical properties, we conduct multifaceted analysis using a variety of measurement methods.

Primary physical properties

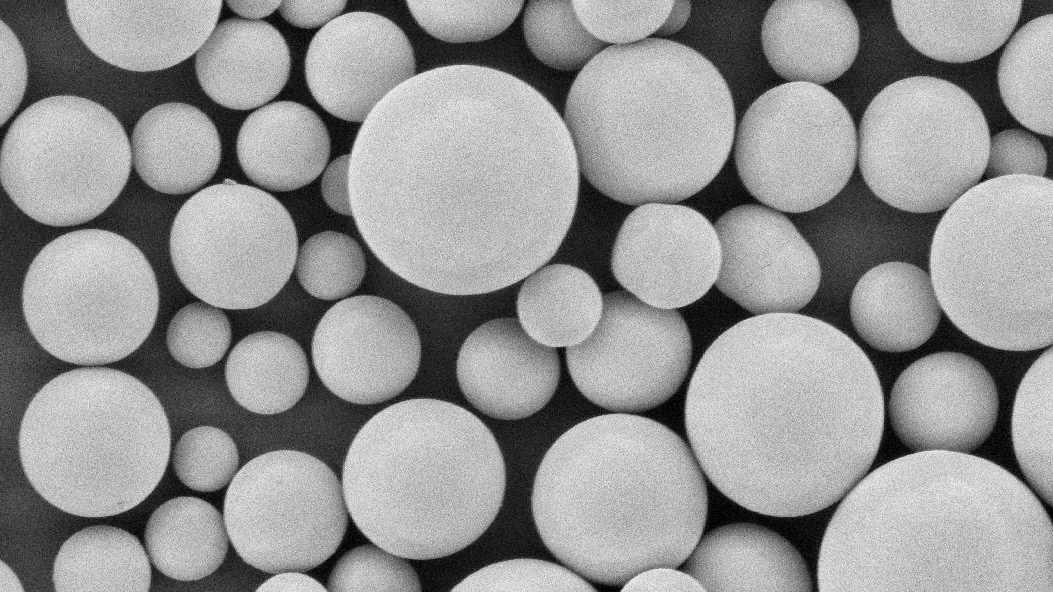

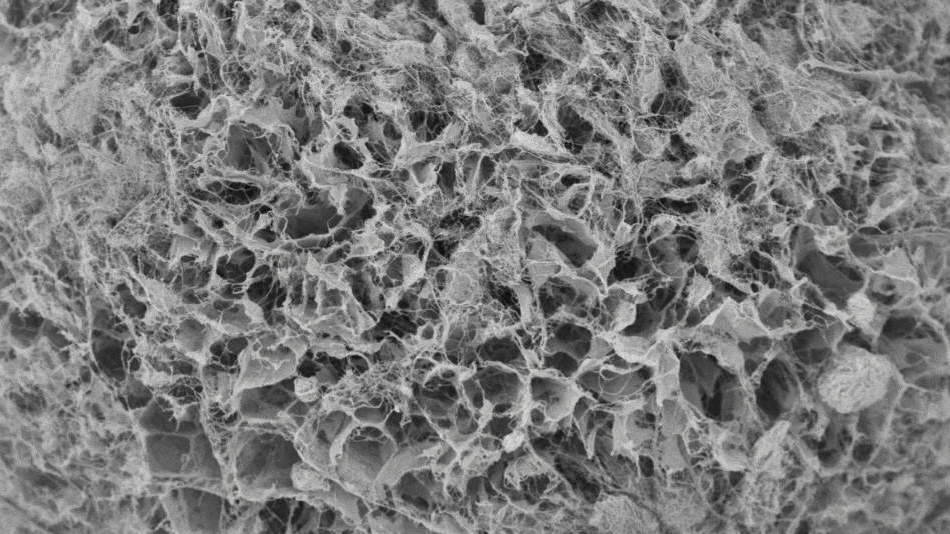

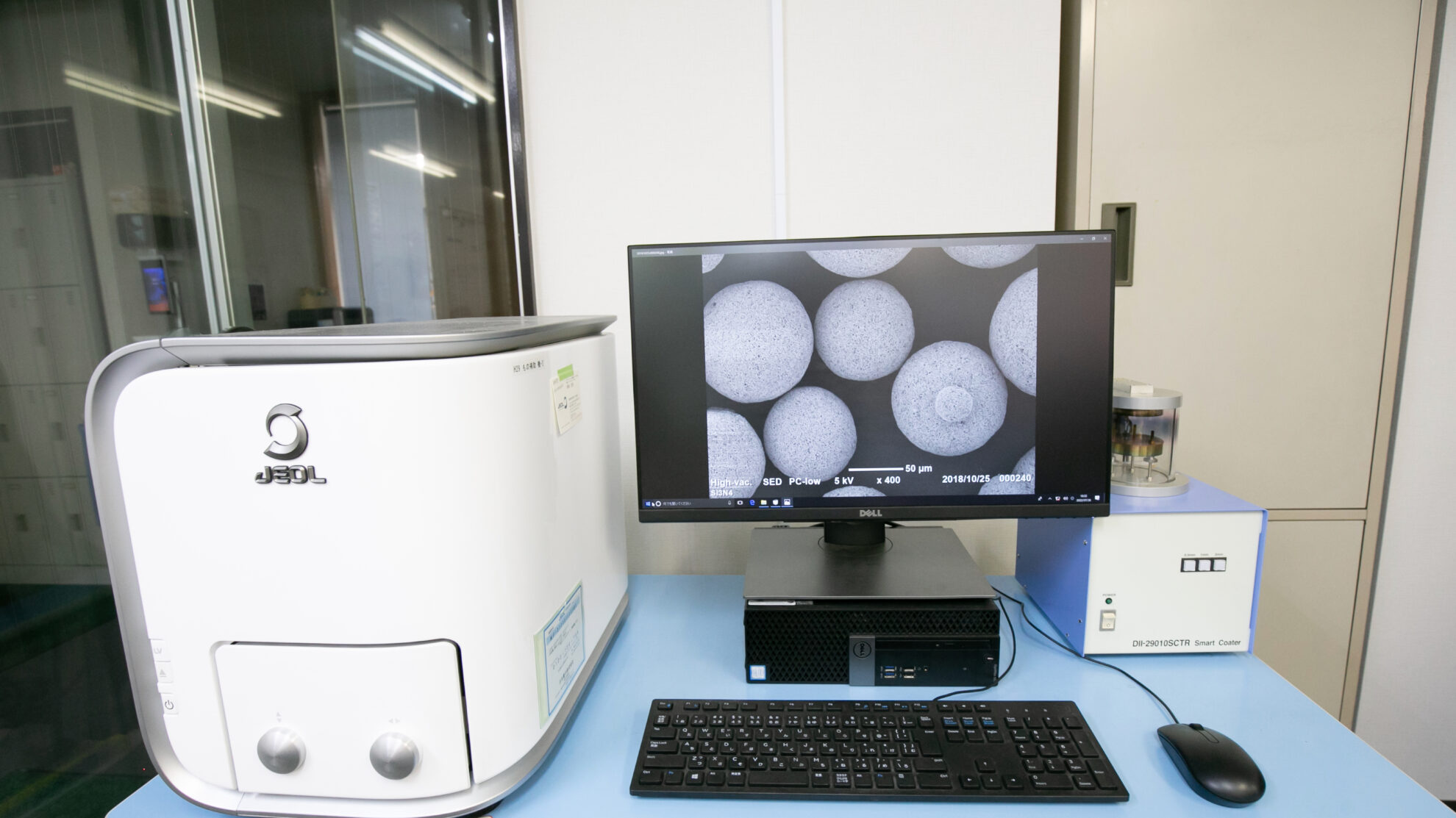

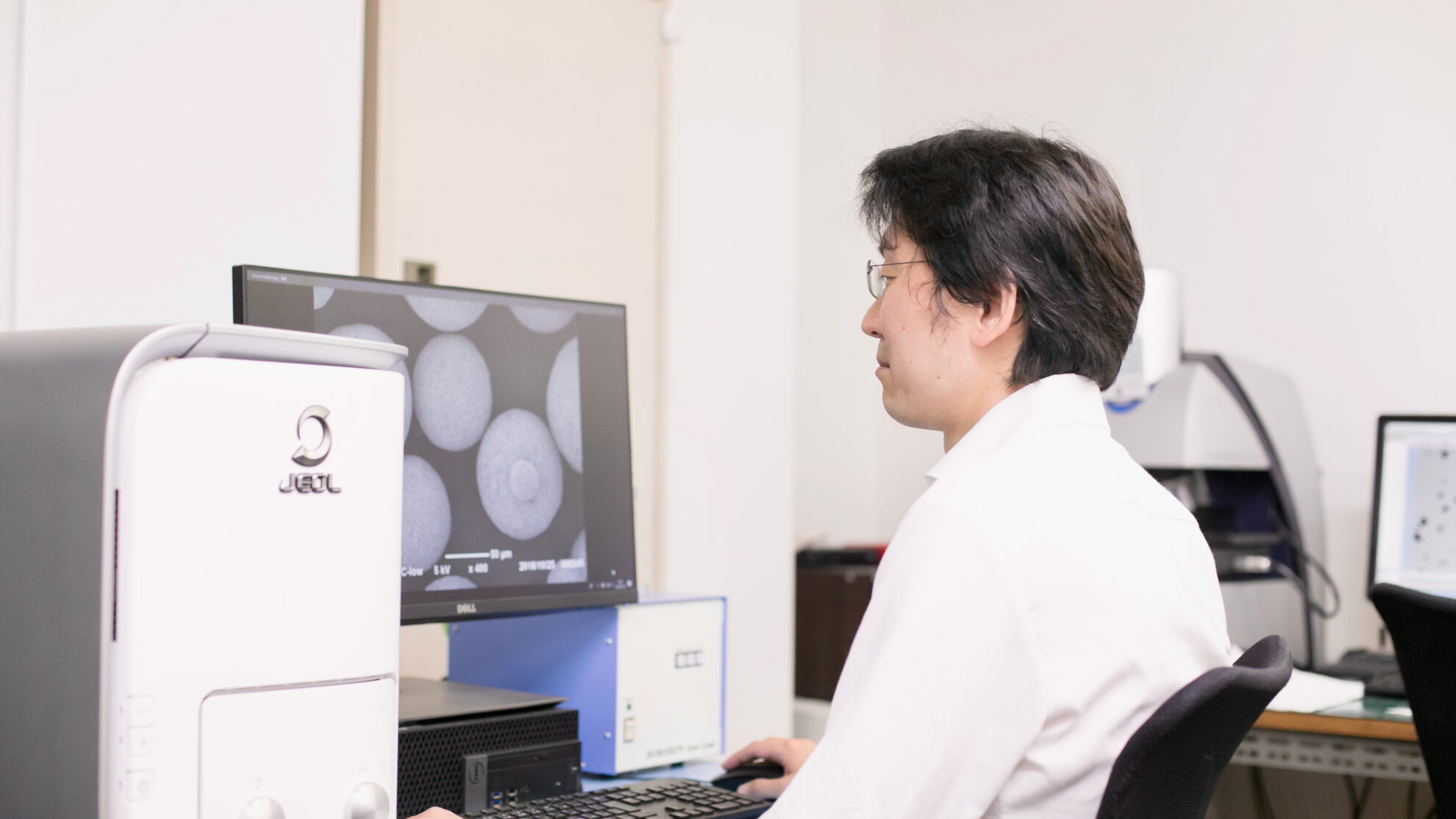

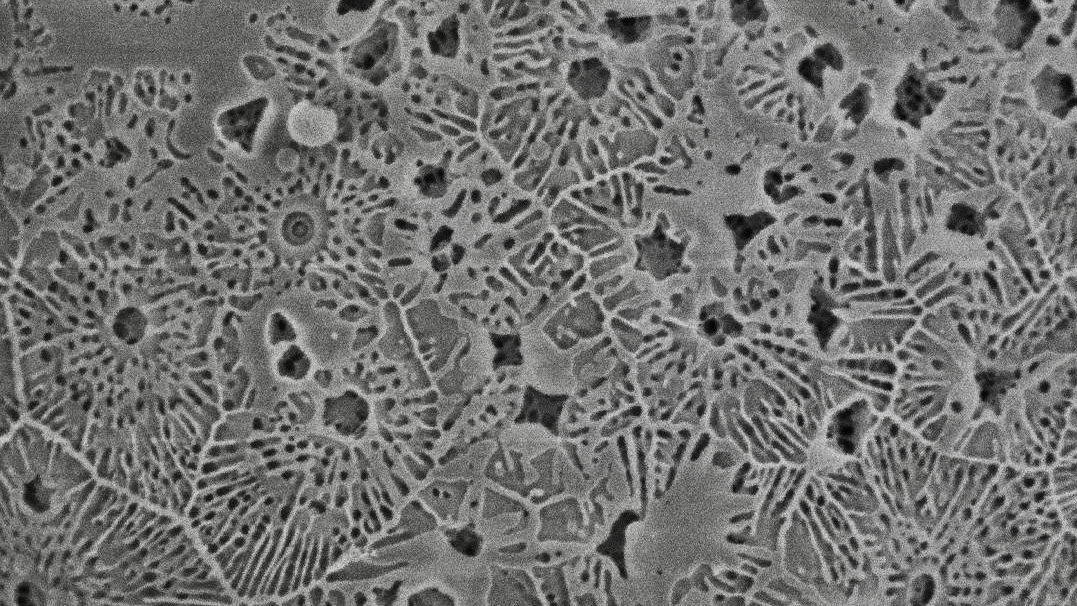

Scanning electron microscope (SEM) analysis

Measurement items: Shape, Structure, Surface, etc.

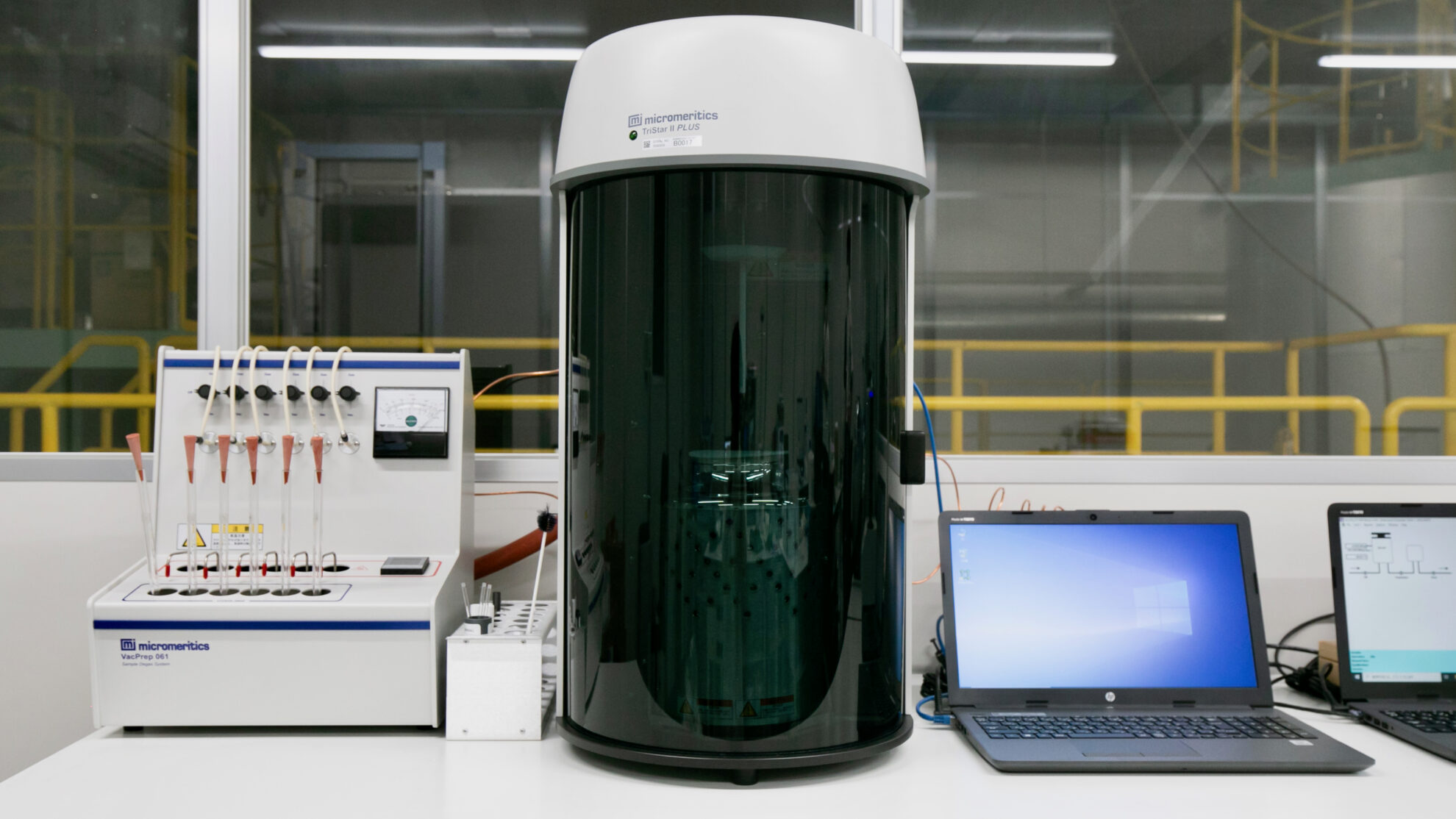

Specific surface area & pore distribution measurement

Measurement items: Specific surface area, Pore distribution

True density & particle density measurement (gas displacement method)

Measurement item: Density

Particle crushing force measurement

Measurement item: Particle crushing force (Strength)

Moisture measurement

Measurement item: Moisture content

For primary physical properties, we observe and analyze shapes, structures, and surface structures of particles by a scanning electron microscope (SEM). In addition, we evaluate the shape of individual particles captured by an imaging analyzer using various parameters such as circle equivalent diameter, area, perimeter, sphere equivalent volume, and aspect ratio by an image-based analyzer. In image analysis, it is also possible to perform brightness analysis by measuring light transmittance. Specific surface area and pore distribution are measured by a constant volume method using gas adsorption. Regarding density, we measure true density and particle density using the gas displacement method. The strength of a single particle is measured by physically crushing the particle using a particle crush force analyzer. Moisture content is measured by coulometric titration.

Secondary physical properties

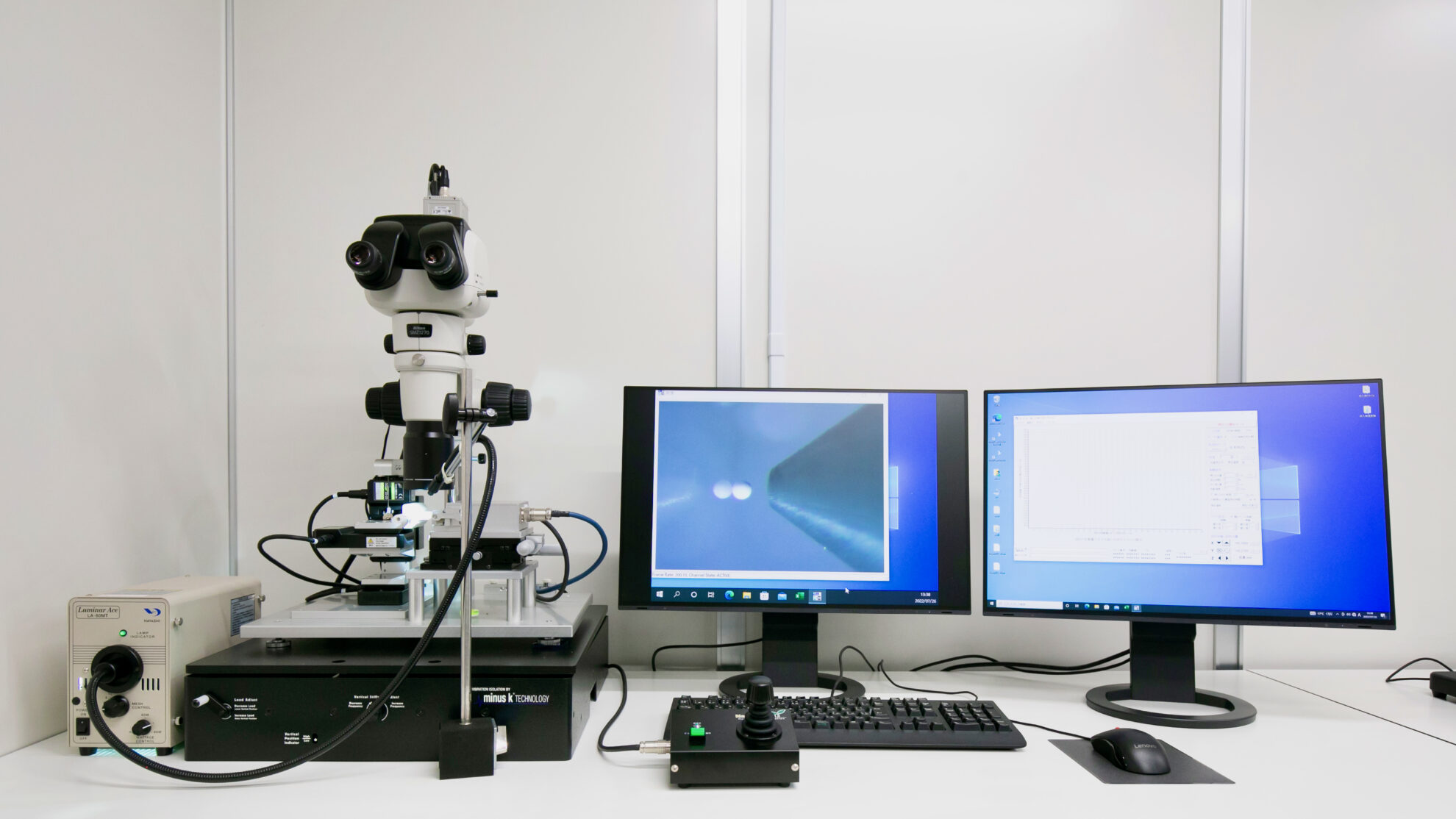

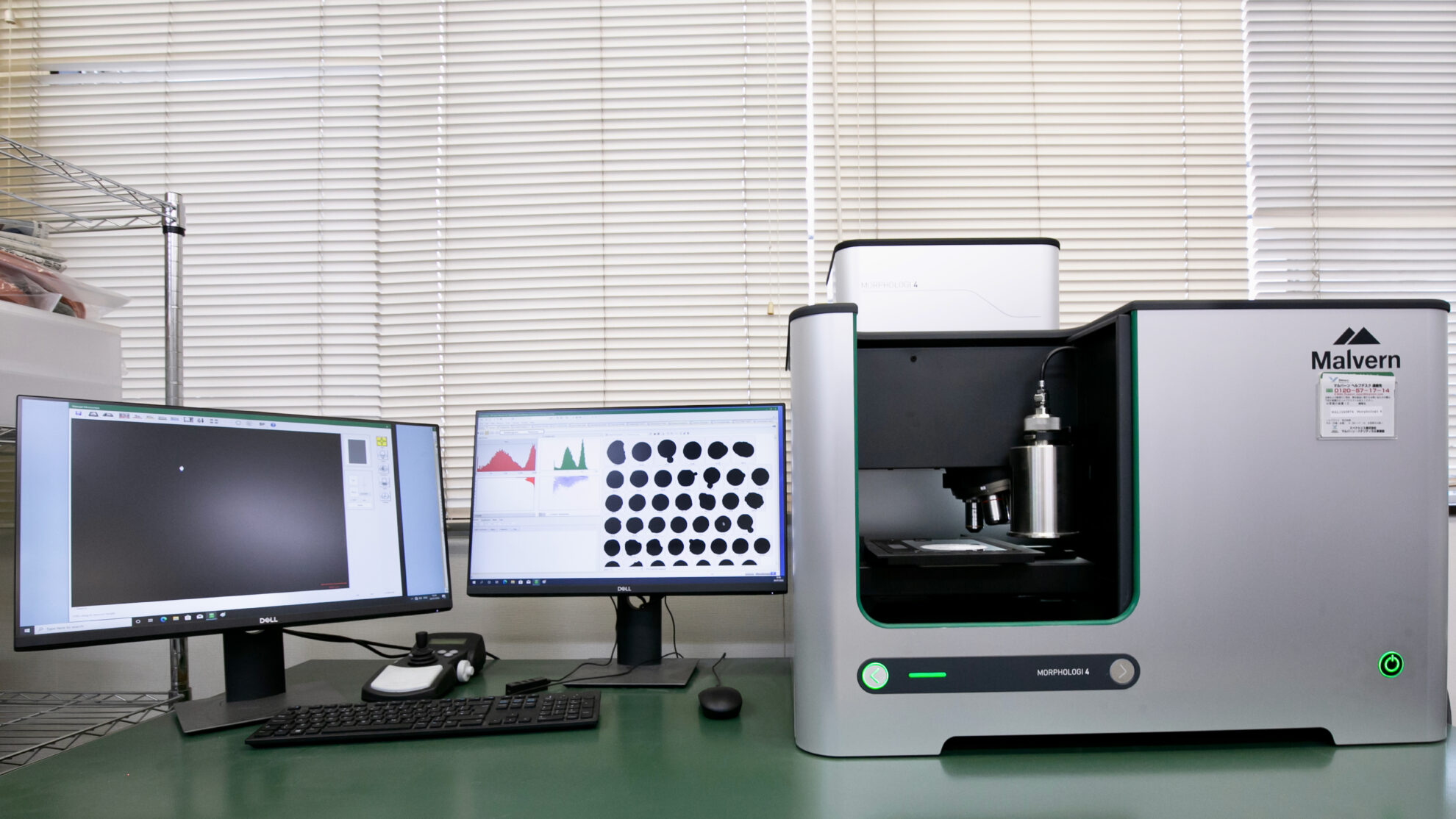

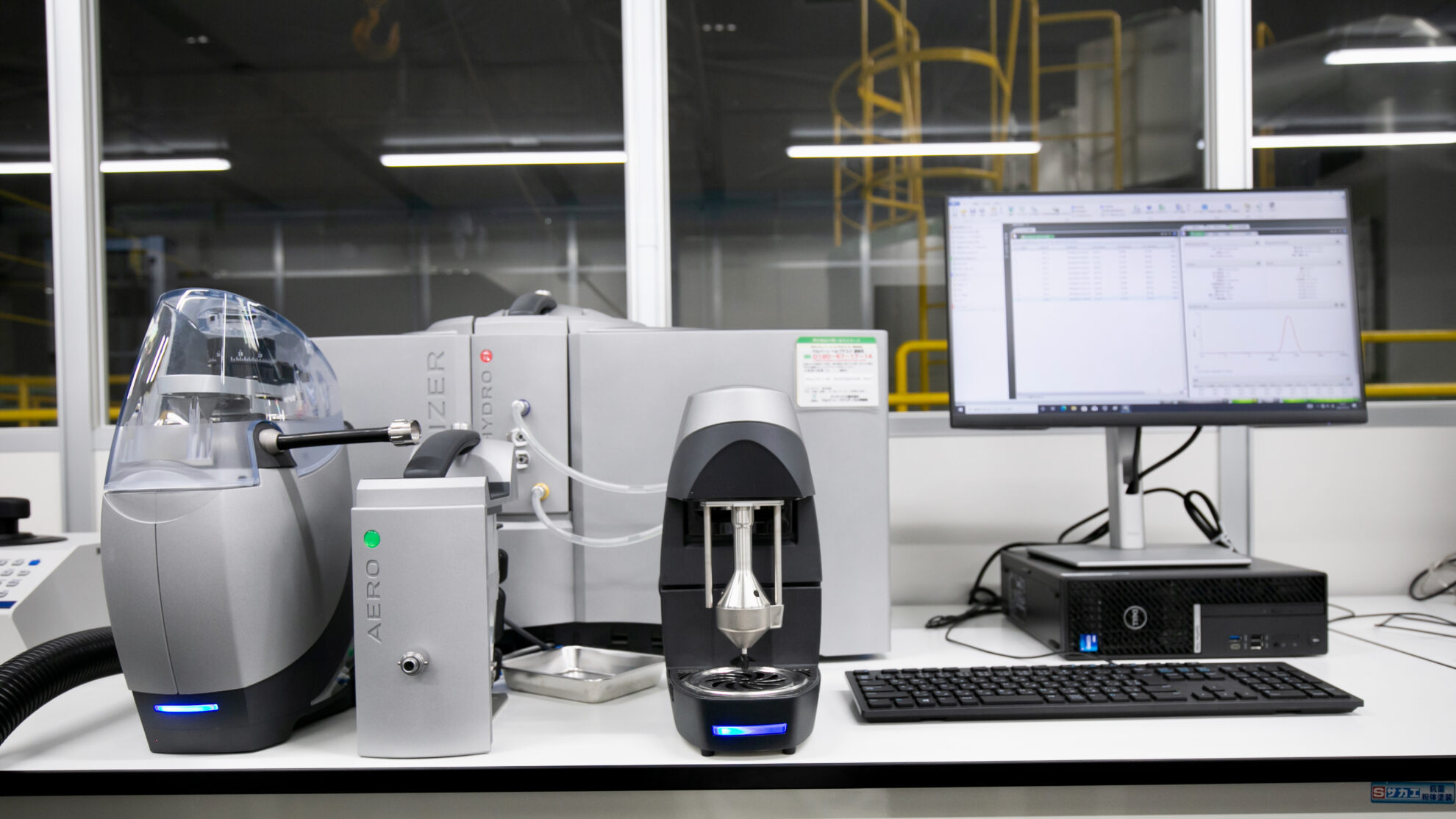

Image-based particle shape & particle size distribution (PSD) measurement

Measurement items: Particle size, Particle size distribution (PSD), Shape, Light transmittance, Number, Position

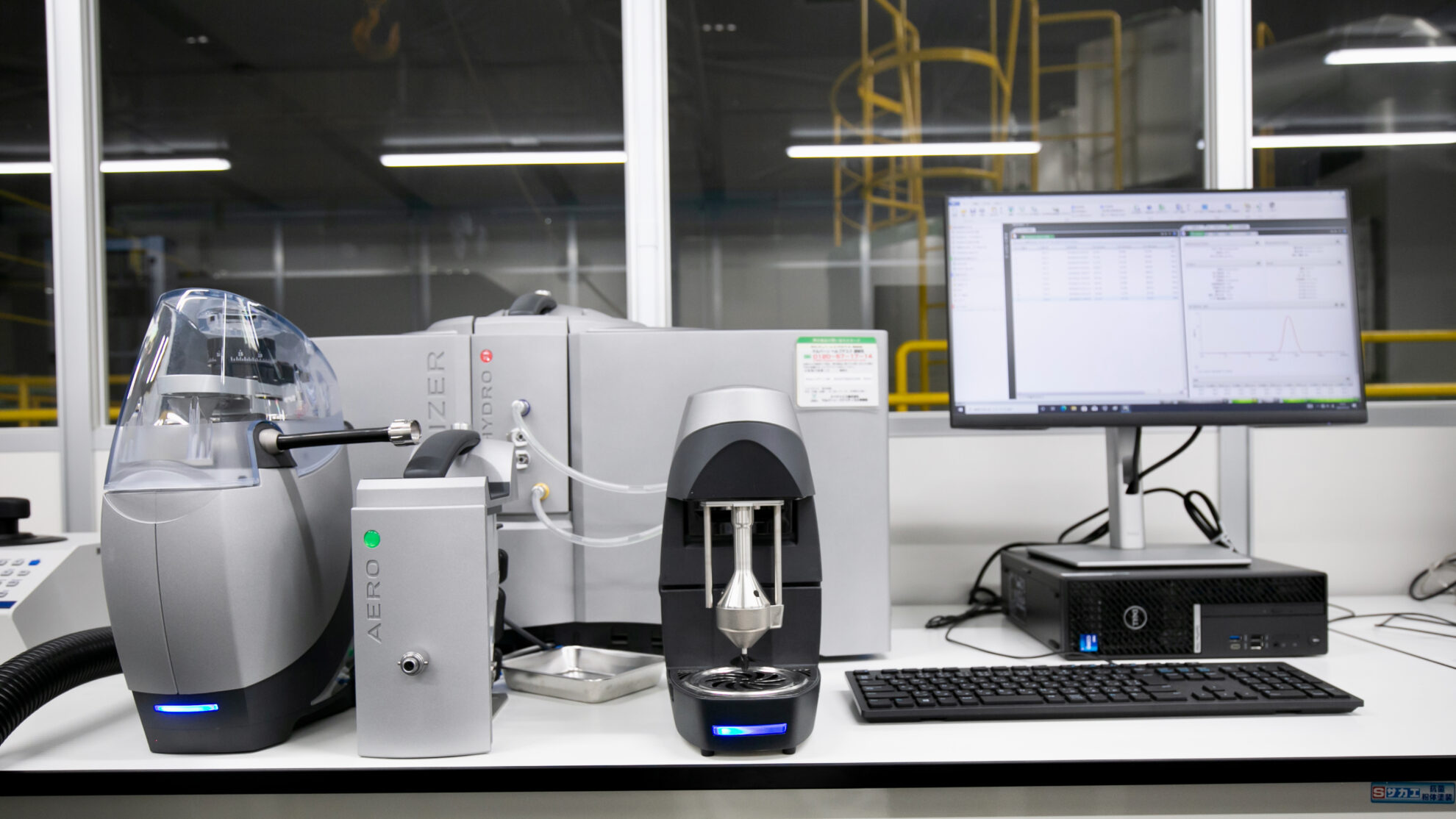

Laser diffraction particle size distribution (PSD) measurement

Measurement items: Particle size, Particle size distribution (PSD)

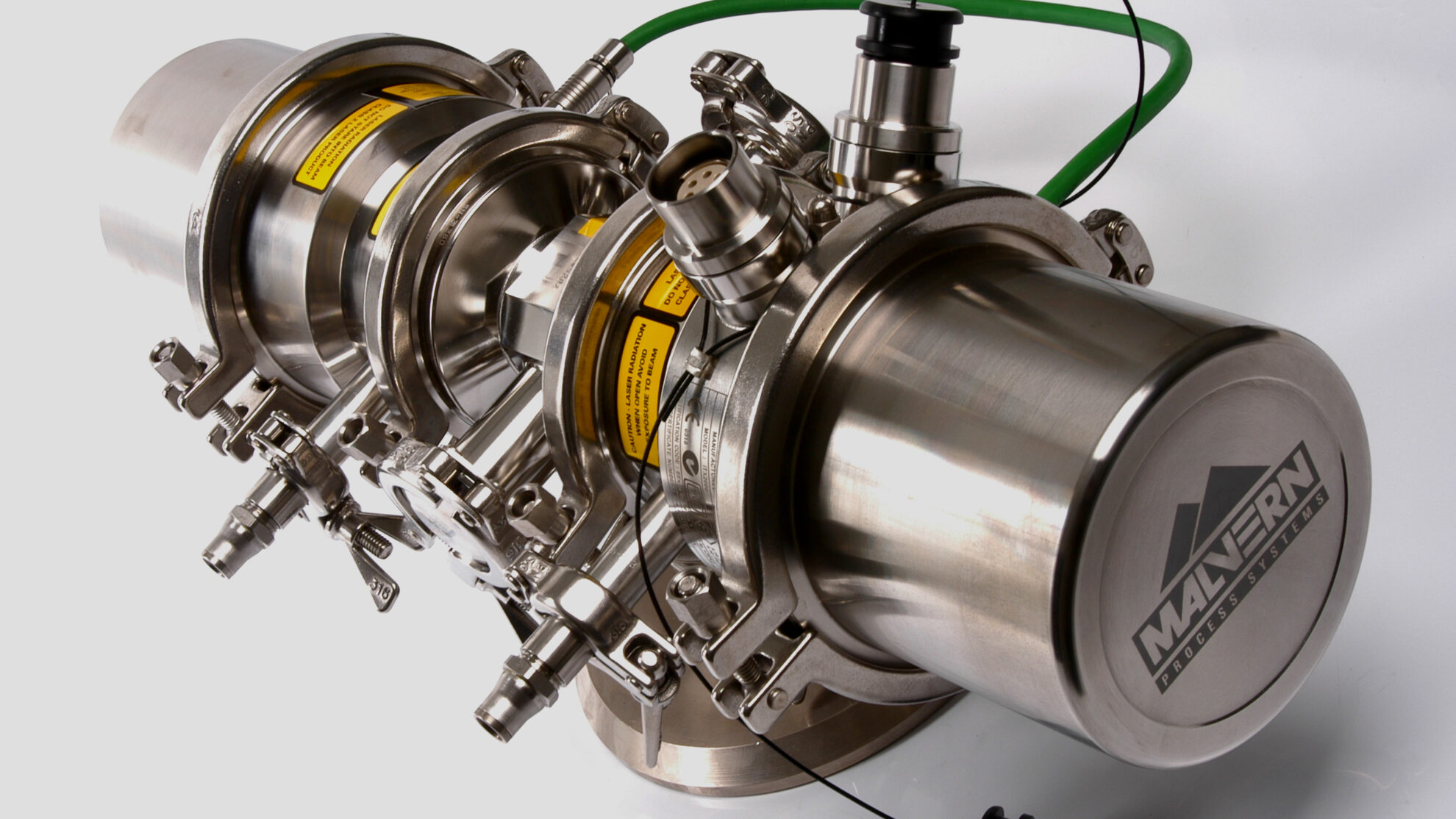

Real-time laser diffraction particle size distribution (PSD) measurement

Measurement items: Particle size, Particle size distribution (PSD) *Continuous measurement

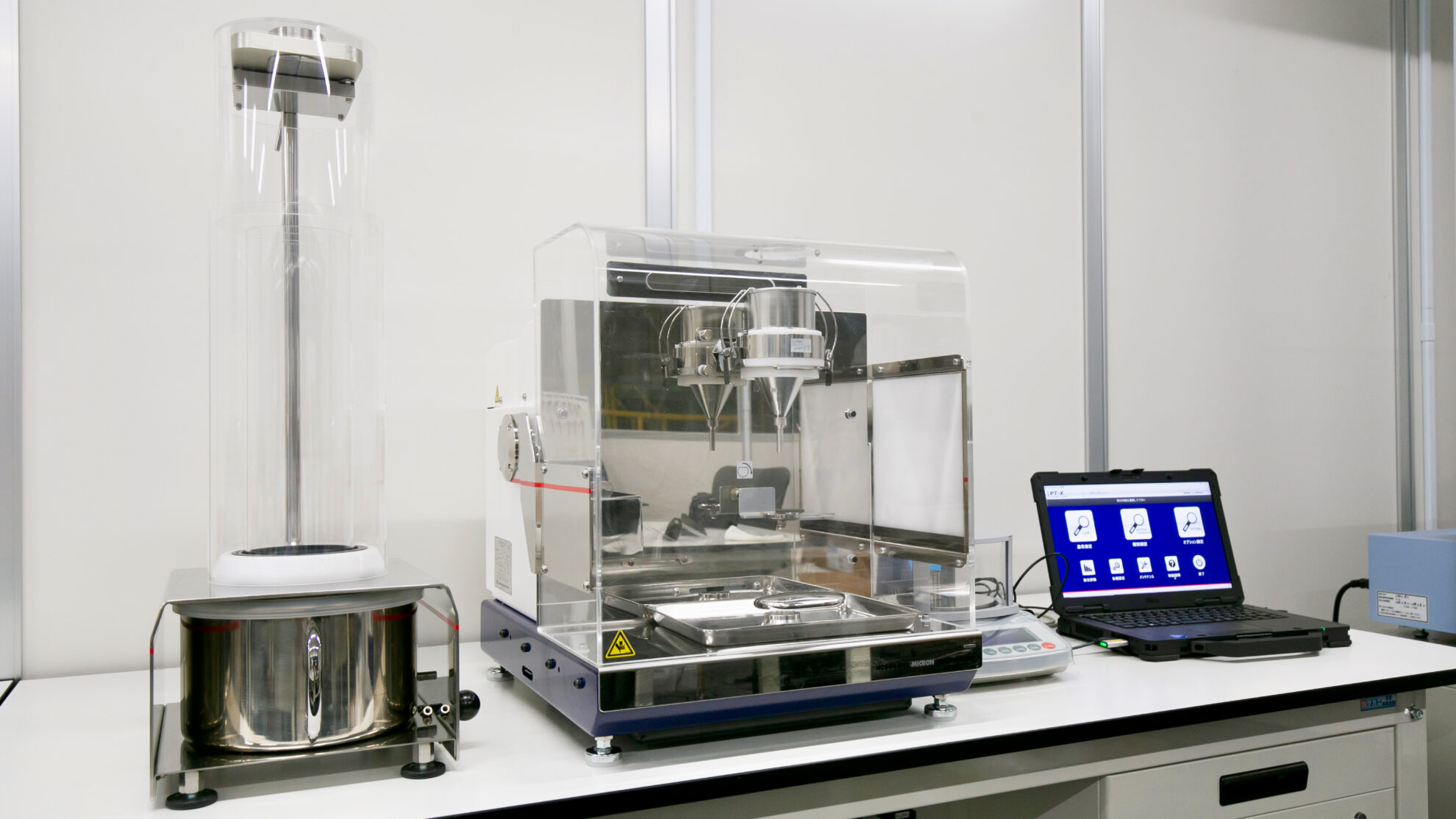

Powder characterization analysis

Measurement items: Angle of repose, Compaction, Spatula angle, Cohesion, Angle of fall, Dispersion, Angle of difference, Aerated bulk density, Packed bulk density, Uniformity

Powder flowability analysis

Measurement items: Stability, Flow rate change, Compressibility, Permeability, Shearability, Wall friction, Bulk density

For secondary physical properties, we observe and analyze the properties that particles behave as an aggregate. We use image-based particle shape analysis to evaluate particle shape and particle size distribution (PSD) using various parameters. We may also perform particle size analysis in a dynamic environment by using a real-time laser diffraction PSD analyzer. In addition, disintegration over time can also be evaluated by circulating particles and continuously measuring them using a laser diffraction PSD analyzer. Rheology analysis involves the evaluation of powder characteristics and flowability. In addition to the traditional methods of evaluating flowability, such as angle of repose and bulk density, we can perform various flowability tests under a dynamic environment. Dynamic evaluation in rheology can also analyze the disintegration properties due to friction between flowing particles, making it possible to evaluate the filling properties and handling properties of powders.

Liquid physical properties

Wet laser diffraction particle size distribution (PSD) measurement

Measurement items: Particle size, Particle size distribution (PSD)

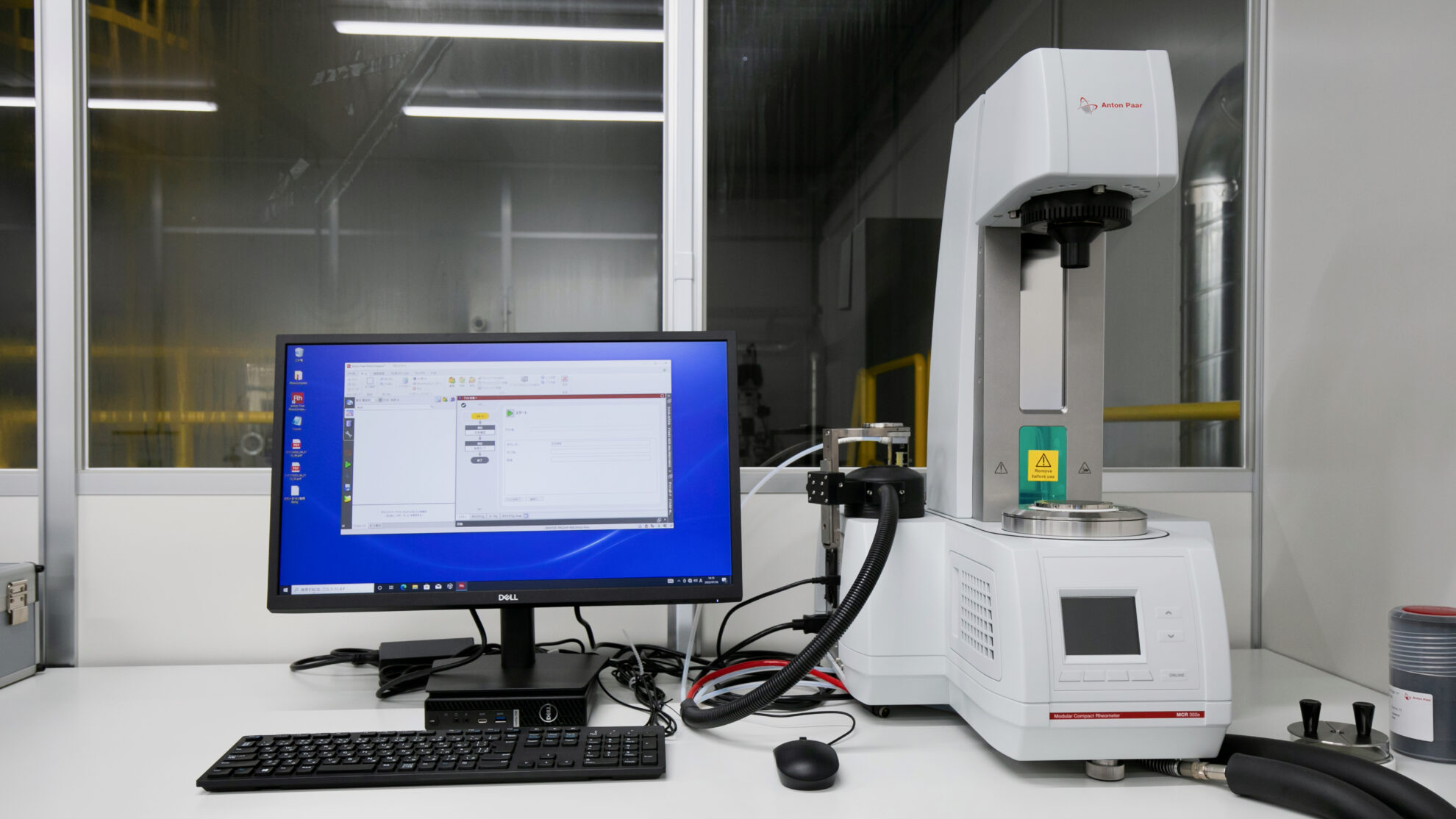

Wet viscosity measurement

Measurement item: Viscosity

Wet rheology analysis

Measurement item: Dynamic flow characteristics

The physical properties of liquid materials are evaluated for parameters that affect the latter process, powder manufacturing. In the case of slurries or suspensions, the particle size distribution (PSD) is measured using a wet laser diffraction PSD analyzer. By continuously circulating a liquid material and measuring the particle size, it is also possible to evaluate changes in cohesion, disintegration, and re-dispersibility. We also perform rheology analysis using a wet rheometer. We evaluate dynamic behavior such as viscoelasticity, shear stress, cohesion/dispersion stability, thixotropy and dilatancy properties, and yield point.

Trials, contract processing & analytical measurements

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand under the partnership with T.S.K. Engineering. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements / Contract Powder Processing).