From a sustainability perspective, industries are required to save energy, improve energy efficiency, and reduce carbon dioxide emissions. Powder production processes involve many processes that involve phase transitions such as evaporation, melting, condensation, solidification, and sublimation. Each single process uses many pieces of equipment, electric motors, and cooling and heating sources. Production processes that involve heating and cooling not only consume electricity, which is the main utility, but also fossil fuels such as gas and oil, steam supplied from boilers, and cooling sources such as chillers. Reducing consumption of these utilities and improving energy efficiency has real benefits, not only environmentally but also in reducing production costs.

Spray dryers produce a powder by spraying a liquid and drying the droplets with hot air. The heat to evaporate the moisture is high and it consumes a large amount of energy. In order to reduce the energy consumption of the spray dryer process, it is necessary to design the process appropriately with energy-saving consideration. On the other hand, from the customer’s perspective, when introducing a spray dryer process, it is necessary to determine the investment costs that are feasible from a budget standpoint. Reducing initial investment costs is extremely important for business operations, but when viewed from the perspective of the life cycle cost of the entire production process, saving energy consumption ultimately leads to profits.

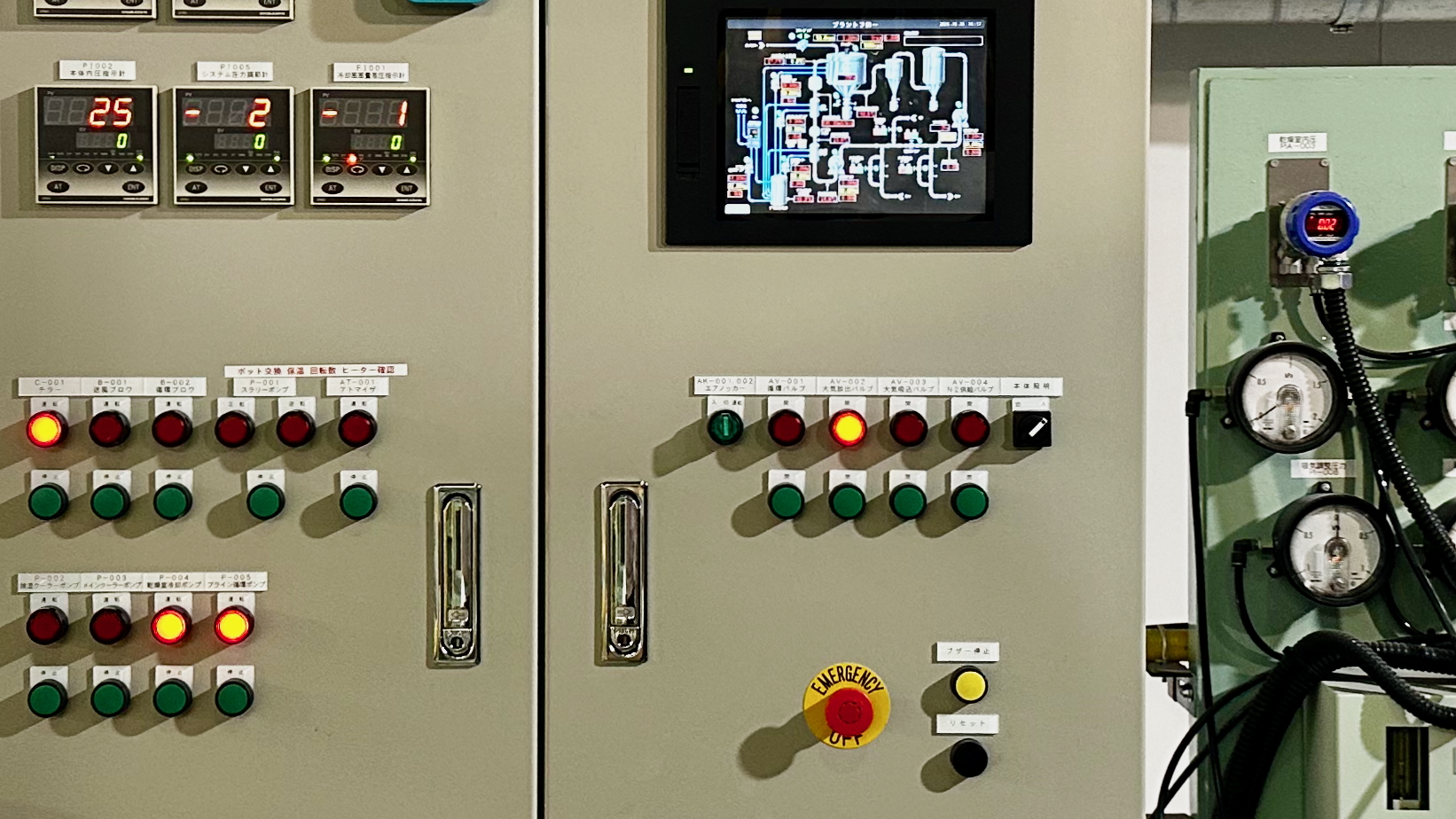

We are actively promoting energy saving technologies in our spray dryer processes. For example, in the case of a standard open cycle system, the residual heat of the exhaust gas is often exhausted and wasted. However, it is possible to introduce a heat re-circulation system that recovers and reuses the waste heat.

Additionally, when using an organic solvent, a closed cycle system using an inert gas such as nitrogen as the drying gas is selected. The solvent that evaporates during spray drying is being condensed and recovered at a condensation unit within the process. The heat of condensation required is the same as the heat of vaporization, so that the closed cycle systems consume even more energy than open cycle systems. Even in closed-cycle systems that perform evaporation and condensation, we strive to improve the energy consumption efficiency by introducing appropriately designed heat exchanging systems, using high-performance insulation materials and high-efficiency motors, and designing layouts that minimize the heat transfer distance.

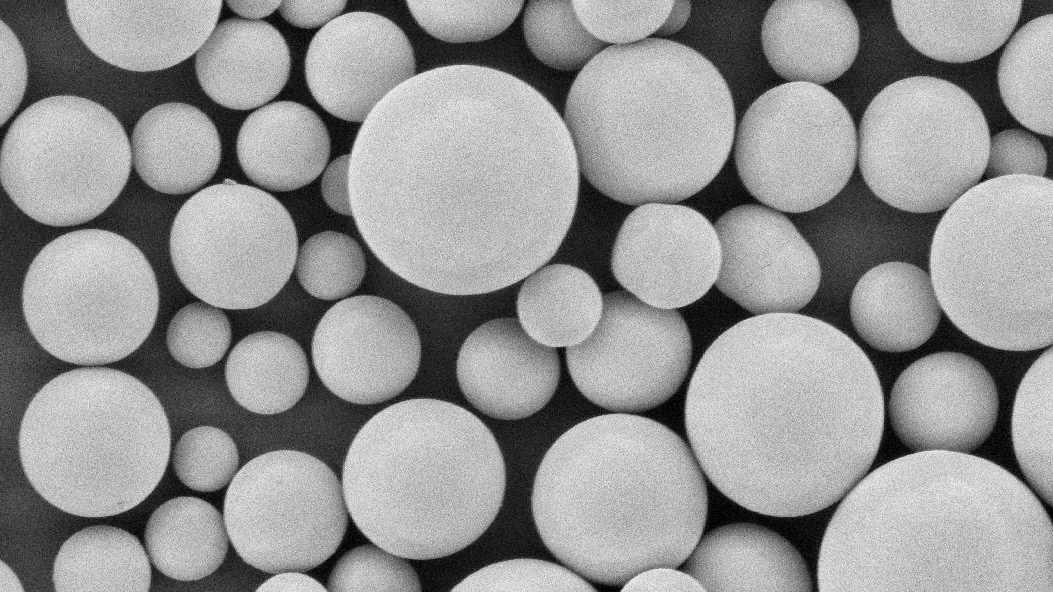

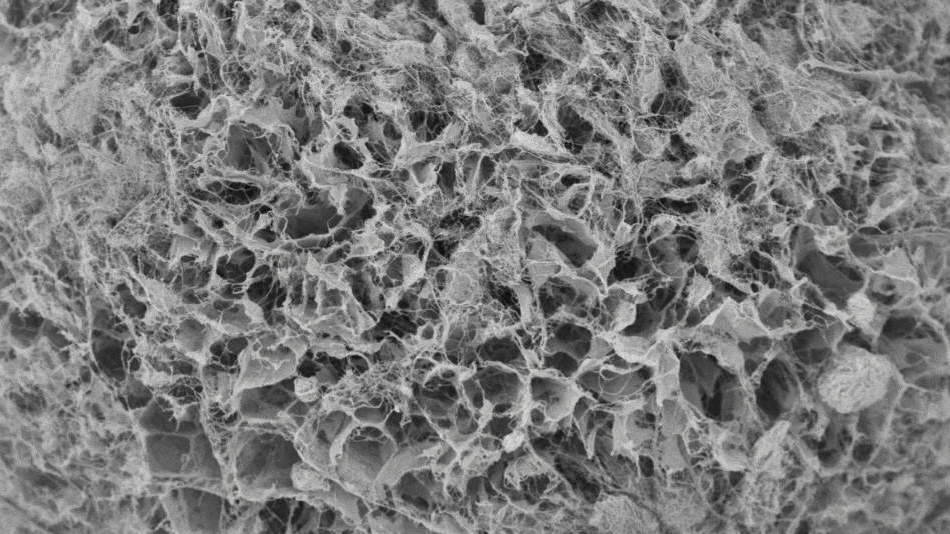

Spray coolers and freeze granulators, like spray dryers, are energy-intensive production processes. Spray coolers produce spherical granules by atomizing a molten liquid material into a cooling gas for the solidification of the droplets. Energy is consumed by the heat source required for the raw material melting process and the cooling source used to solidify the droplets followed by conditioning process at the product recovery line. Freeze granulators require heat of solidification to freeze the atomized droplets and heat of sublimation required to freeze dry the frozen granules. In these processes, as with spray dryers, we aim to reduce energy consumption and operation costs by adopting an optimal heat exchanging system and insulation based on the optimal heat balance, and designing a layout with short heat transfer distances.

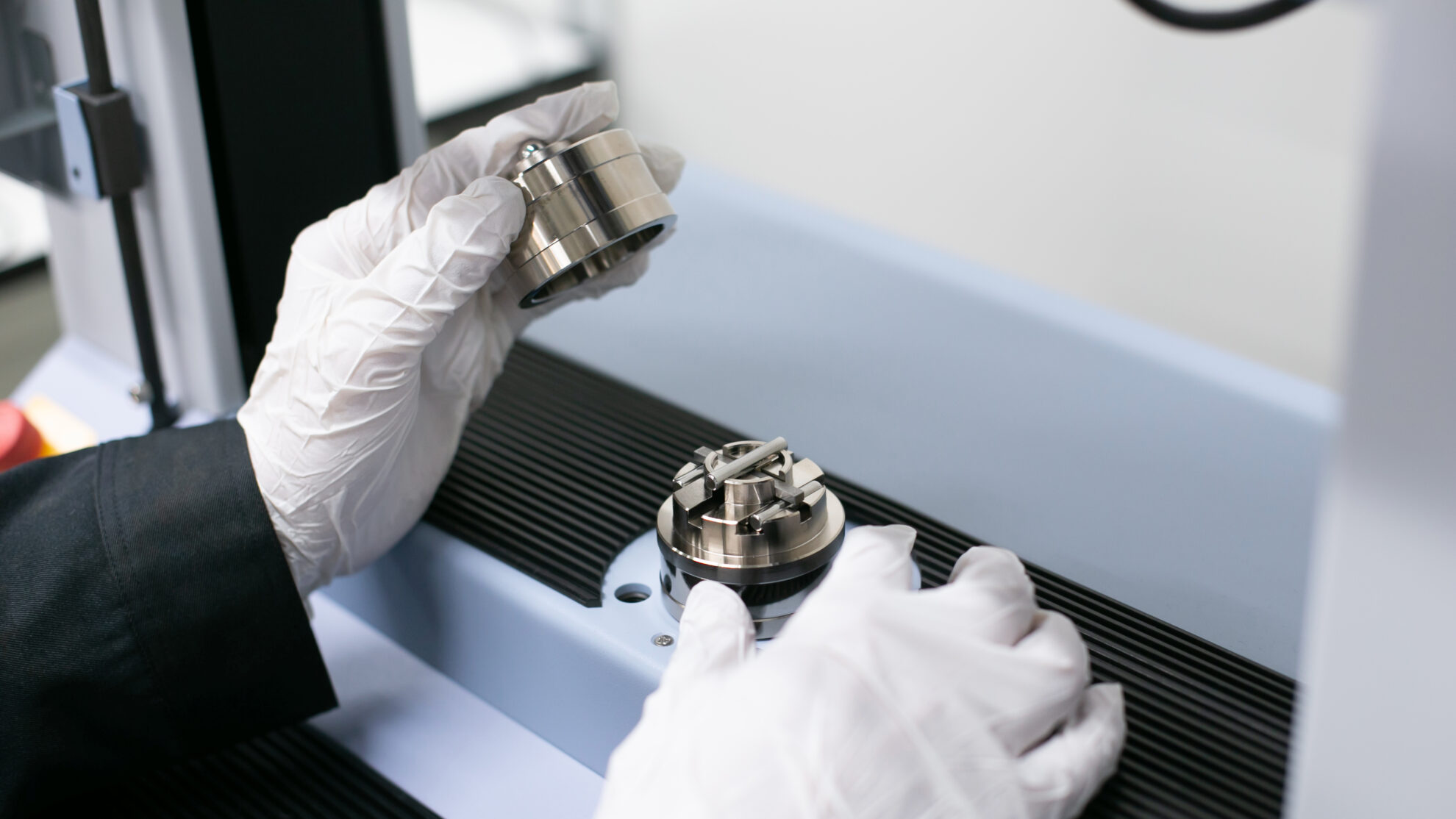

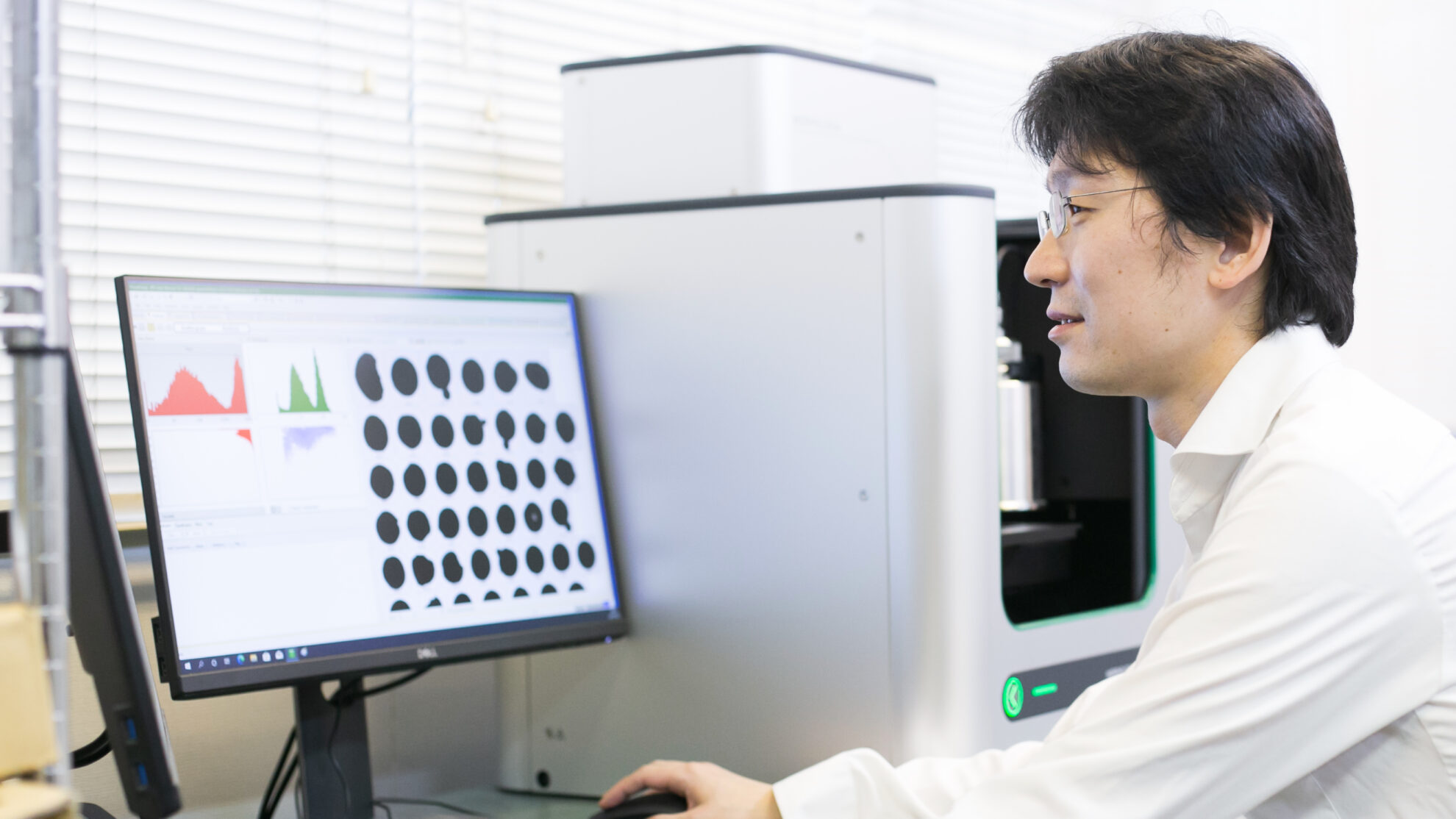

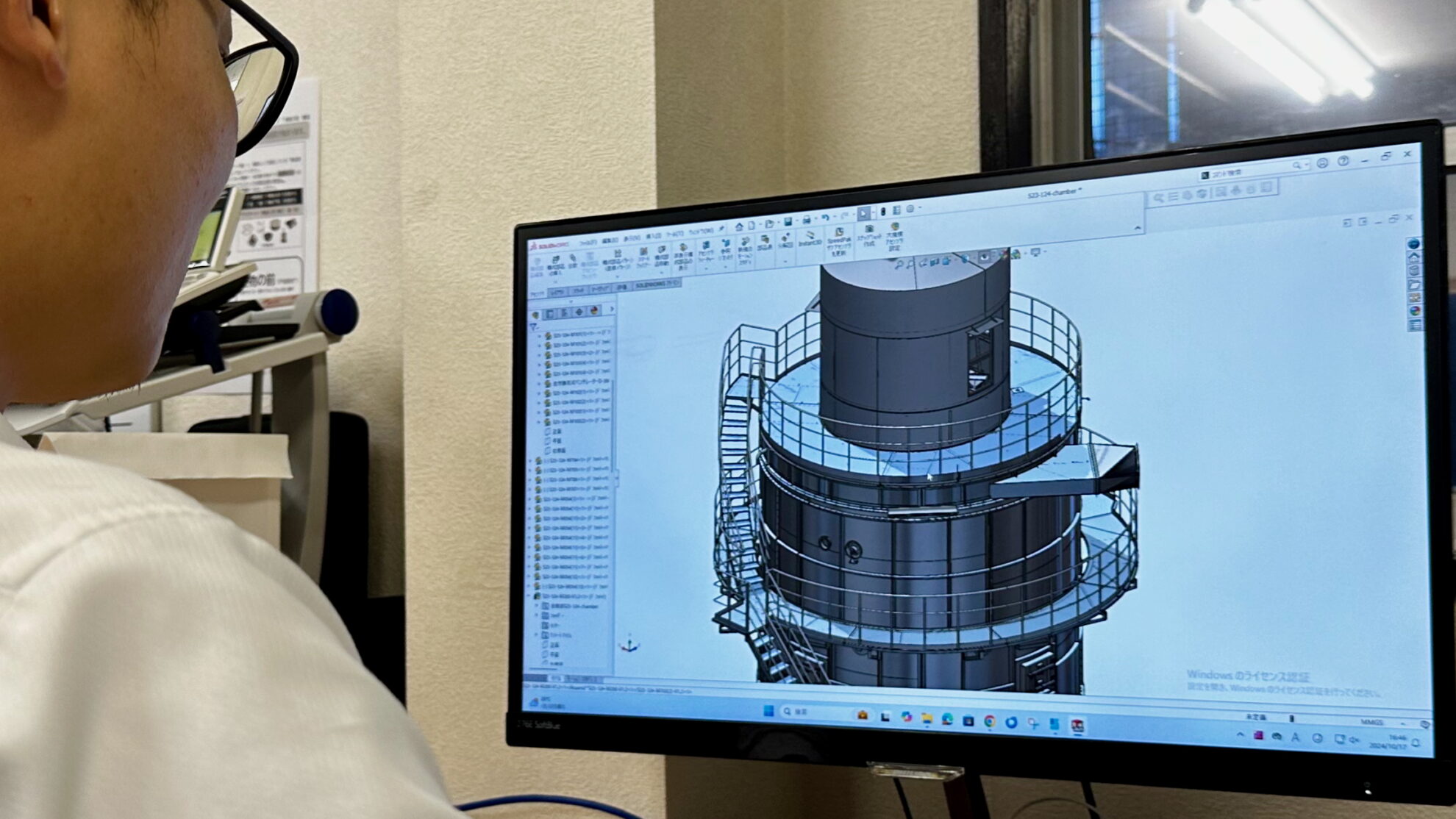

Based on our accumulated technology, we provide spray dryers, spray coolers, and freeze granulators with energy-saving designs. By maximizing energy efficiency, we create a powder manufacturing processes that are both environmentally and cost-friendly. In addition, we not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand under the partnership with T.S.K. Engineering. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements / Contract Powder Processing).