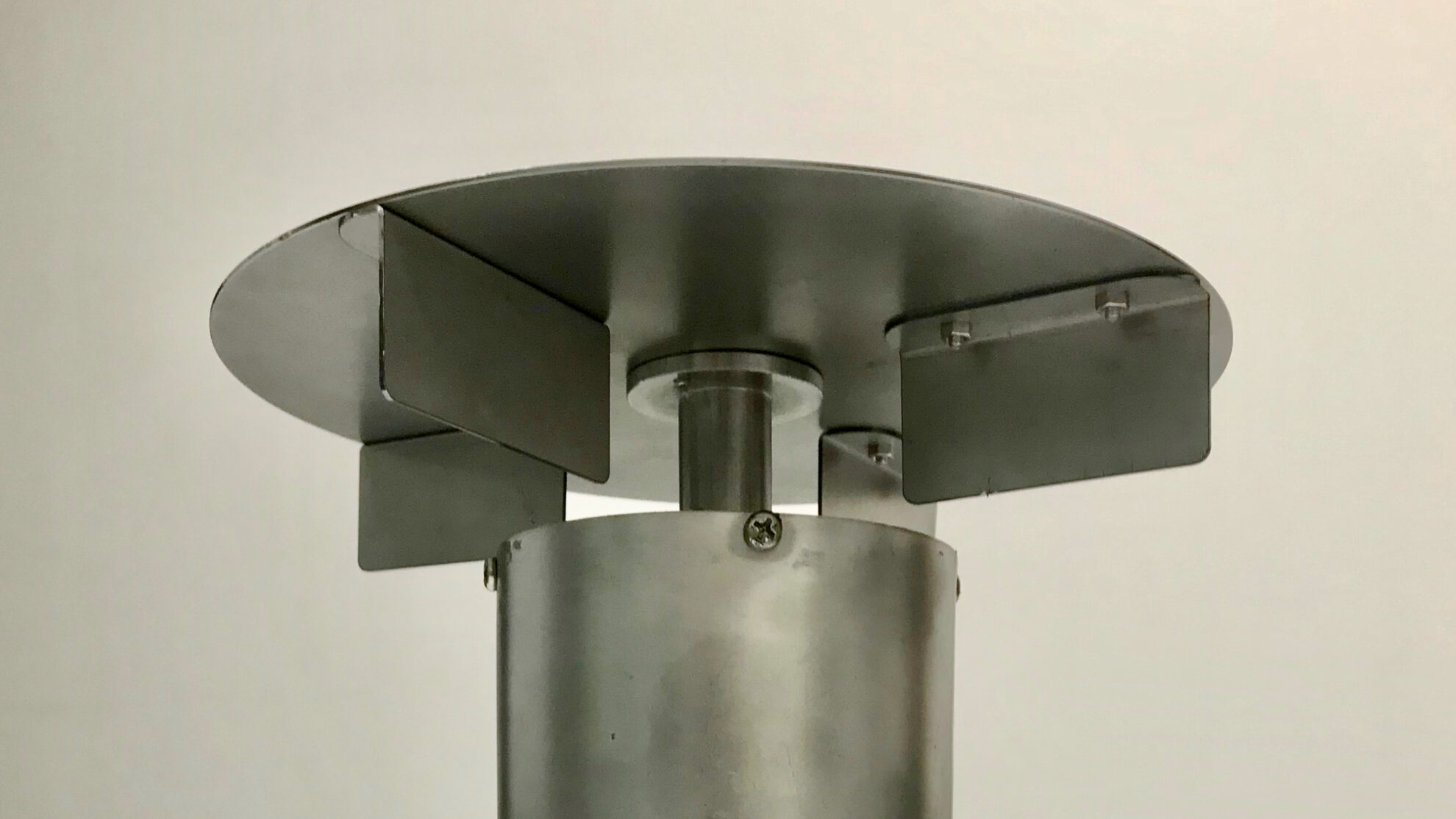

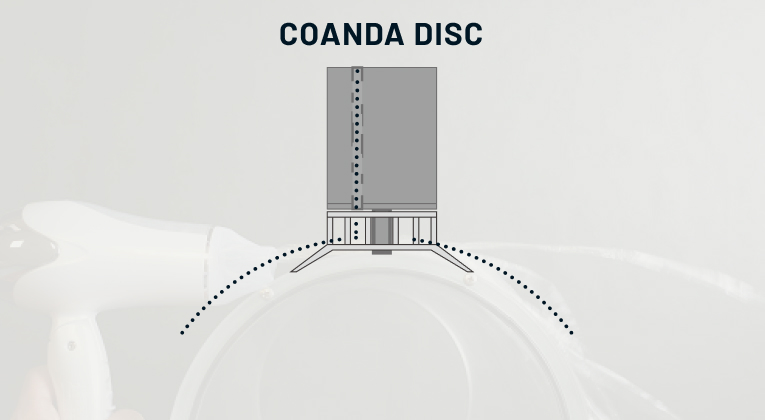

Our patented Coanda Disc is a rotary atomizer disc that applies the Coanda effect, in which a fluid jet is attracted and followed to a nearby curved surface. Compared to conventional rotary atomizer discs, the production efficiency in spray drying, spray cooling, and freeze granulation can be increased.

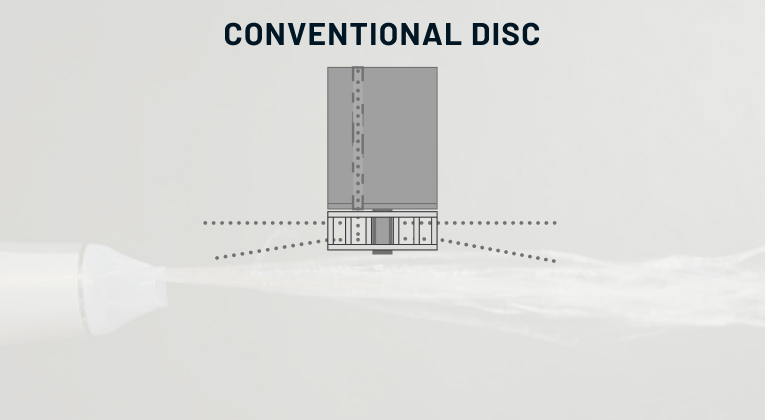

The atomization pattern of droplets from a rotary atomizer using a conventional disc is horizontal due to the action of centrifugal force. Therefore, the diameter of the process chamber must be of a size that allows the droplets to solidify before adhering to the chamber inner wall (e.g. Spray drying is evaporation, spray cooling is solidification, freeze granulation is freezing and solidification). For processes that produce larger particles, the rotational speed should be set lower in order to create a larger droplets. In that case, the time required for droplet solidification becomes longer and the chamber diameter needs to be designed wider in size. The Coanda effect, discovered by Romanian engineer Henri Coanda, is being applied for creating high lift force by flowing jets over the wings of an aircraft. The Coanda disc has a dome-shaped design extending downward in a curved shape, so that the atomization pattern, which is normally horizontal, is directed downward. This effect can increase the droplet fall distance and it allows for the efficient use of chamber space. In other words, assuming a production process with the same liquid material, particle size, and feed capacity is introduced, by using the Coanda disc, the chamber size can be smaller, leading to a reduction in process installation costs. Alternatively, by adopting Coanda discs in existing production processes, it is possible to increase the feed capacity or produce products with larger particle sizes.

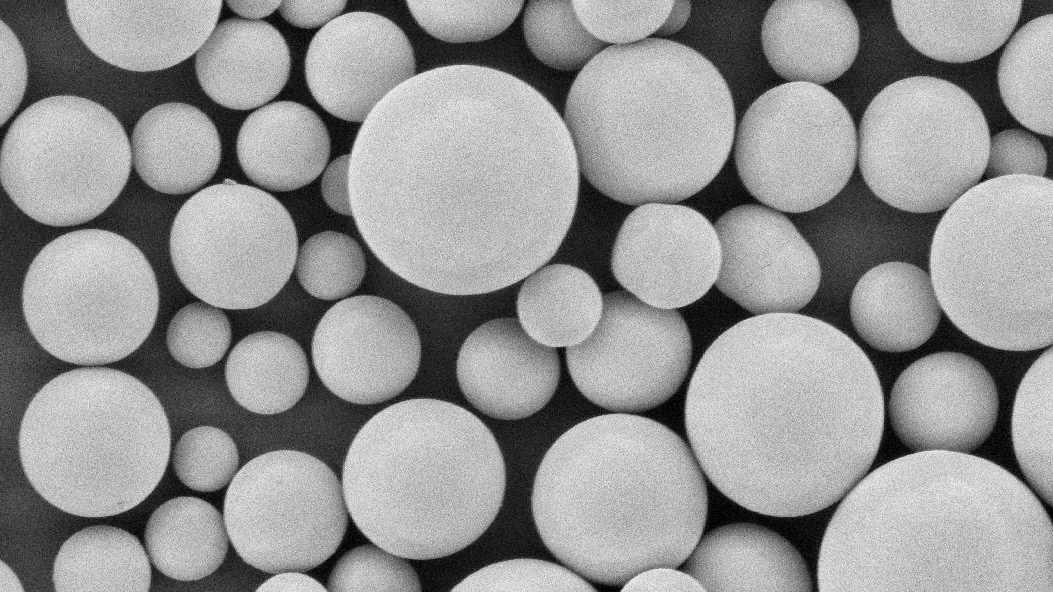

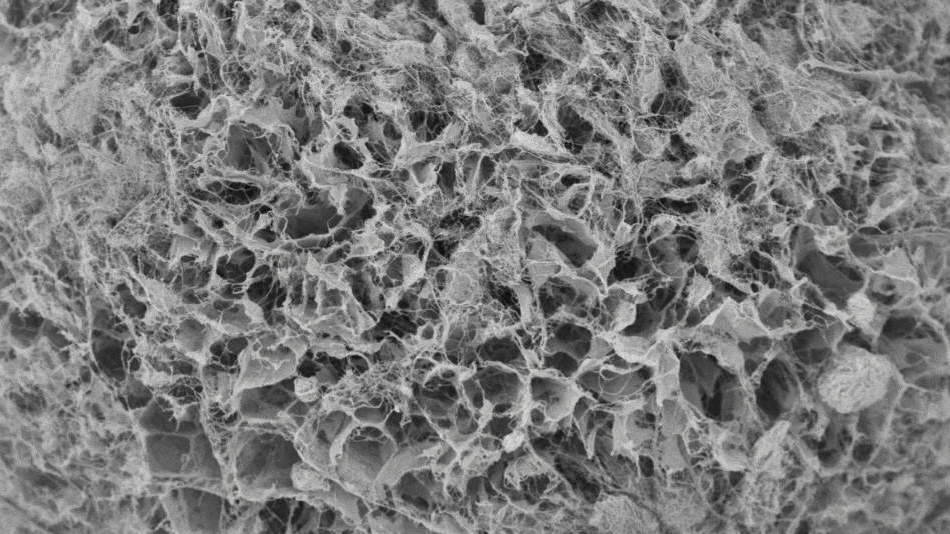

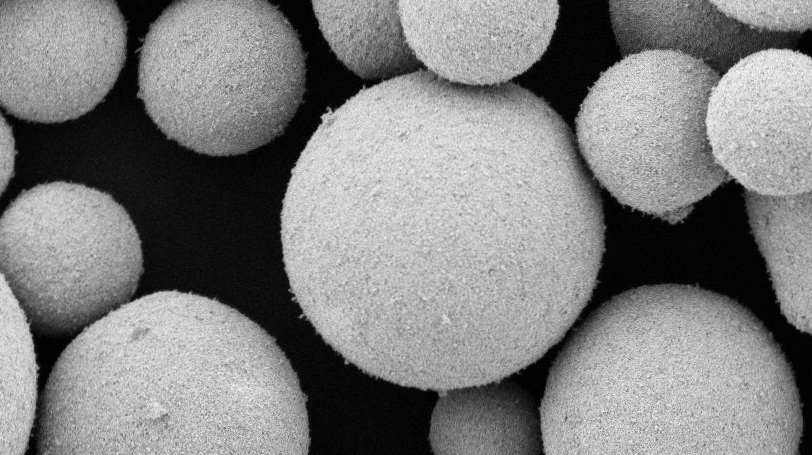

Through joint research with Tokyo University of Science, we have conducted repeated experiments using CFD simulations and high-speed cameras, and have developed the shape that maximizes the Coanda effect. In demonstrations conducted in-house and jointly with our customers, we succeeded in increasing the yield rate of fine ceramic materials such as alumina and silicon carbide, as well as food applications such as dextrin and saccharides. Our Coanda disc can reduce product adhesion inside the process and improve your production yield.

Our spray dryers, spray coolers, and freeze granulators can be equipped with Coanda discs. Based on our accumulated technologies, we provide optimal manufacturing processes. In addition, we not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand under the partnership with T.S.K. Engineering. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements / Contract Powder Processing).