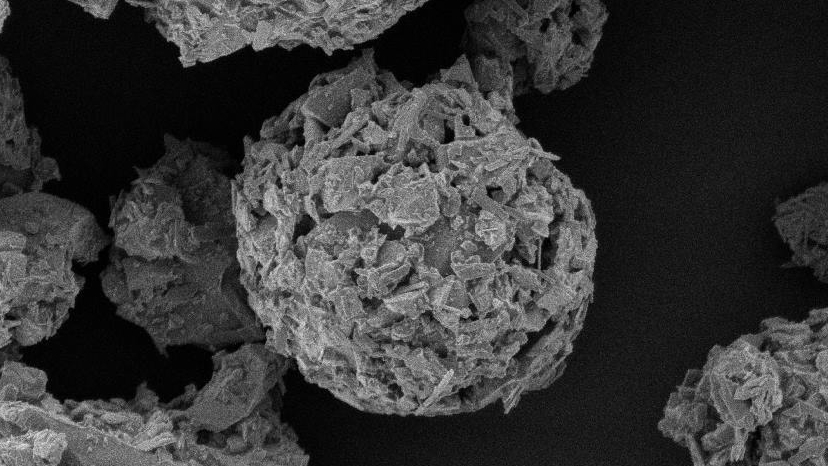

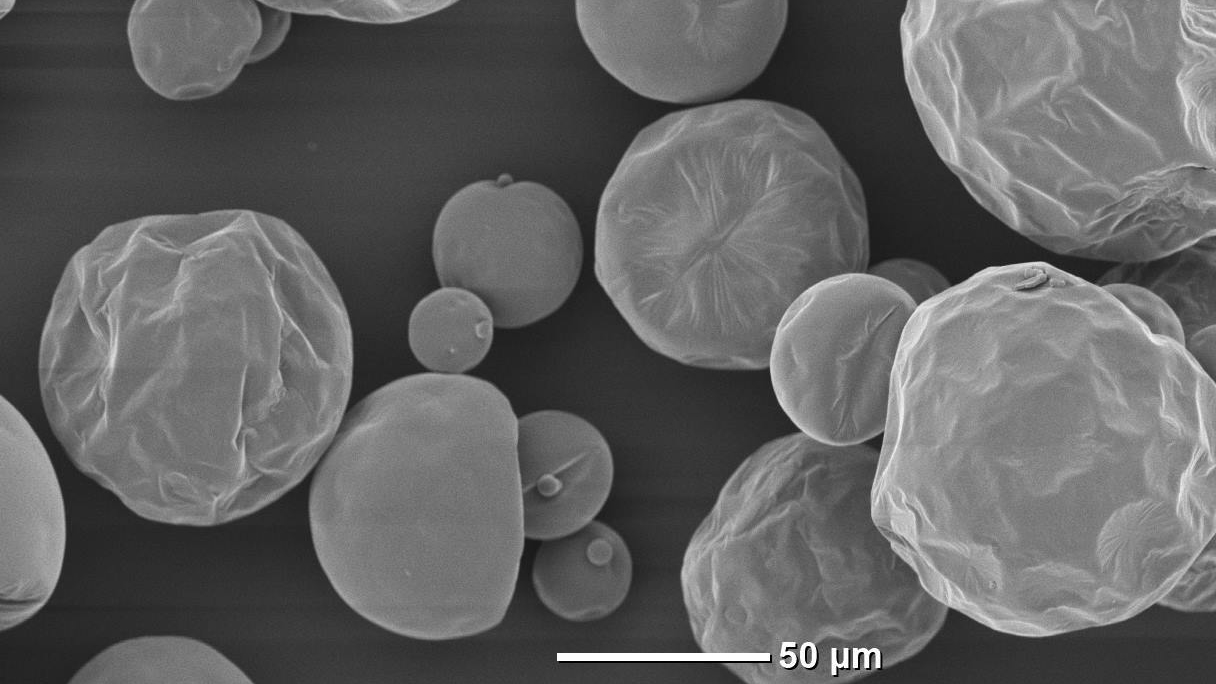

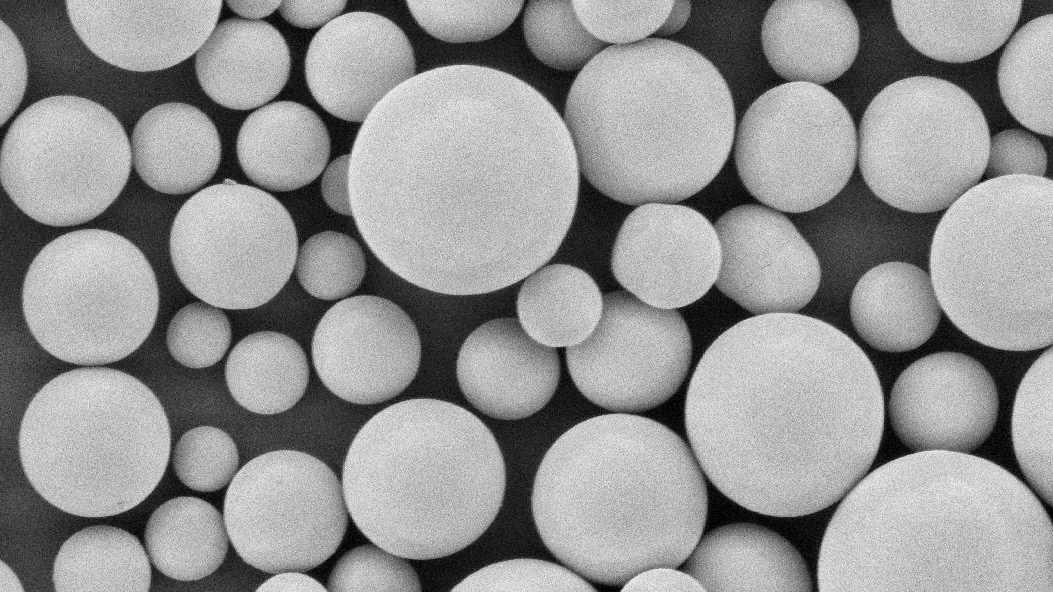

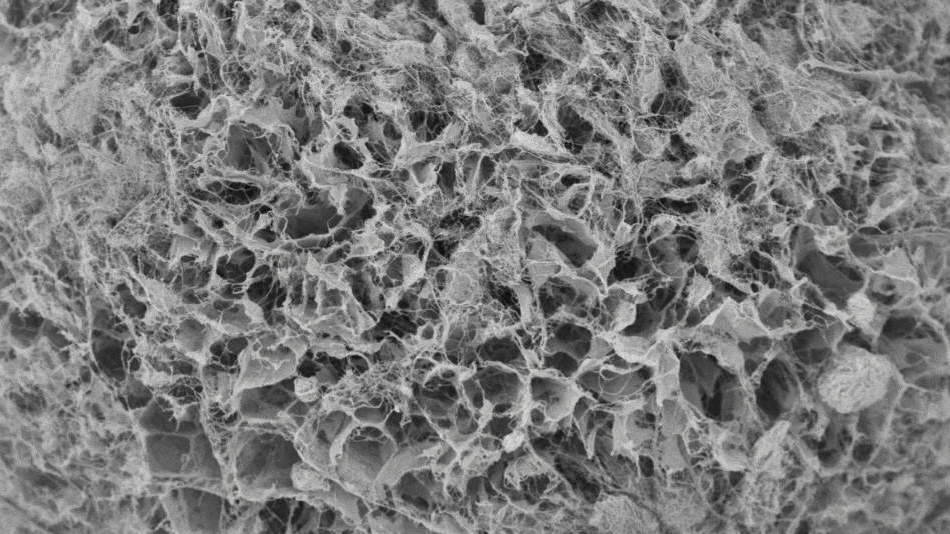

Cleaning processes in food and pharmaceutical industries are extremely important in ensuring product quality and safety. High level of hygiene is required in the powder manufacturing processes such as spray dryers, spray coolers, and freeze granulators, as well as culture tanks and fermenters.

CIP (Clean-In-Place)

CIP is a process that automatically cleans process lines that come into contact with raw materials during the manufacturing process, such as pipelines, containers (chambers, tanks, etc.), ancillary equipment, sensors, etc., without disassembly. Cleaning equipment such as 3D nozzles, push-out nozzles, and shower balls are placed throughout the process to clean the inside of the process lines with a properly designed cleaning program. By introducing CIP, there is no need to disassemble and assemble the process lines, making it possible to shorten the cleaning time and save labor costs. CIP also prevents contamination from outside, improving and stabilizing hygiene standards.

COP (Clean-Out-of-Place)

COP is a process in which process lines are disassembled during the cleanning operation. In general, COP is selected for small-scale, simple-structured processes that involve complex shapes that cannot be completely cleaned using CIP. Since cleaning is performed manually, there is a risk of variations in cleaning quality and contamination from the outside.

Although CIP systems require higher costs from a CAPEX perspective, CIP has many advantages over COP from an OPEX and quality control perspective. In either case, the production process must be sanitary. If for some reason the structure of the process cannot be sanitary, it will be difficult to maintain hygiene regardless of automatic or manual cleaning.

Our small-scale processes are designed to be easy to disassemble and have excellent sanitary properties, with the consideration of COP operations. Small-scale processes may not be equipped with CIP systems due to budgetary constraints. On the other hand, research institutes that continuously conduct small-batch operations on a wide variety of products and under a variety of conditions sometimes adopt automatic cleaning systems in order to save labor costs. For medium-scale pilot facilities and mass production plants, it is necessary to adopt an appropriate cleaning system, taking into consideration the installation cost and operation cost of the cleaning system, as well as the required cleaning quality level. When implementing a CIP system, the process design should include the cleaning system in advance. We consider process specifications and raw material characteristics to determine the optimal cleaning system and operating program. A typical CIP system includes water, acid, and alkali storage tanks, buffer tanks, liquid pumps, process pipe lines, cleaning nozzles, and various sensors. A cleaning process generally start with rough cleaning with hot water and followed by alkaline cleaning, acid cleaning, hot water rinsing, final rinse, and drying. A properly designed cleaning system is required to avoid wasting operational costs such as cleaning chemicals and cleaning time. In order to carry out CIP effectively, comprehensive engineering is required, such as defining chemical and physicochemical cleaning specifications according to the characteristics of the raw material, and selecting cleaning equipment suitable for the structure of production processes. Depending on the characteristics of the raw material and the structure of the production process, it may be possible to construct a cleaning system that is more hygienic and stable than a fully automatic CIP system by partially adopting COP and separating it from automatic cleaning of the entire process (semi-CIP system).

Based on our accumulated technology, we provide the optimal cleaning process for spray dryers, spray coolers, and freeze granulators. In addition to hygiene and environmental compatibility, we also carefully consider the system investment cost and operating costs. By performing circulation cleaning as much as possible, we maximize the reuse of resources and create an efficient cleaning system that does not waste utilities and cleaning chemicals.

Our spray dryers, spray coolers, and freeze granulators can be equipped with various cleaning systems. Based on our accumulated technologies, we provide optimal manufacturing processes. In addition, we not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand under the partnership with T.S.K. Engineering. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements / Contract Powder Processing).