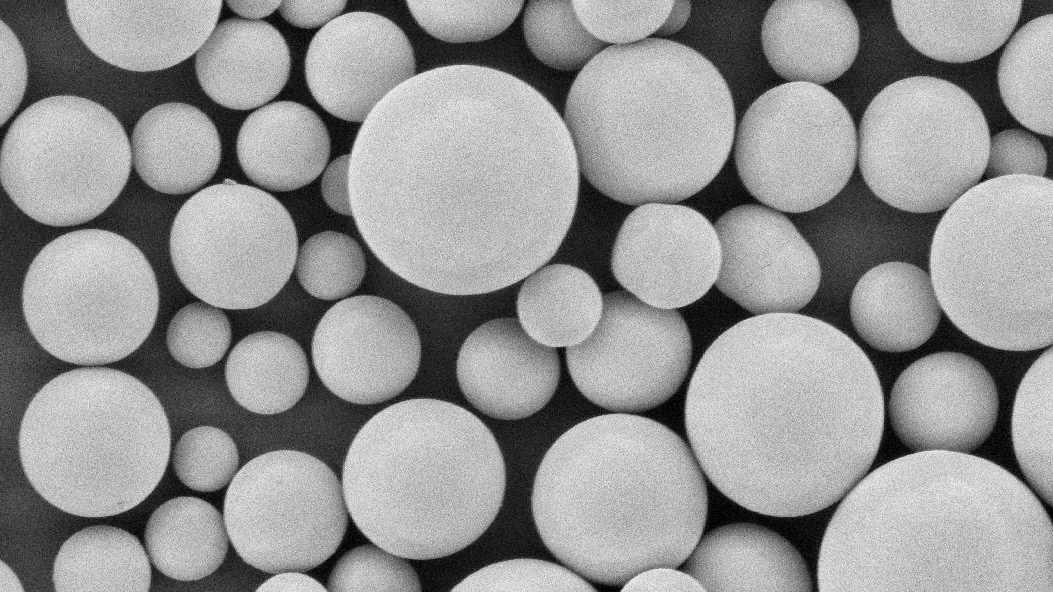

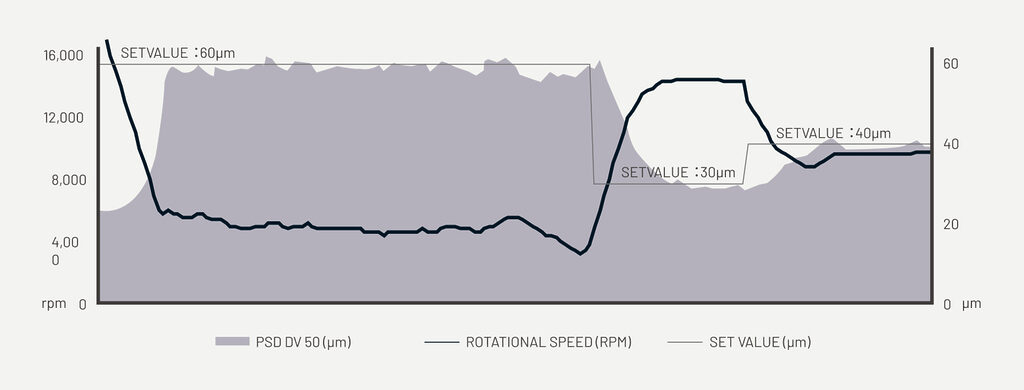

Our patented technology, the automatic PSD control atomizer system, measures the particle size of the powder flowing through the process in real time, and the rotational speed of the rotary atomizer is automatically adjusted by our original algorithm. Since the particle size is automatically controlled as a set value without fixing the rotational speed, the system can precisely keep the set PSD during the operation.

Currently, the mainstream for rotary atomizer controls in operation around the world is to fix the rotational speed at an arbitrary set value. Fixed speed operations run the risk of the product deviating from the targeted particle size range if other environmental conditions change. Most of the manufacturers control powder quality by periodically measuring particle size by ex-situ. In-situ real-time monitoring is an effective way to improve quality stability. Product loss can be avoided by automatically controlling PSD in real time. There are quality control parameters in powder processing using rotary atomizers. In terms of raw materials, concentration, viscosity, pH, etc. of liquid materials are to be monitored. Additionally, if the raw material is a suspension or slurry, the physical properties and dispersibility of the primary particles should also be considered. If there is a difference in quality between batches during the liquid material manufacturing process, it will affect the PSD of the powder processed. Process conditions also change depending on the weather and environment of the installation location.

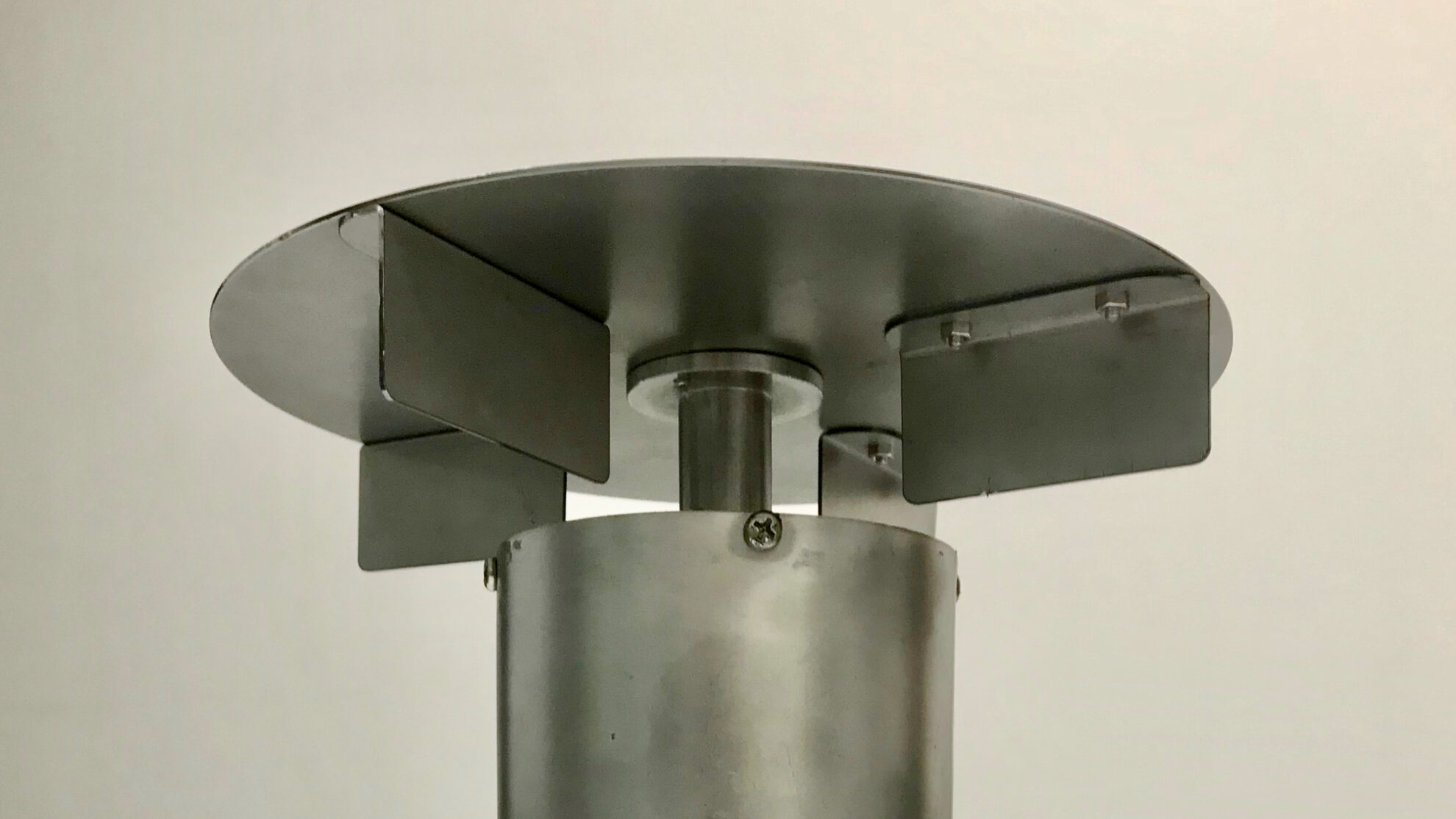

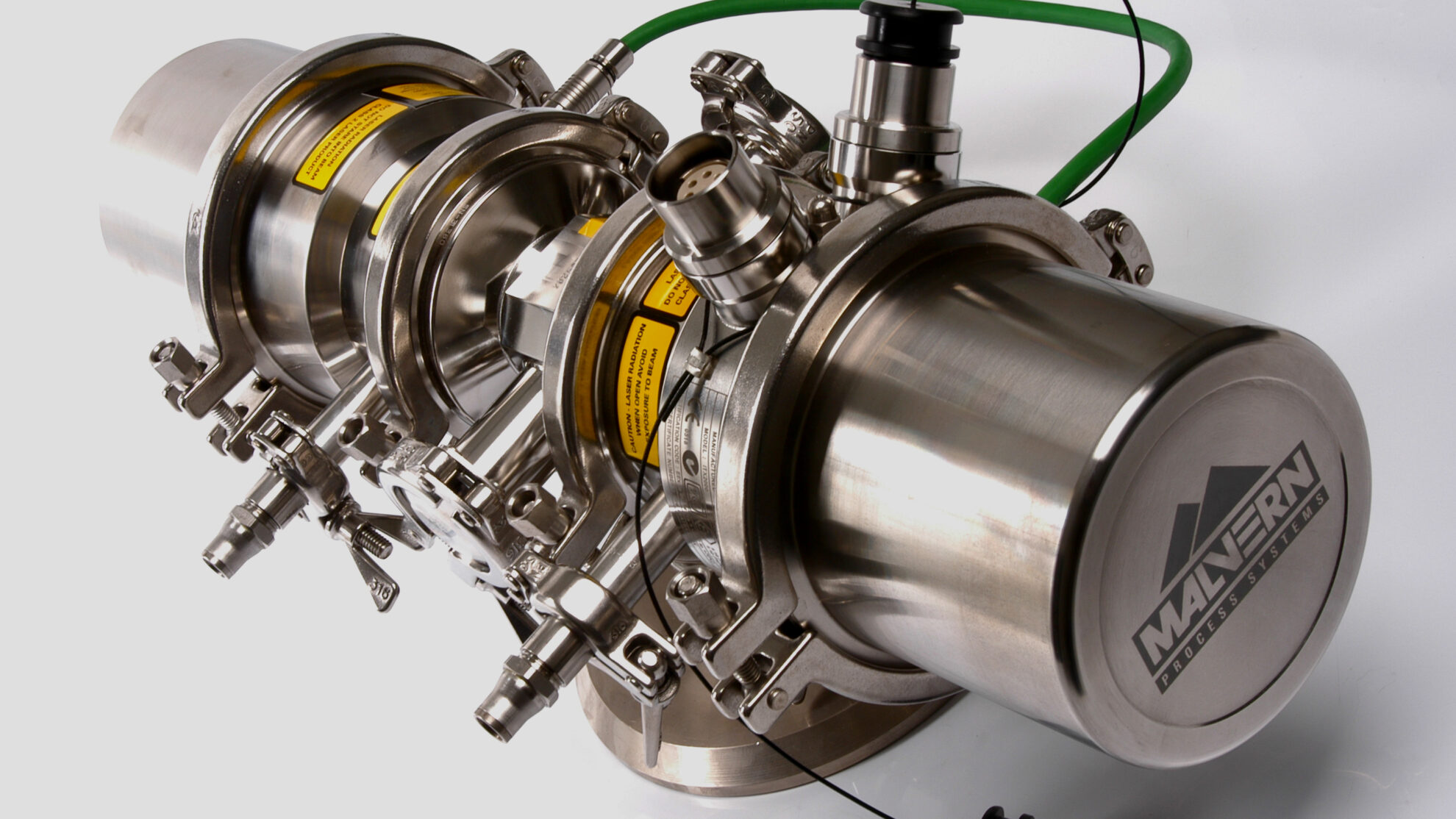

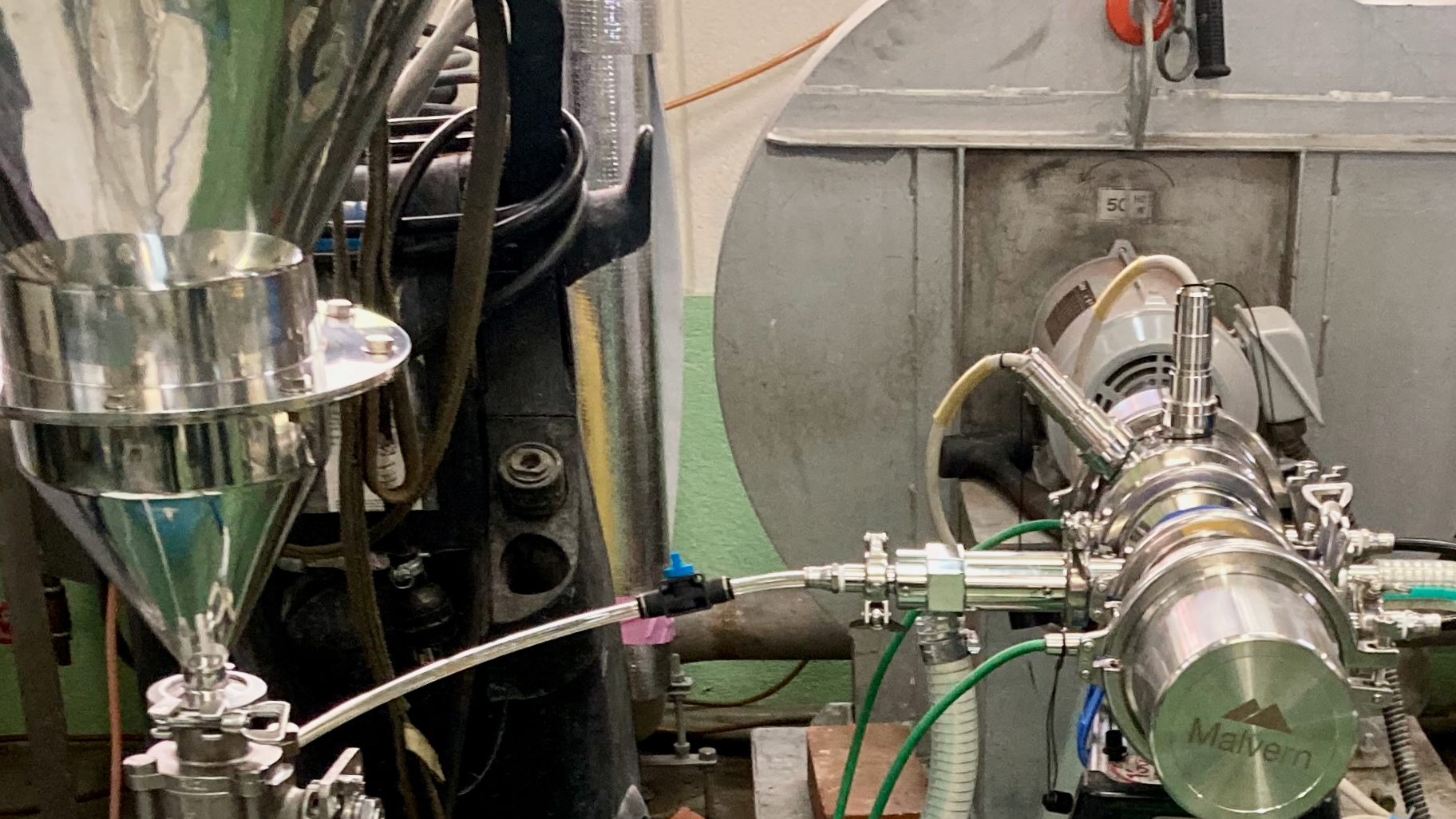

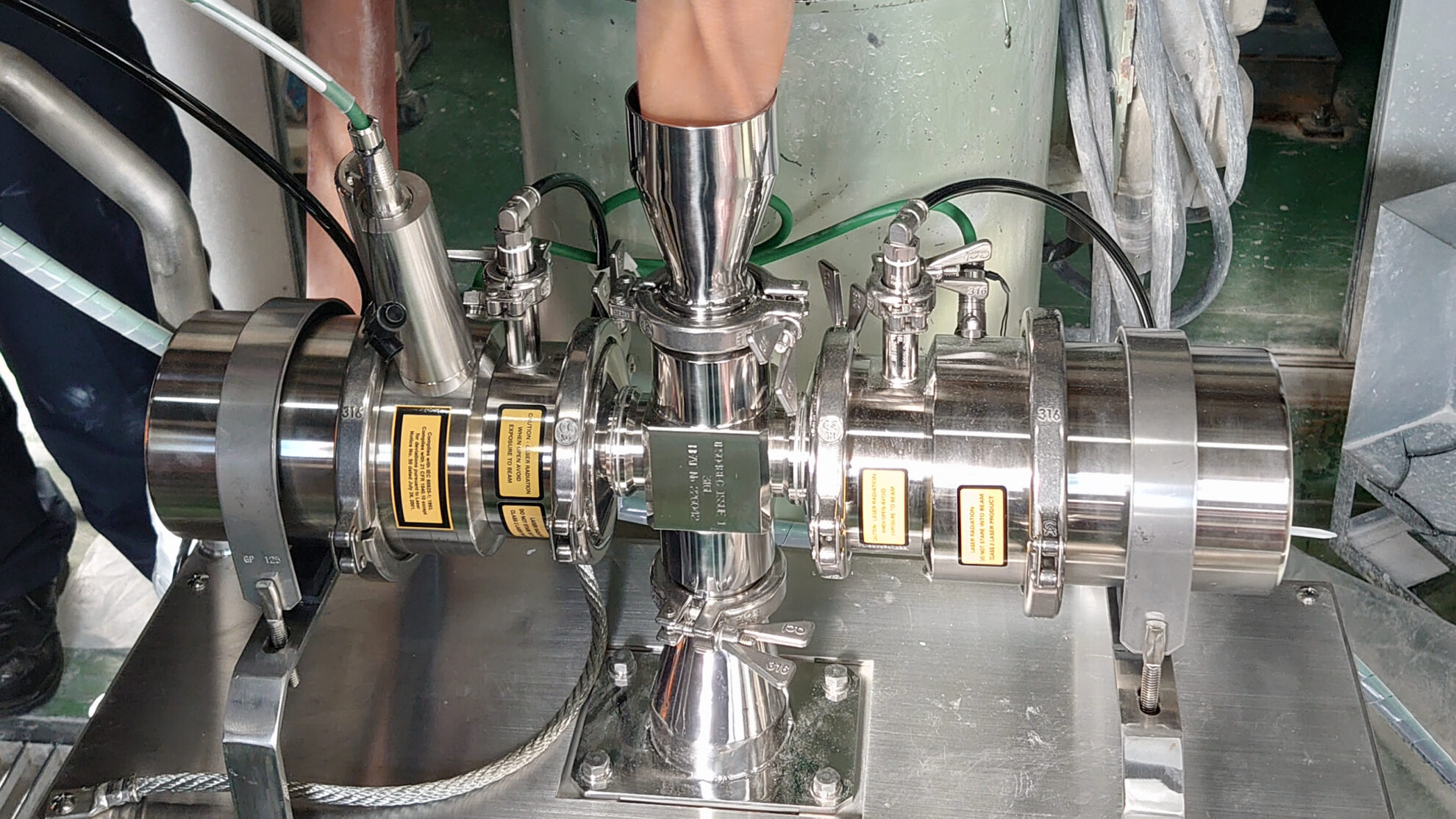

We use Malvern Panalytical’s Insitec for our system. The Mie theory laser diffraction method adopted by ISO is used to measure particles in real time in the particle size range of 0.1 to 2,500 μm. The angularly scattered light intensity data from the laser is analyzed and the particle size distribution is calculated as the diameter of a volume-equivalent sphere. A sampling point is installed on the powder collection line to measure the particle size of the flowing powder. The obtained value is fed back to the control of the rotary atomizer, and the rotational speed is automatically adjusted by our patented algorithm. PSD can be precisely controlled with our continuous feedback control system all the time in operation. Powder is a collection of particles in various sizes. Therefore, those sizes are expressed by a “distribution”. Rotary atomizers are an atomization system that can obtain a sharp PSD. However, environmental conditions during the production are not constant. In order to precisely monitor the process and stabilize the powder quality, we can automatically control the PSD instead of the conventional fixed rotational speed.

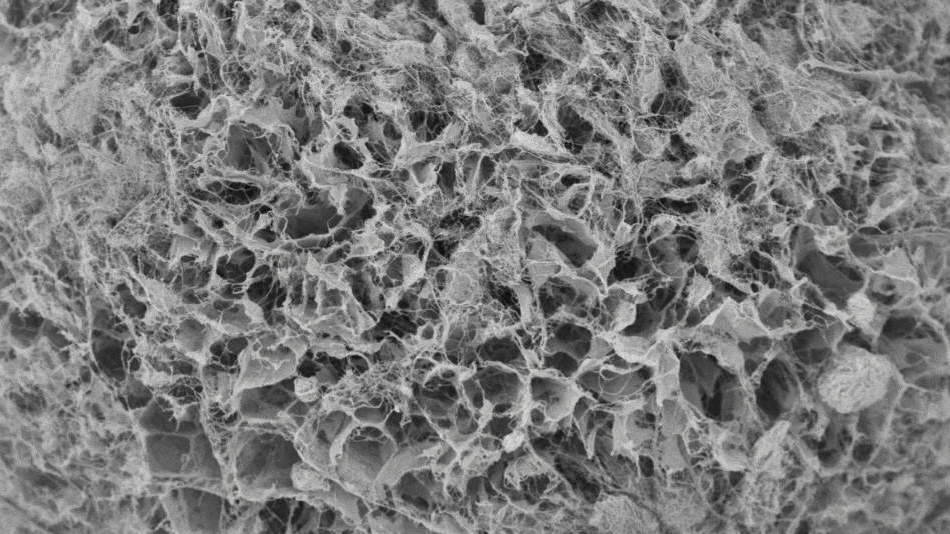

Our spray dryers, spray coolers, and freeze granulators can be equipped with auto PSD control atomizer system. Based on our accumulated technologies, we provide optimal manufacturing processes. In addition, we not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand under the partnership with T.S.K. Engineering. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements / Contract Powder Processing).