Index

Liquid atomization

Liquid atomization is the most important element in particle design for spray dryers, spray coolers and freeze granulators. Liquid materials such as solutions, gels, suspensions, slurries and emulsions are sprayed or atomized into powder manufacturing processes using atomization systems such as rotary atomizers and spray nozzles. A liquid material is atomized and droplets are formed by an atomization system. As droplets become smaller, their specific surface area rapidly increases. Therefore, with a spray dryer, the moisture in the droplets evaporates and dries in a short period of time, ranging from a few seconds to several tens of seconds. Similarly, droplets are solidified within a short period of time in spray cooling and freeze granulation. The particle size and shape of powders are strongly influenced by the shape of droplets during atomization. Therefore, the first step for designing a powder manufacturing process is to determine the right atomization system and operating conditions that can produce the desired granule quality.

Liquid atomization has the following effects.

Surface tension

Surface tension causes the formation of spherical droplets.

Increased surface area

The total surface area of a uniform spherical droplet with a droplet diameter of 1/N is multiplied by N. Therefore, heat transfer and chemical reactions are promoted.

Increase in number of droplets

The number of uniform spherical droplets with a droplet diameter of 1/N is N3. Therefore, it can be uniformly distributed over a wide spatial range.

Droplet mass reduction

A uniform spherical droplet with a droplet diameter of 1/N has a mass of 1/N3. Therefore, the momentum exchange between a droplet and a gas is enhanced.

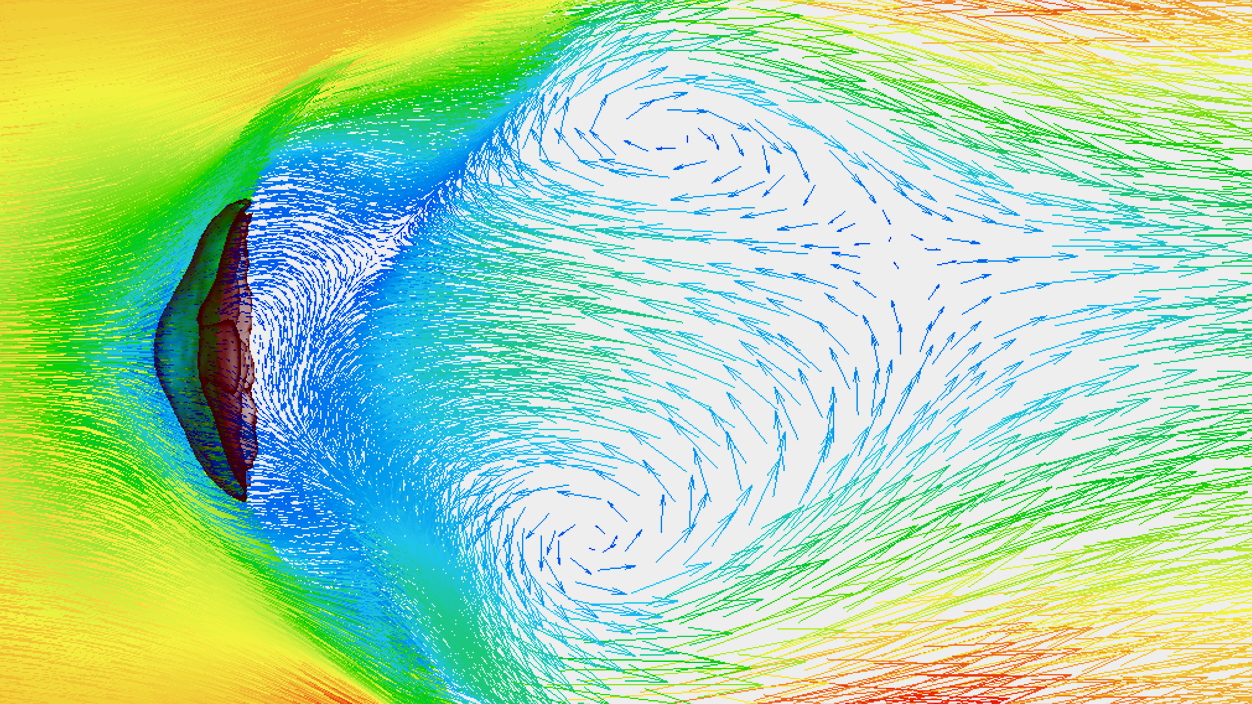

A liquid supplied to an atomization system is destabilized by the impact of internal and external energy given, causing it to flow, deform, and breakup. A supplied liquid becomes more unstable due to turbulence in the liquid as the flow rate increases. Furthermore, the addition of external forces such as air causes fragmentation, forming ligaments and droplets. External forces mainly include shear forces and forces acting on the interface between the liquid and the outside air (surface tension and negative pressure due to airflow). A state in which most of the liquid flow becomes droplets is called an atomization flow. Droplets repeat re-splitting during liquid disintegration process, becoming finer and forming an atomization flow. In theory, re-splitting is repeated until the droplet’s surface tension balances out the force caused by the irregular turbulence of the external air.

The main factors in liquid atomization are the physical properties of a liquid and a gas and the energy added externally.

Physical properties of a liquid and a gas

Density ( ρ ), Viscosity ( μ ), Surface tension ( σ ), Specific heat ( c ), Thermal conductivity ( λ ), Temperature diffusivity ( α ), etc.

Energy added externally

Liquid flow rate ( ν ), Atomization pressure ( p ), Atomization speed ( ν ), Rotational speed ( N ), Temperature ( T ), etc.

Energy added externally works to make a liquid unstable, while the liquid works to resist deformation and return to its original stable state. The stability of a liquid in an atomization flow is derived from the dimensionless numbers of the liquid’s inertial, viscous, and surface tension forces. Typical dimensionless numbers include the Reynolds number ( Re ), Weber number ( We ), jet number ( Je ), stability number ( St ) derived from Reynolds number and Weber number, and Ohnesorge number ( Oh ).

Atomization properties are influenced not only by an atomization system but also by physical properties of a liquid material and process conditions. In terms of physical properties of a liquid, density, viscosity, pH, dispersion, and properties of primary particles in the case of a slurry or a suspension are affected. In the process conditions, the design of a process, process gas temperature, process gas flow, internal pressure, etc. are the properties to be affected. Therefore, it is important to consider the characteristics of the liquid material and manufacturing process and determine the atomization system and atomization conditions that will yield the desired granule quality.

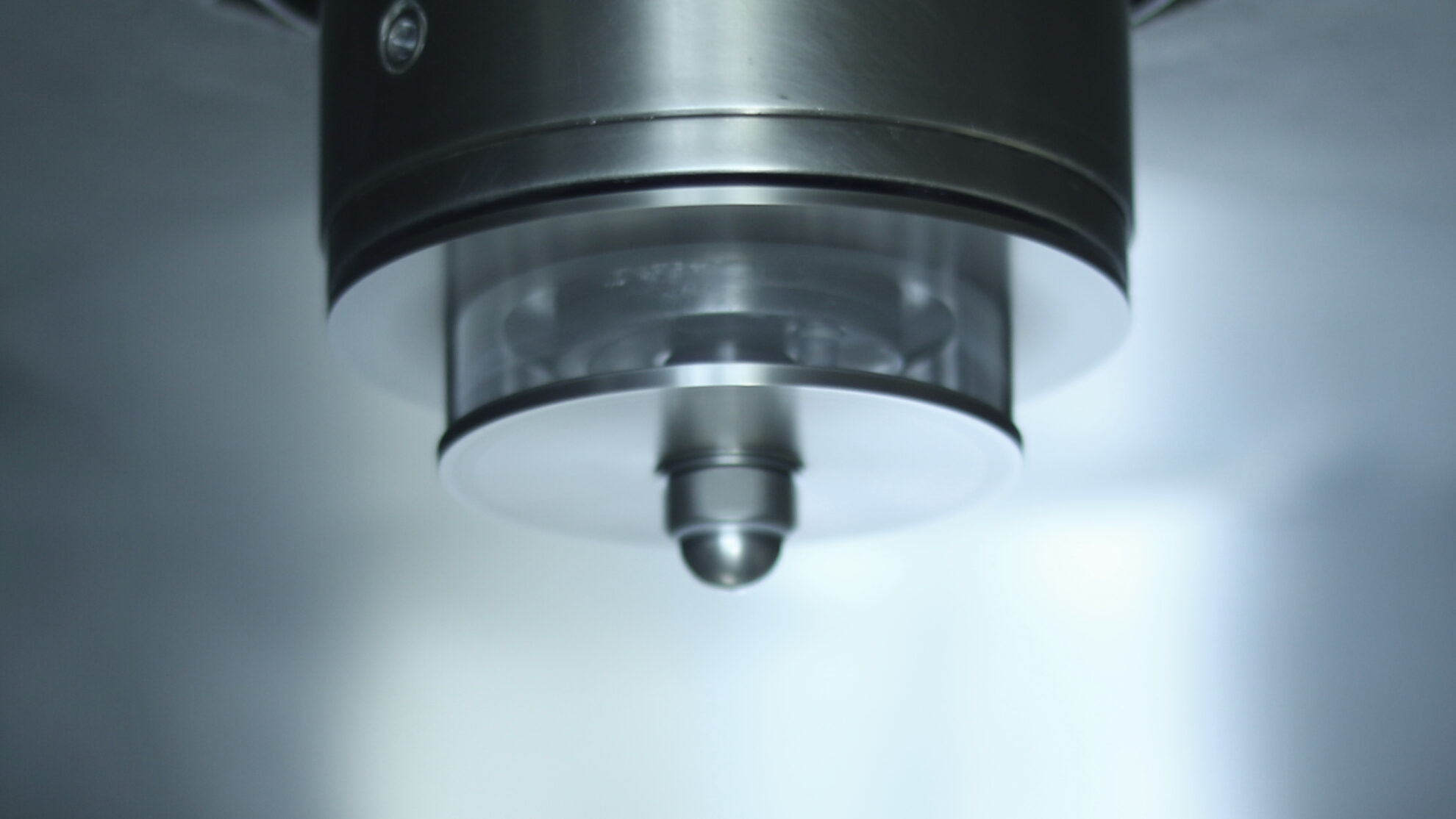

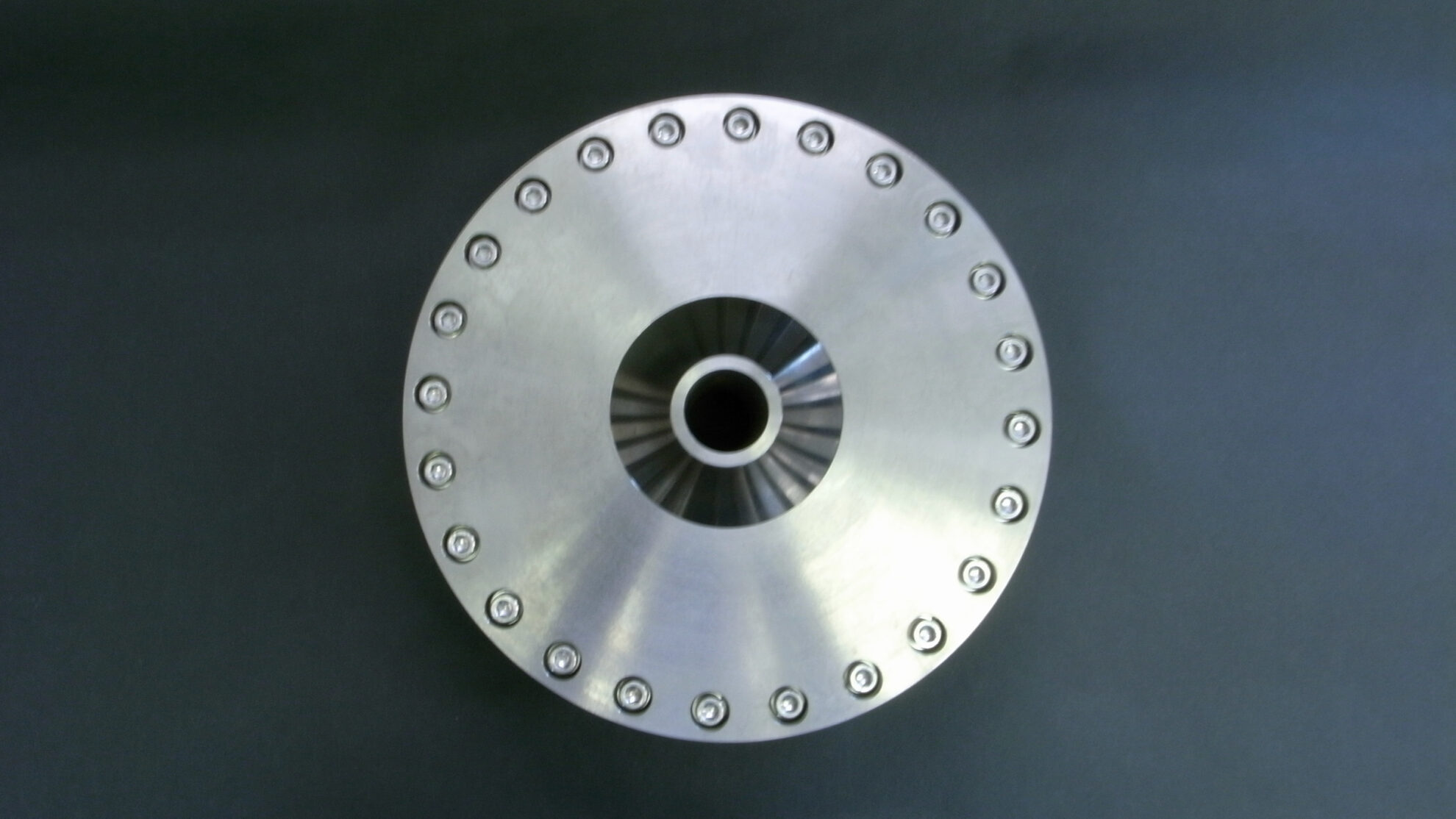

Rotary atomization

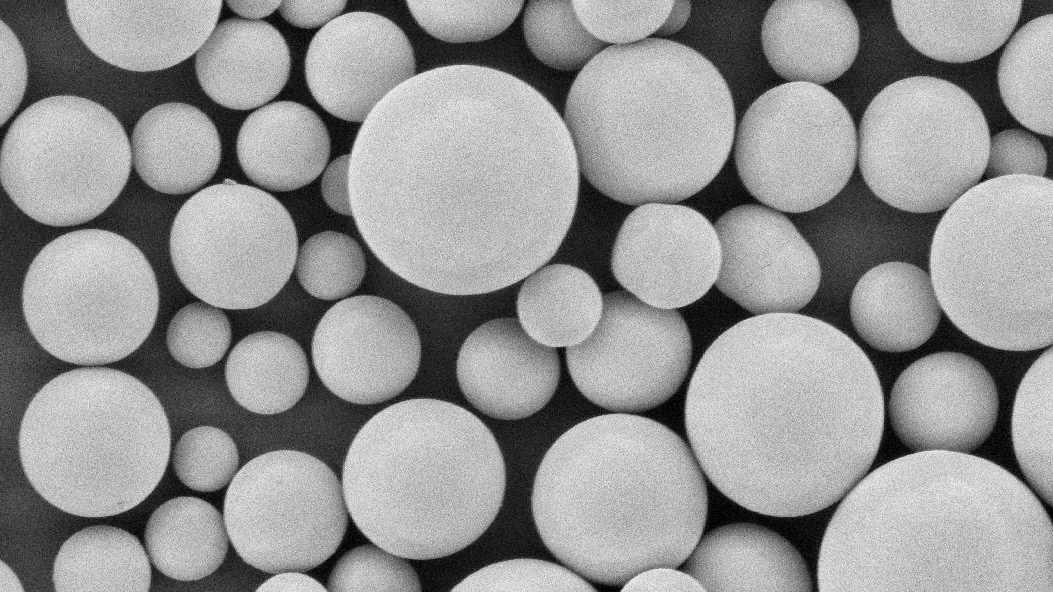

Rotary atomization is an atomization system in which liquid is supplied to a disc that rotates at high speed and atomized from the periphery of the disc by centrifugal force. It is also called centrifugal atomization because it uses centrifugal force from high-speed rotation to atomize a liquid material. A continuously supplied liquid material becomes liquid thin film that reaches the periphery of the disc and create droplets by the destabilization of the liquid. A state of liquid atomization is designed and controlled by the centrifugal force determined by the diameter and rotational speed of the disc, disc shape, liquid feed rate, and physical properties of the liquid material such as density, viscosity and surface tension. The droplet size range for rotary atomizers in general is from 20 micrometers to several millimeters. The particle size range as a powder is 10 to 200 μm in spray drying, 20 μm to several mm in spray cooling, and 20 to several hundred μm in freeze granulation. The shape of the droplets becomes spherical thanks to surface tension, resulting in granules with sharp particle size distribution and excellent flowability.

Rotary atomizers

Our rotary atomizers have a maximum capacity of 25 t/h and a rotational speed up to 35,000 rpm, allowing to select the model that best suits your purpose.

Motor drive modes

Two drive modes are available: direct drive and belt drive. We select the most suitable model according to the liquid feed rate, disc size and shape, and rotational speed.

Safety monitoring systems

Rotation sensors, bearing temperature sensors and safety interlock systems are included as our standard system. Vibration monitoring sensors and liquid leakage detection sensors can be added as options.

Control systems

Rotational speed control or Auto-PSD-Control System (patented) can be selected.

Atomizer cooling systems

Air cooling system or oil cooling system can be selected depending on the model.

Discs

A variety of disc models designed in-house including our unique patented disc models can be selected.

Materials

A wide variety of materials including stainless steel, Super Duplex (SAF 2507), titanium, Inconel, Hastelloy C276, or ceramics such as alumina, zirconia, silicon nitride, and silicon carbide are available.

Surface treatments

Tungsten thermal spraying treatment or stainless steel special hardening are available for preventing wear and tear. A special coating treatment to improve the slipperiness of liquid can also be selected.

Shapes

Discs with various shapes can be selected depending on the application and material properties. We have developed a variety of original discs including the Coanda disc (patented) which utilizes the Coanda effect (the effect that fluid is attracted to nearby walls).

Nozzle atomization

Nozzle atomization is an atomization system that atomizes liquid using external energy such as liquid pressure, compressed gas, or ultrasonic waves. Our lineup includes single-fluid nozzle (pressure nozzle) atomization by pump pressure, two-fluid nozzle atomization by mixing and colliding of compressed gas, and ultrasonic nozzle atomization by liquid film vibration using ultrasonic waves. Our state-of-the-art two-fluid nozzle has excellent atomization performance and is capable of atomizing particles in single micron order.

Pressure nozzles

Pressure nozzles, also called single-fluid nozzles, are an atomization system in which liquid is atomized by the pressure of a pump. The liquid flow pressurized by a pump creates a swirling flow within the nozzle chamber and is atomized by being discharged from the nozzle orifice at high speed. The droplet size range for pressure nozzles is typically from 30 μm to a few millimeters. The particle size range as a powder is 15 to 500 μm in spray drying, 30 μm to several millimeters in spray cooling, and 30 to several hundred μm in freeze granulation. The liquid pressure can be set within a wide range. Materials are selected based on wear, corrosion and heat resistance, etc. Our original universal nozzle system is one of our unique technologies that allows to freely adjust the nozzle angles. The system can improve production efficiency and yield by calculating the optimal number of nozzles and feed rate per unit, and designing an appropriate layout according to the process chamber size.

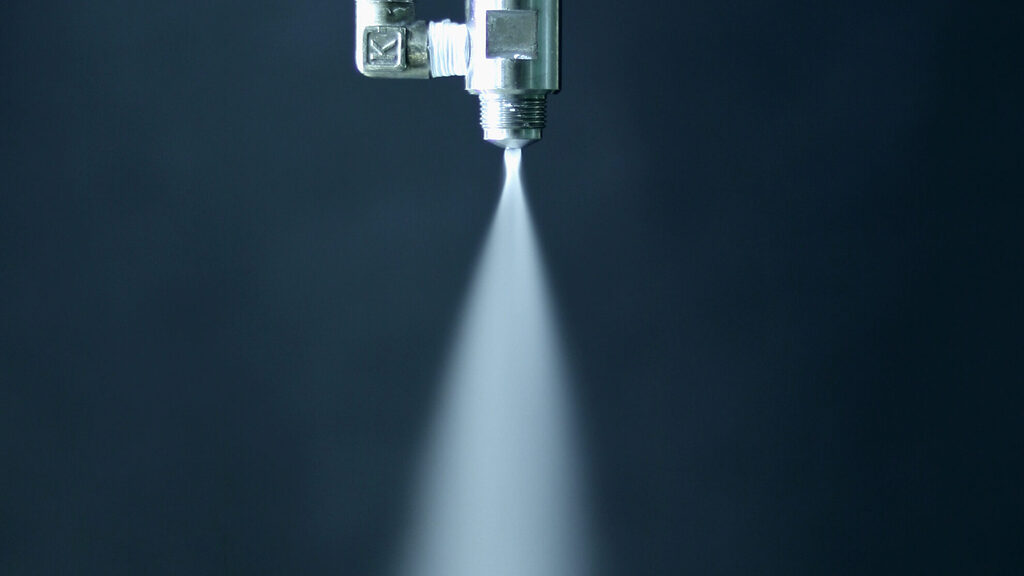

Two-fluid nozzles

Two-fluid nozzles are an atomization system in which compressed gas impinges and mixes with a liquid stream. The liquid flow fed by a pump collides and mixes with the compressed gas flow inside the nozzle. Our state-of-the-art two-fluid nozzle has the same level of performance as multi-fluid nozzles such as four-fluid nozzles, and can atomize to single microns while significantly reducing compressed gas consumption. The droplet size range is typically from a single micrometer to around 70 μm. The particle size range as a powder is from sub-micron to 30 μm in spray drying, from 10 to several hundred μm in spray cooling, and from 10 to several hundred μm in freeze granulation. Spray patterns can be adjusted by the mixture ratio of compressed gas and liquid (gas-liquid ratio). The higher the compressed gas pressure, the finer the atomized droplets are. Our two-fluid nozzles are designed to prevent clogging even for highly viscous materials. The most suitable material is selected by considering wear, corrosion and heat resistance, etc.

Ultrasonic nozzles

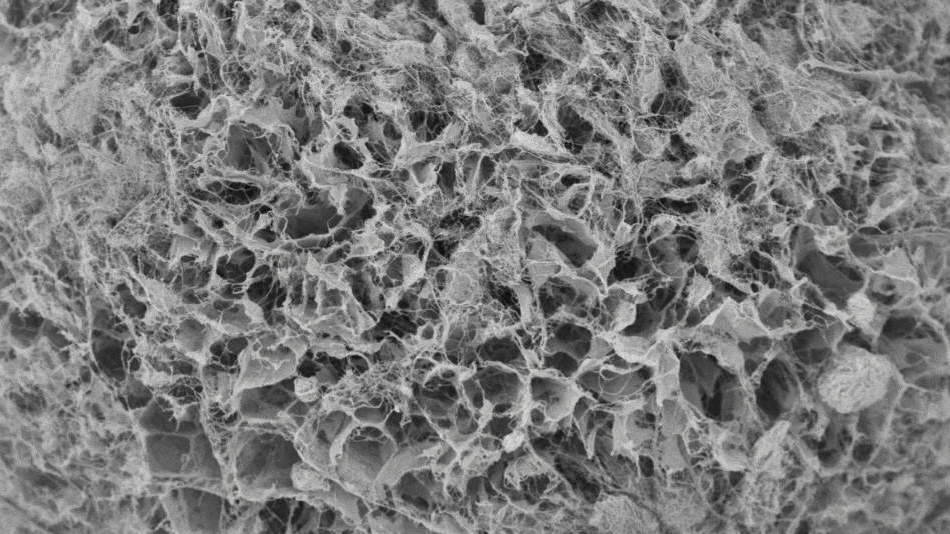

Ultrasonic nozzles are an atomization system that utilizes ultrasonic waves to vibrate the liquid film in order to destabilize and atomize a liquid material. The mechanical vibrations amplified by the ultrasonic oscillator create standing waves in the liquid flow and ripple the liquid film. The liquid film is atomized when the energy of ultrasonic waves exceeds the surface tension. Since liquid is atomized without pressure, there is almost no kinetic energy, resulting in slow and soft atomization. Droplets atomized without pressure are uniform regardless of the flow rate, resulting in a sharp particle size distribution. The droplet size range varies depending on the nozzle type and output, but is generally on the order of tens to hundreds of micrometers.

Summary

Liquid atomization is the most important element in particle design for spray dryers, spray coolers and freeze granulators. Therefore, it is important to determine the right atomization system and operating conditions that can produce the desired granule quality.

- Liquid atomization is important for precise particle formation controls.

- Liquid properties to be controlled include concentration, viscosity, pH, dispersion state, and the properties of primary particles in the case of suspensions or slurries.

- Operating conditions to be controlled include process design shapes, temperature, gas volume, internal pressure, etc.

- Rotary atomization can produce spherical granules with sharp particle size distribution and excellent flowability.

- Pressure nozzles have a simple and robust structure and are often used in mass production plants.

- Two-fluid nozzles can produce fine small particles.

- Ultrasonic nozzles produce droplets without pressure, resulting in a slow and soft atomization.

The table below summarizes the characteristics of each atomization system. *It may vary depending on the usage environment and liquid material characteristics.

| Atomization system | Atomization principle | Droplet diameter | PSD | Sphericity |

| Rotary atomizers | Centrifugal force | 20μm to Several mm | Sharp | ○ |

| Pressure nozzles | Liquid pressure | 30μm to Several mm | Wide | △ |

| Two-fluid nozzles | Gas-liquid mixing | Single to 70μm | Wide | △ |

| Ultrasonic nozzles | Liquid film vibration | Tens to hundreds μm | Wide | △ |

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand under the partnership with T.S.K. Engineering. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements / Contract Powder Processing).