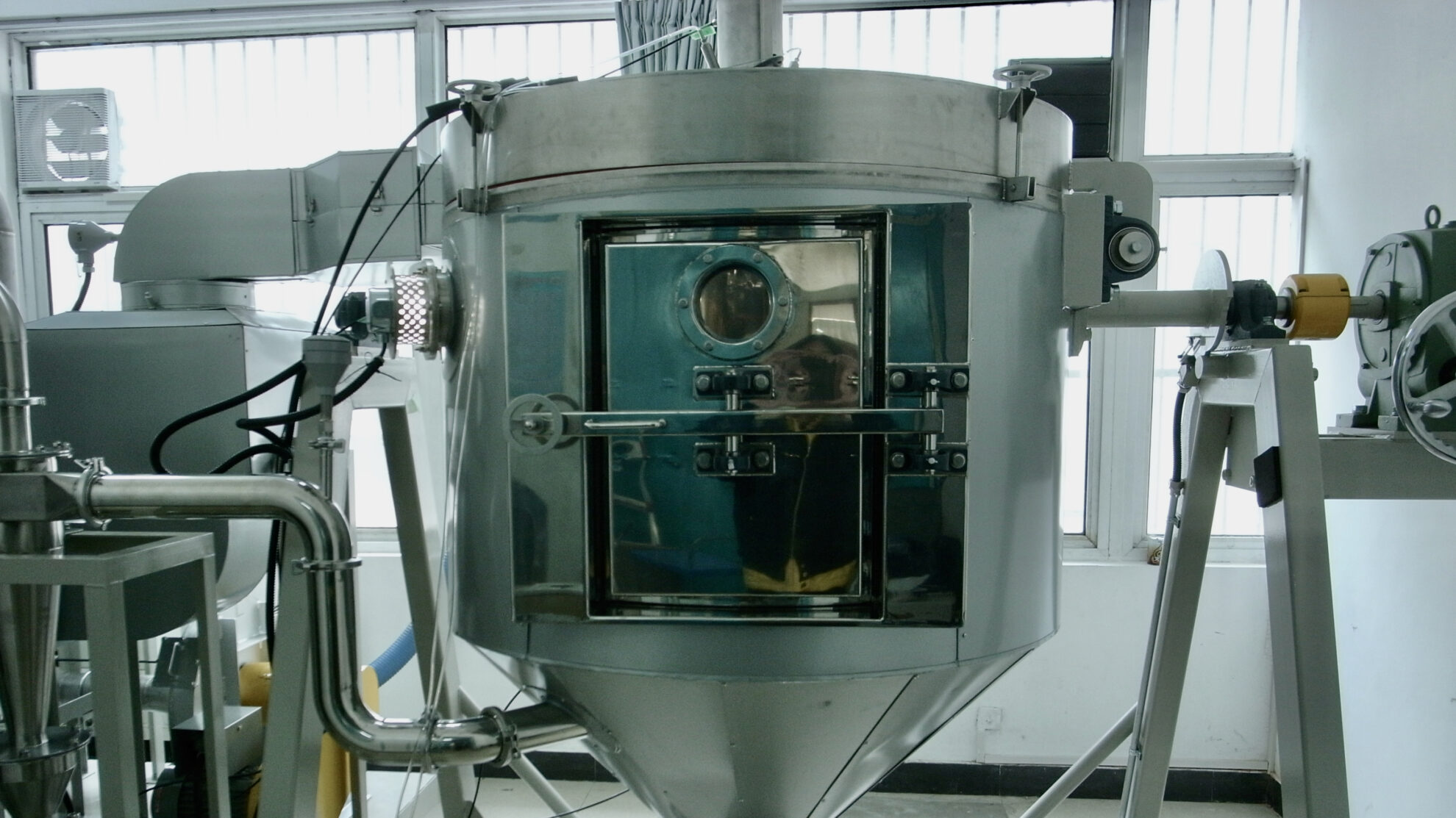

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand under the partnership with T.S.K. Engineering Co., Ltd.. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements.

Characteristics

- Consistent support from R&D to mass production

- One-stop service from powder processing to analytical measurements

- Latest facilities are available without initial investment and maintenance costs

- Time saving by outsourcing operations and analysis

- Obtain new awareness and insights through collaboration with specialized engineers

Services

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

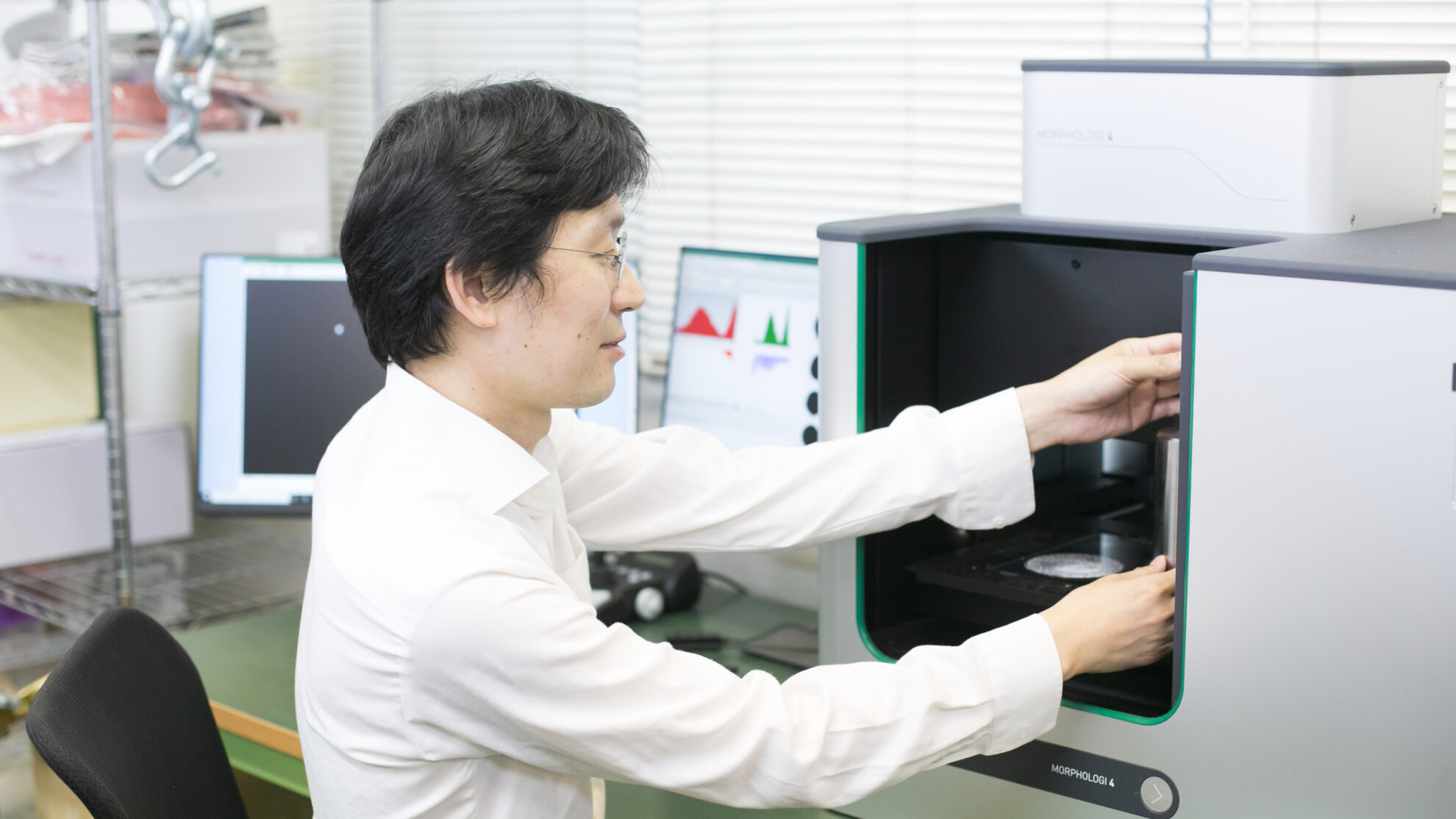

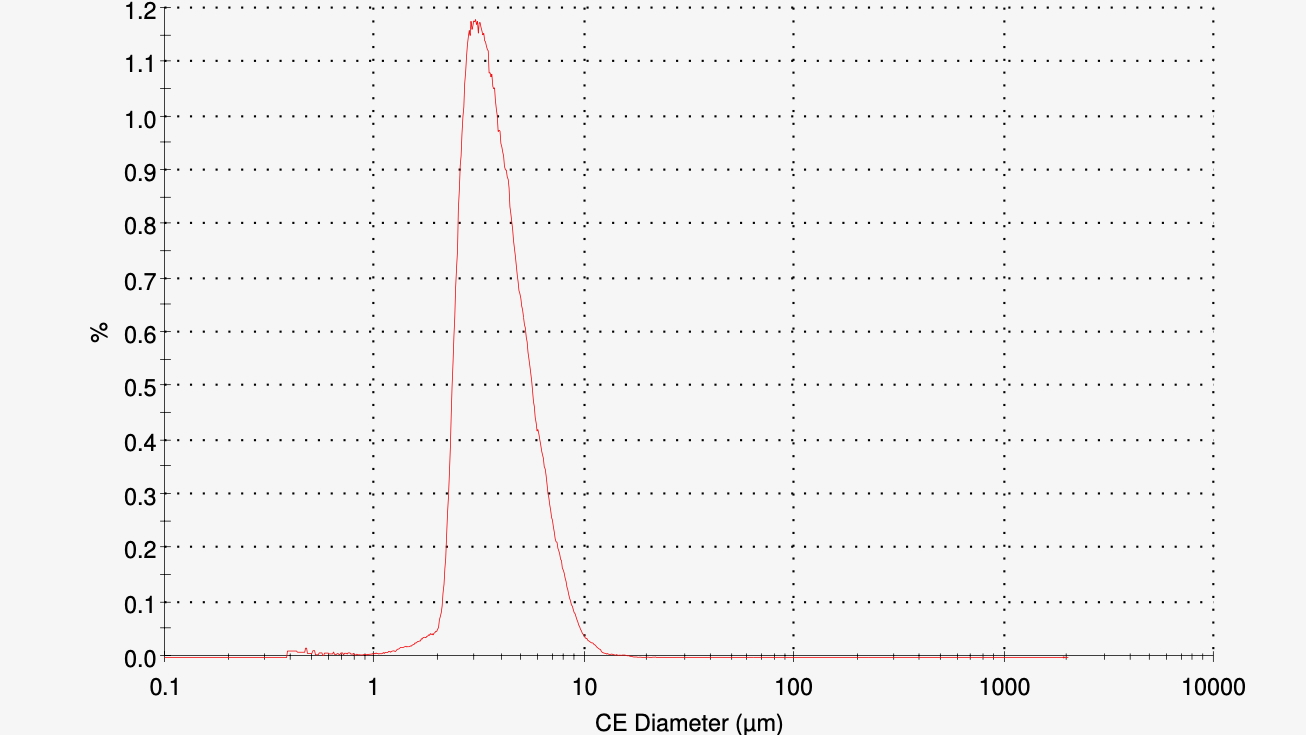

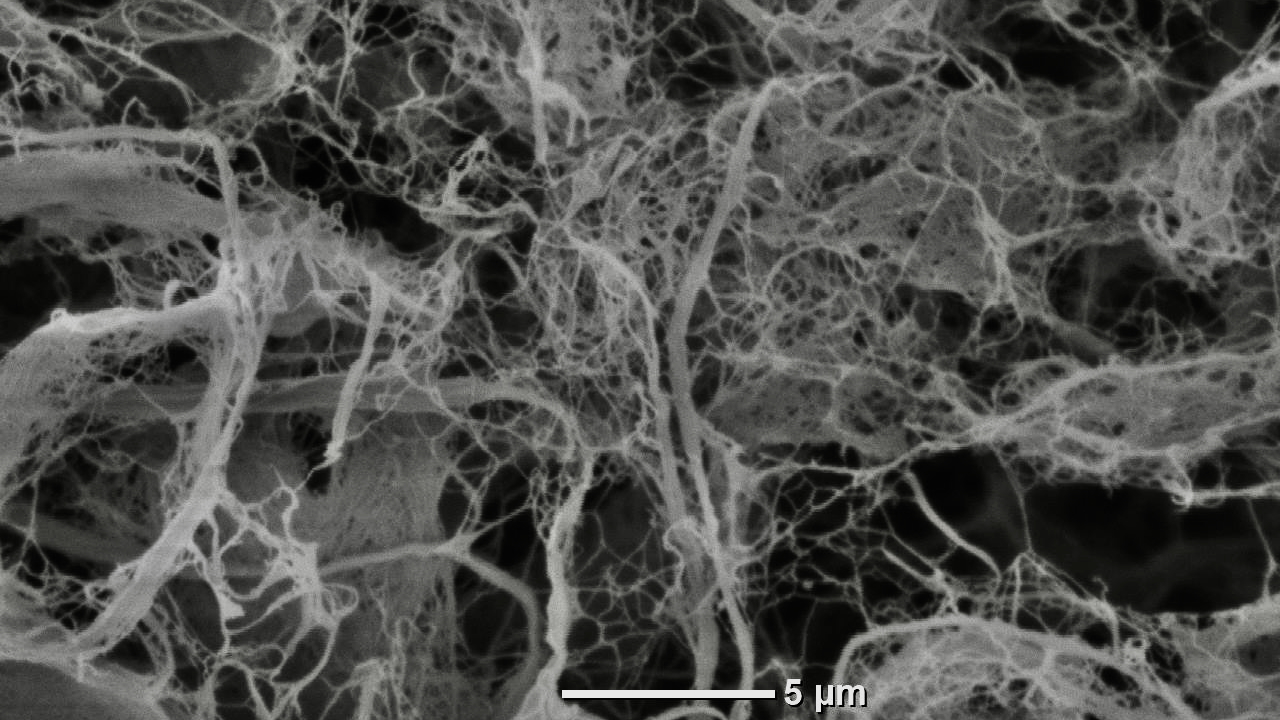

Usage example of analytical measurements

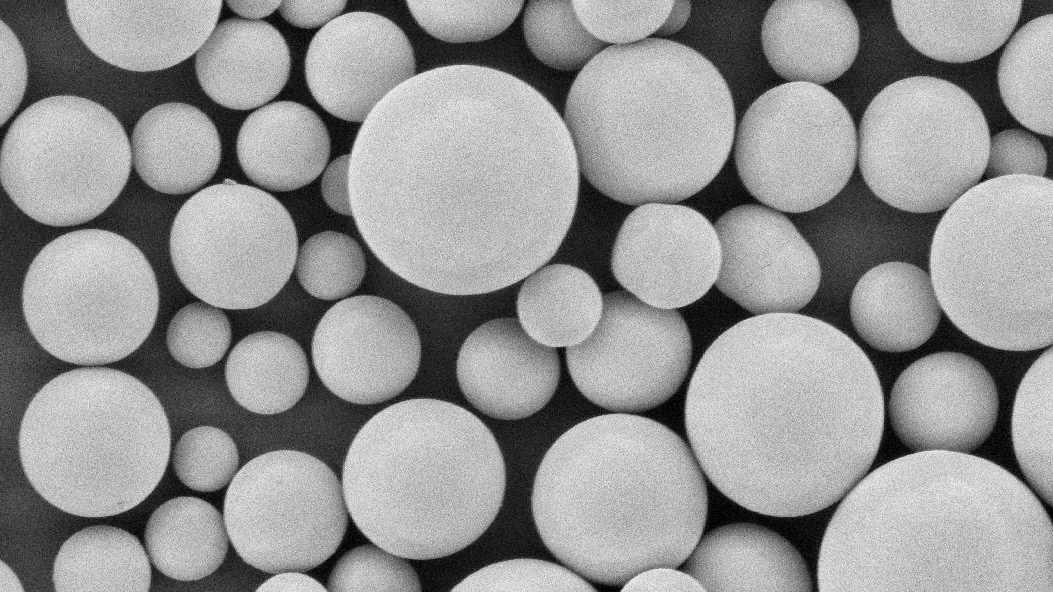

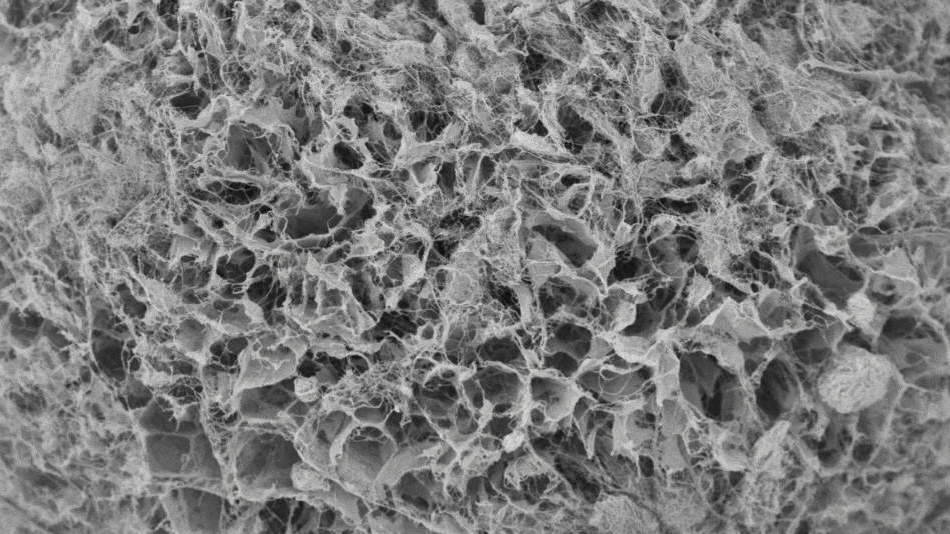

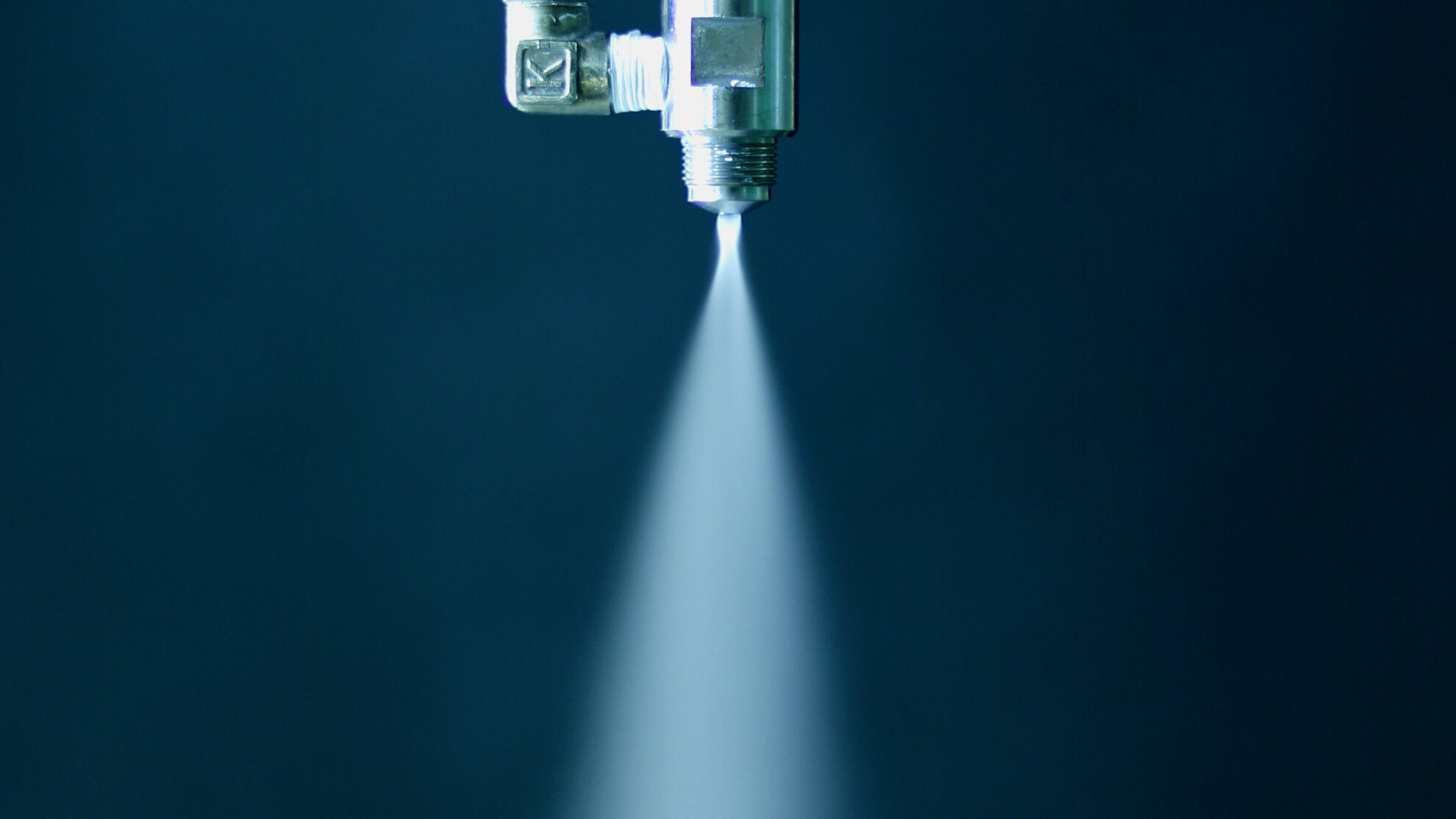

The followings are usage examples of analytical measurements for powder characterization obtained by spray drying, spray cooling, and freeze granulation.

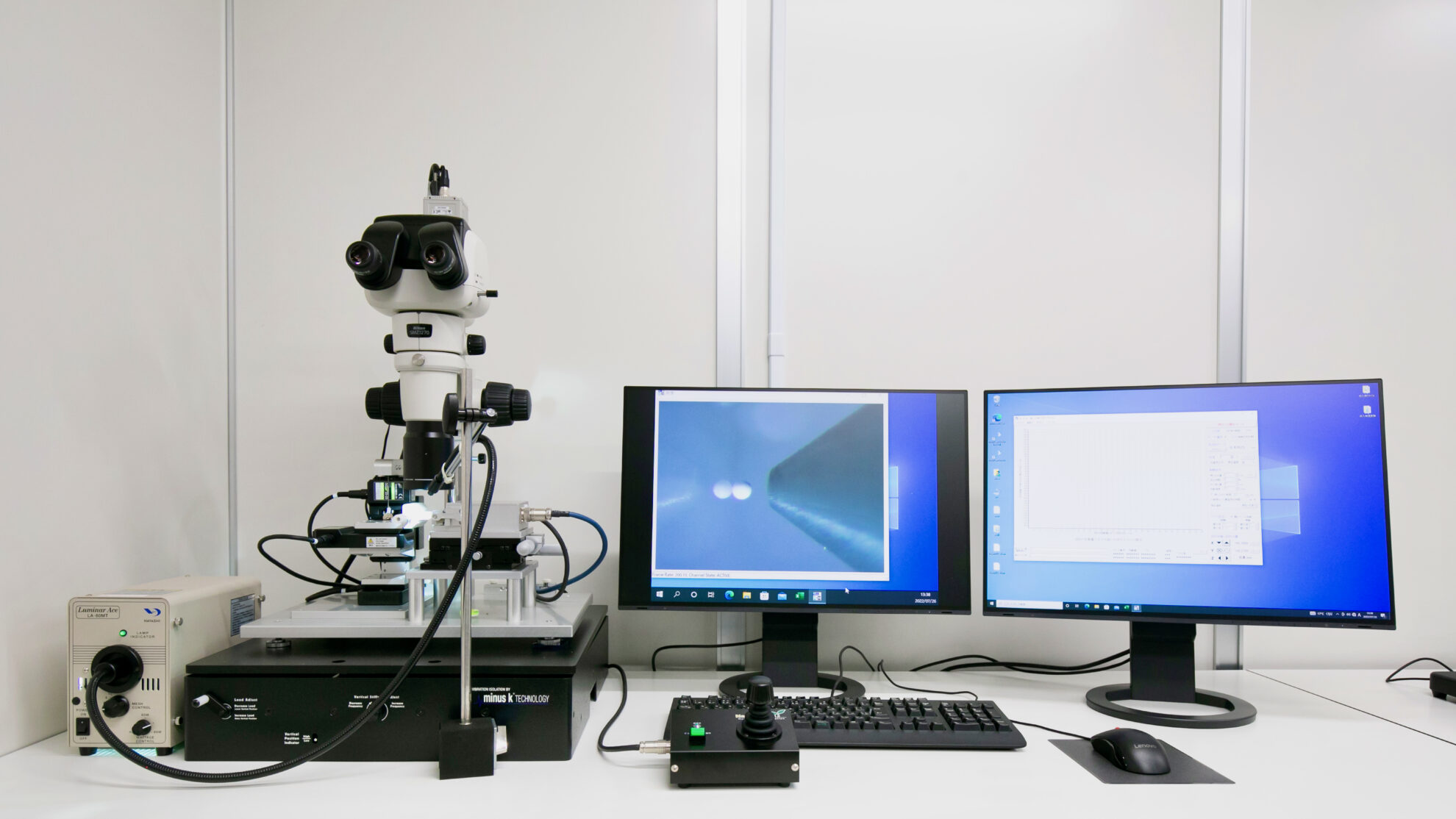

Particle size and shapes of granules are analyzed using multiple image analyzers and laser diffraction analyzers. Imaging analyzers can perform shape analysis such as particle size distribution and circularity, as well as brightness analysis of each individual particle. Online real-time laser diffraction PSD analyzer is also available to perform continuous particle size distribution analysis. SEM analysis can also be used to observe the surface of particles.

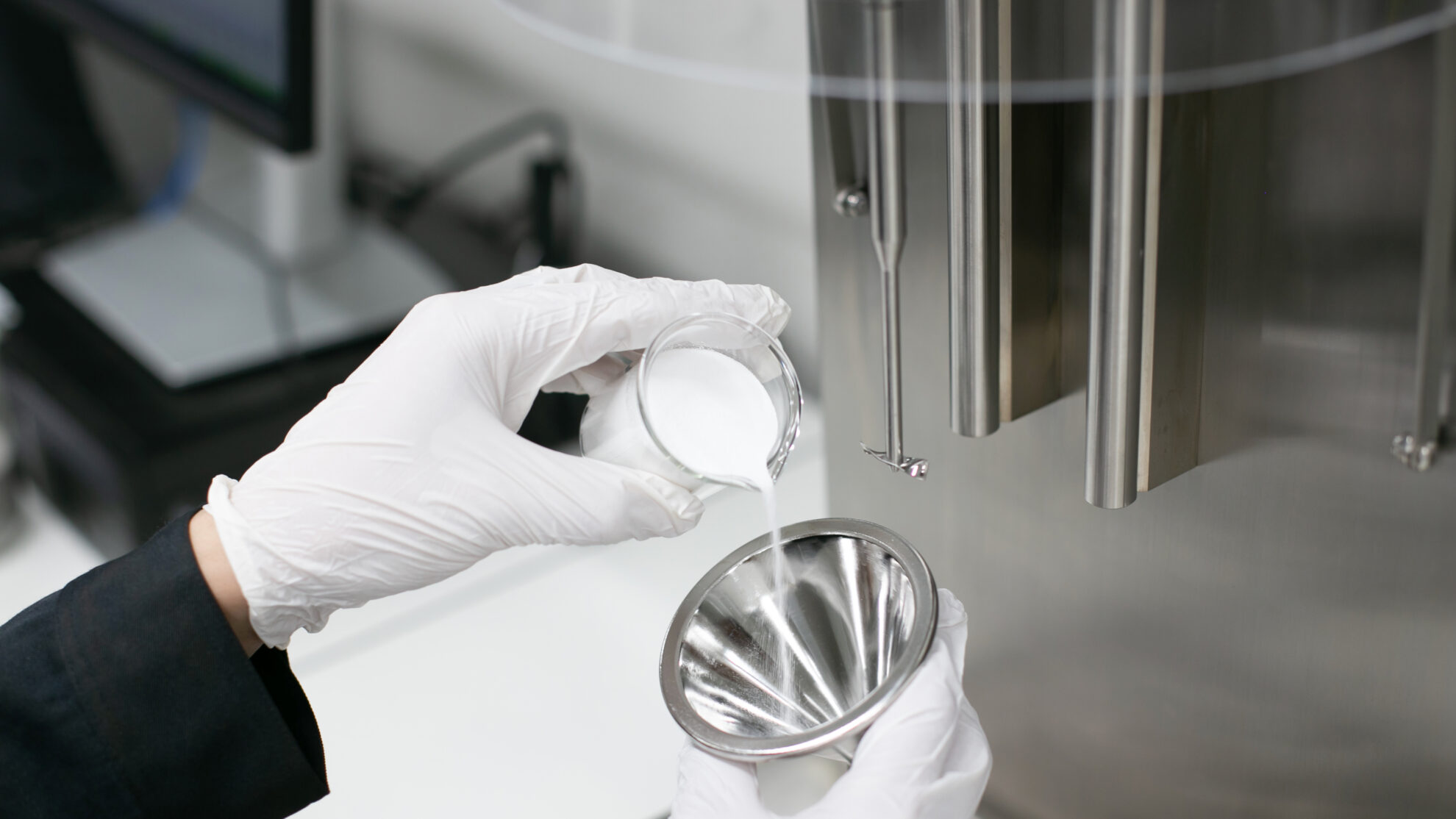

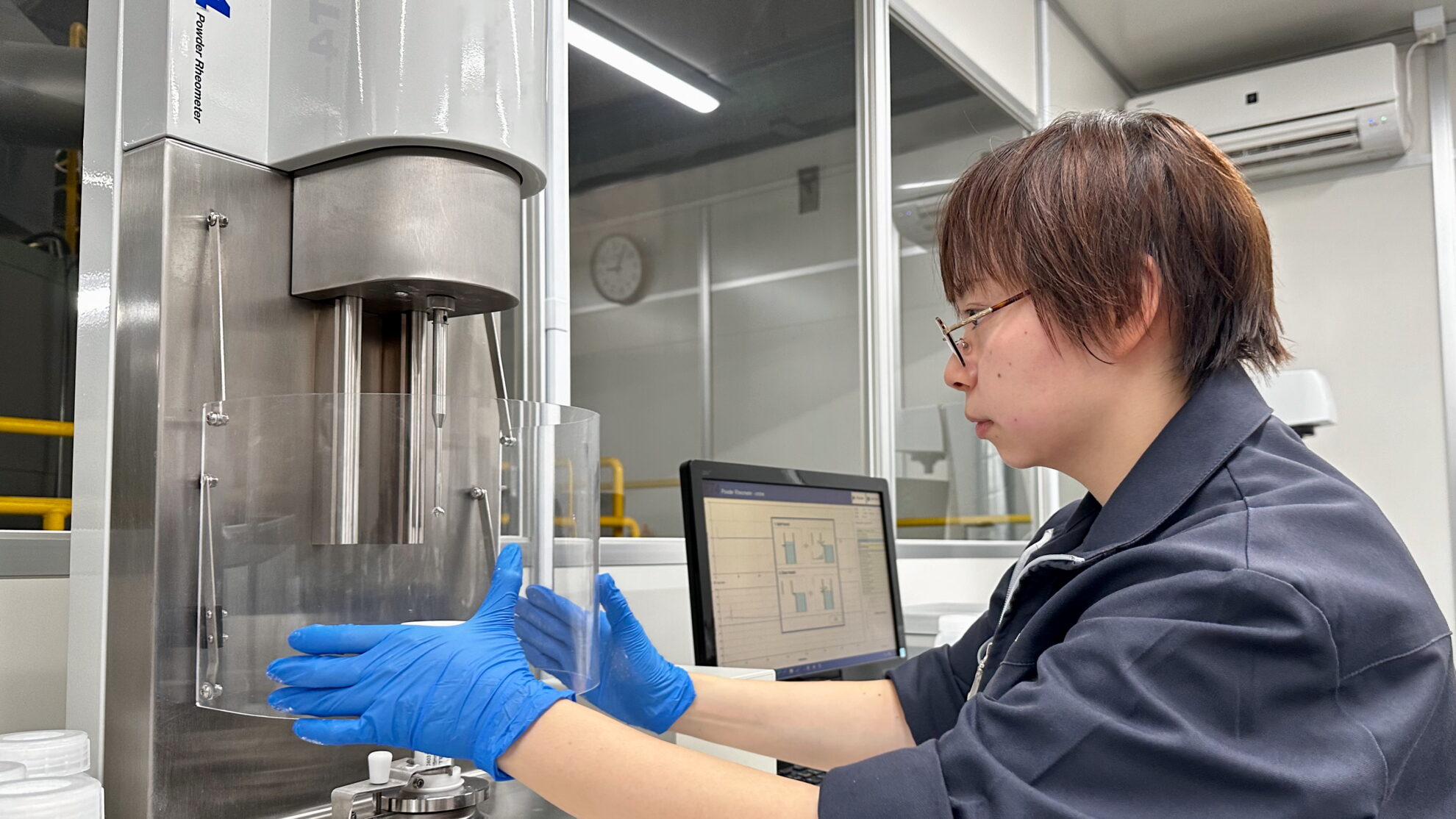

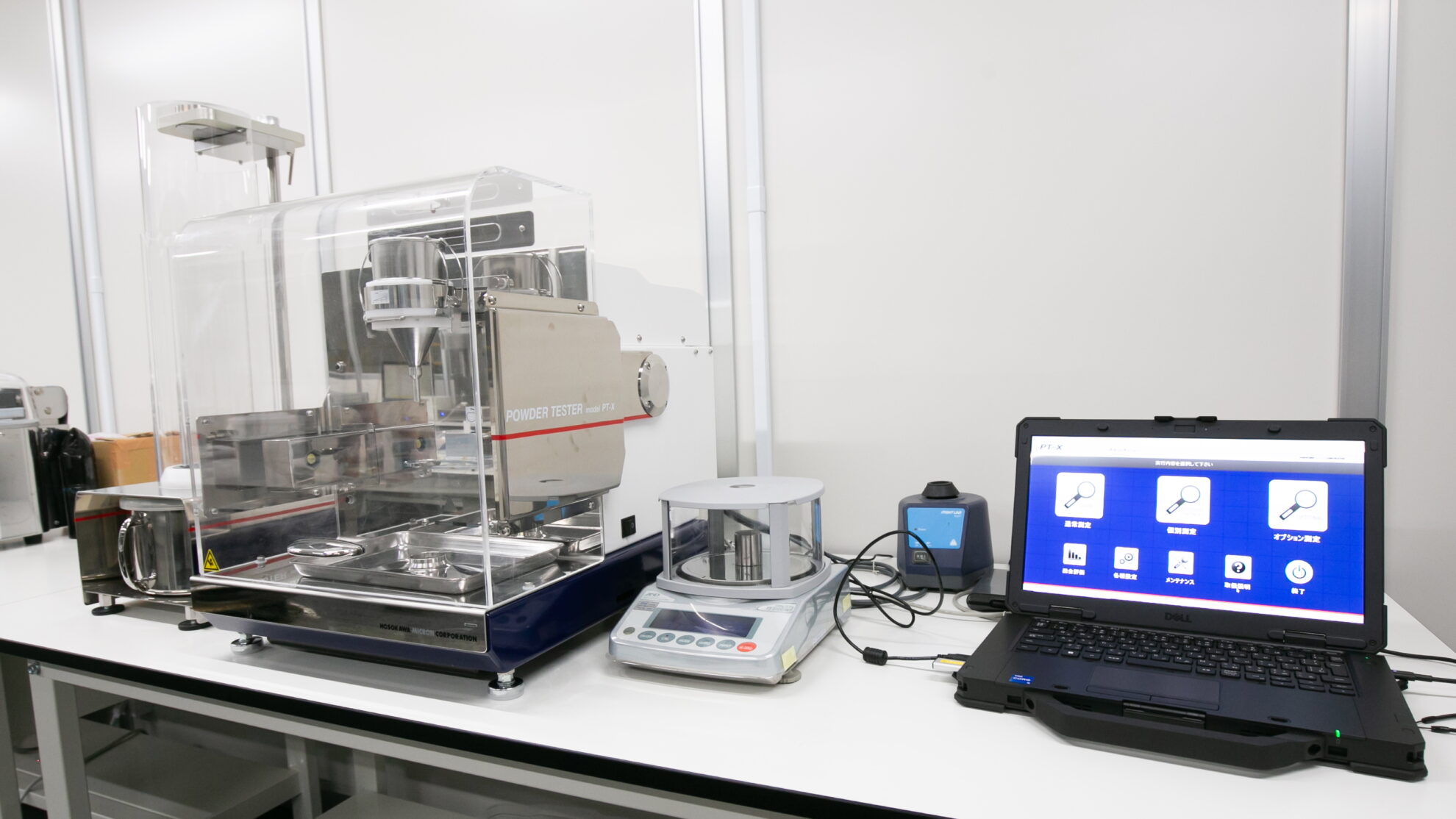

Powder characteristics analyzer and powder rheometer are used to analyze powder fluidity and flowability. In addition to the traditional methods of evaluating fluidity such as angle of repose, bulk density and Carr’s fluidity index, dynamic analysis is also available to measure the actual behavior of powders in a dynamic environment. Dynamic rheometer can also analyze the disintegration properties due to frictions among flowing particles, making it possible to evaluate filling and handling properties of powders.

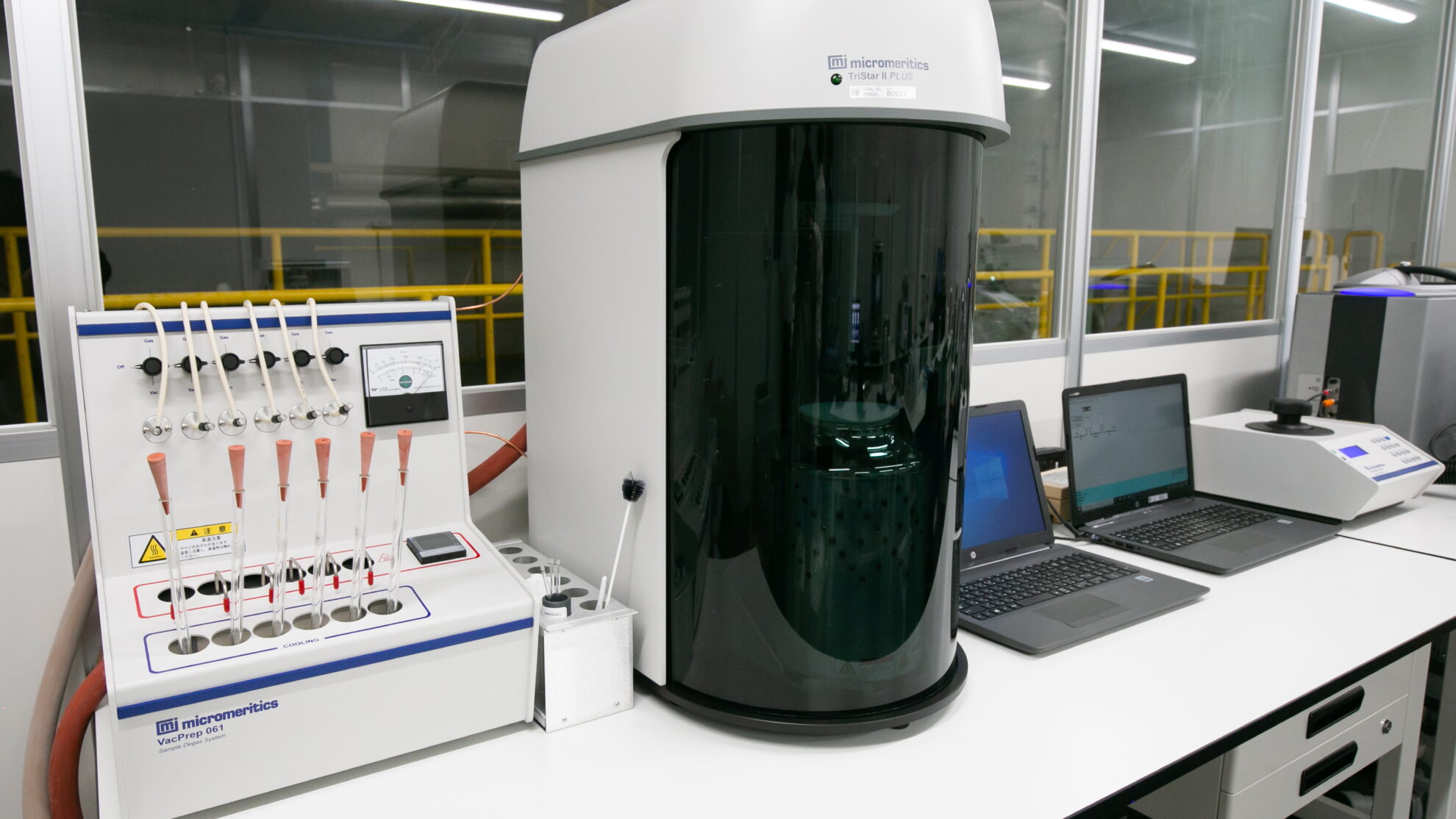

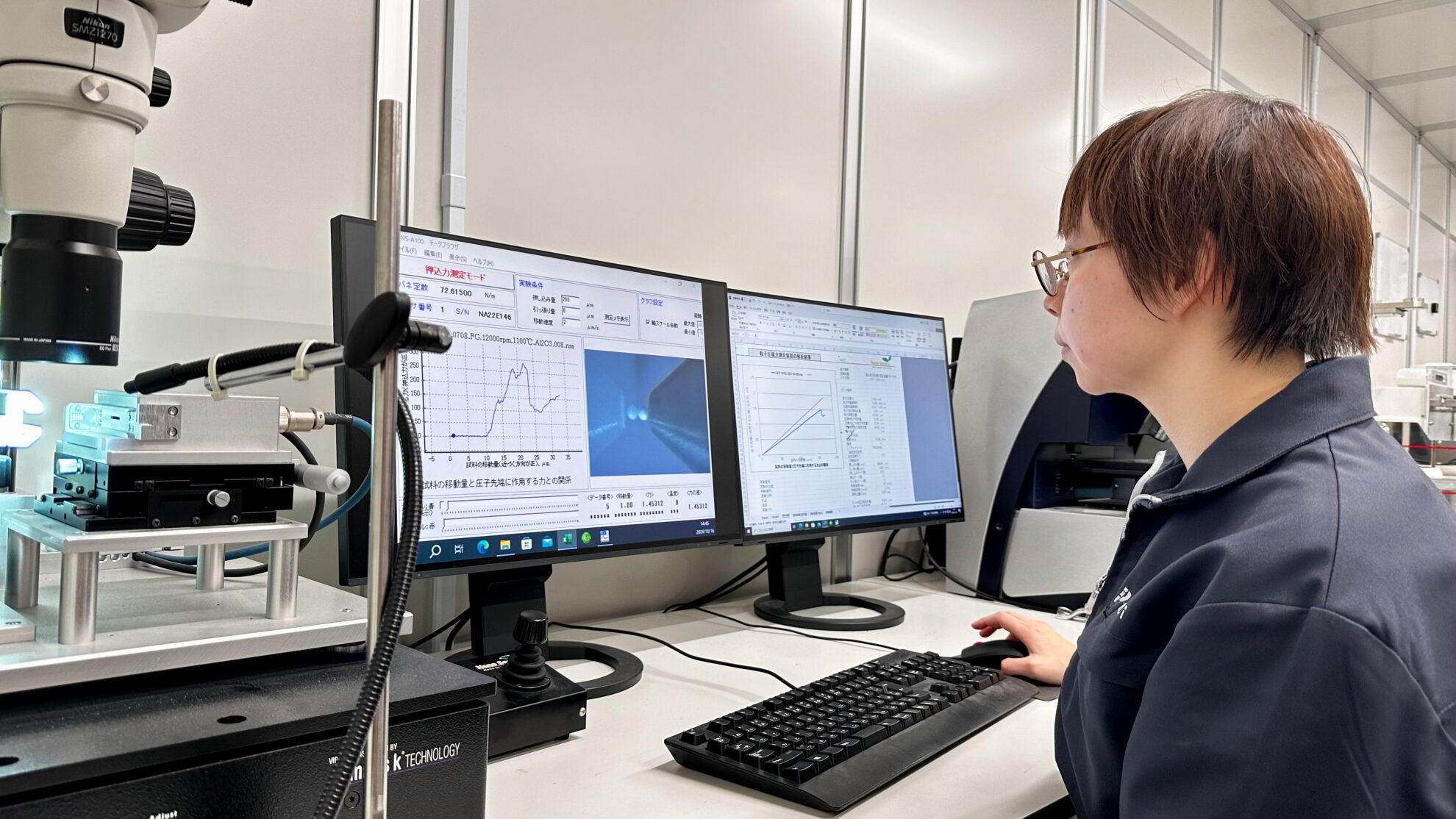

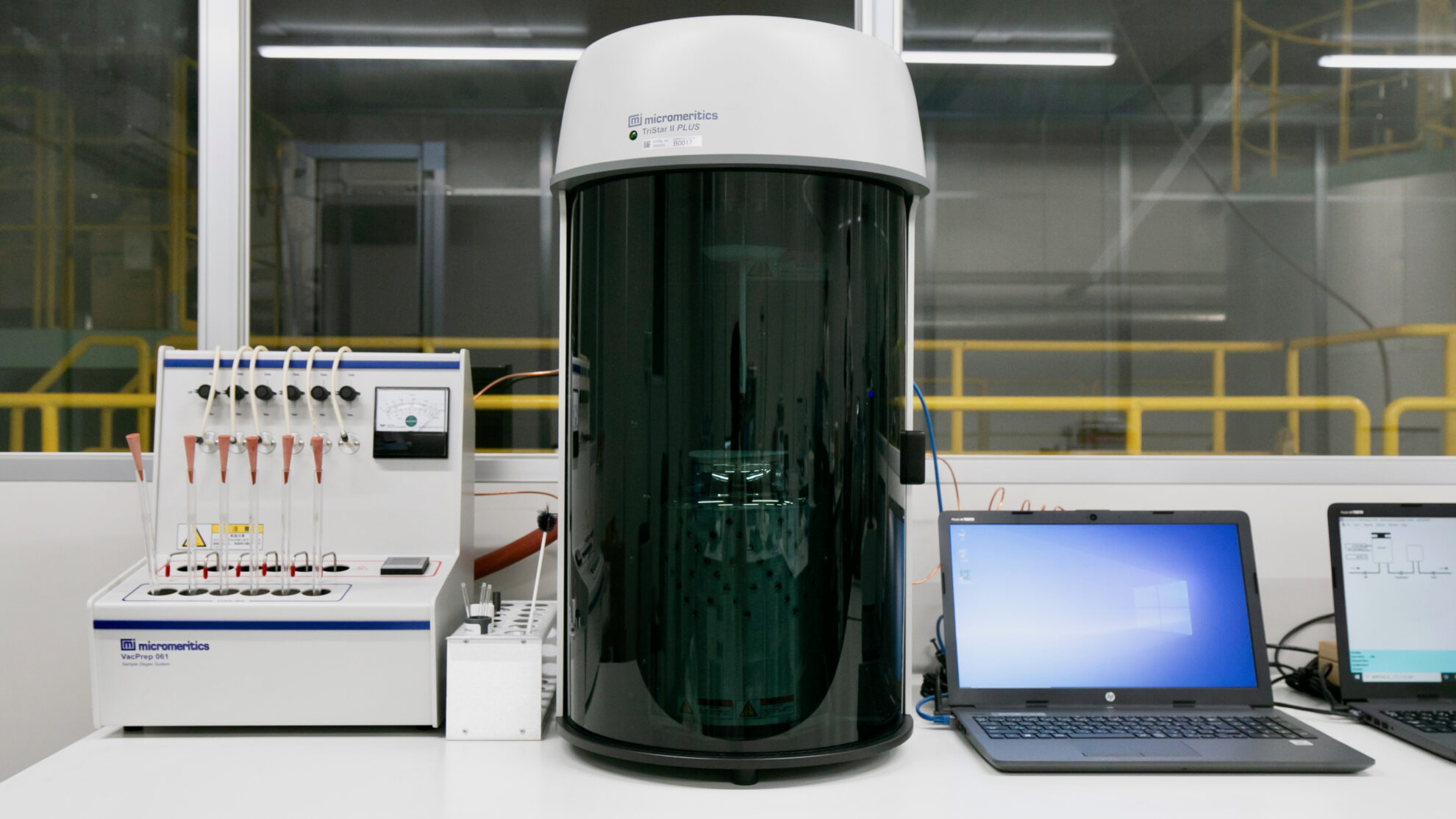

Analysis of specific surface area and density of particles is also important. We measure a specific surface area and pore distribution by constant volume method using gas adsorption. We also analyze true density and particle density by gas displacement method. Micro-particle crushing force measurement is also available to evaluate a particle strength by physically crushing a single particle.

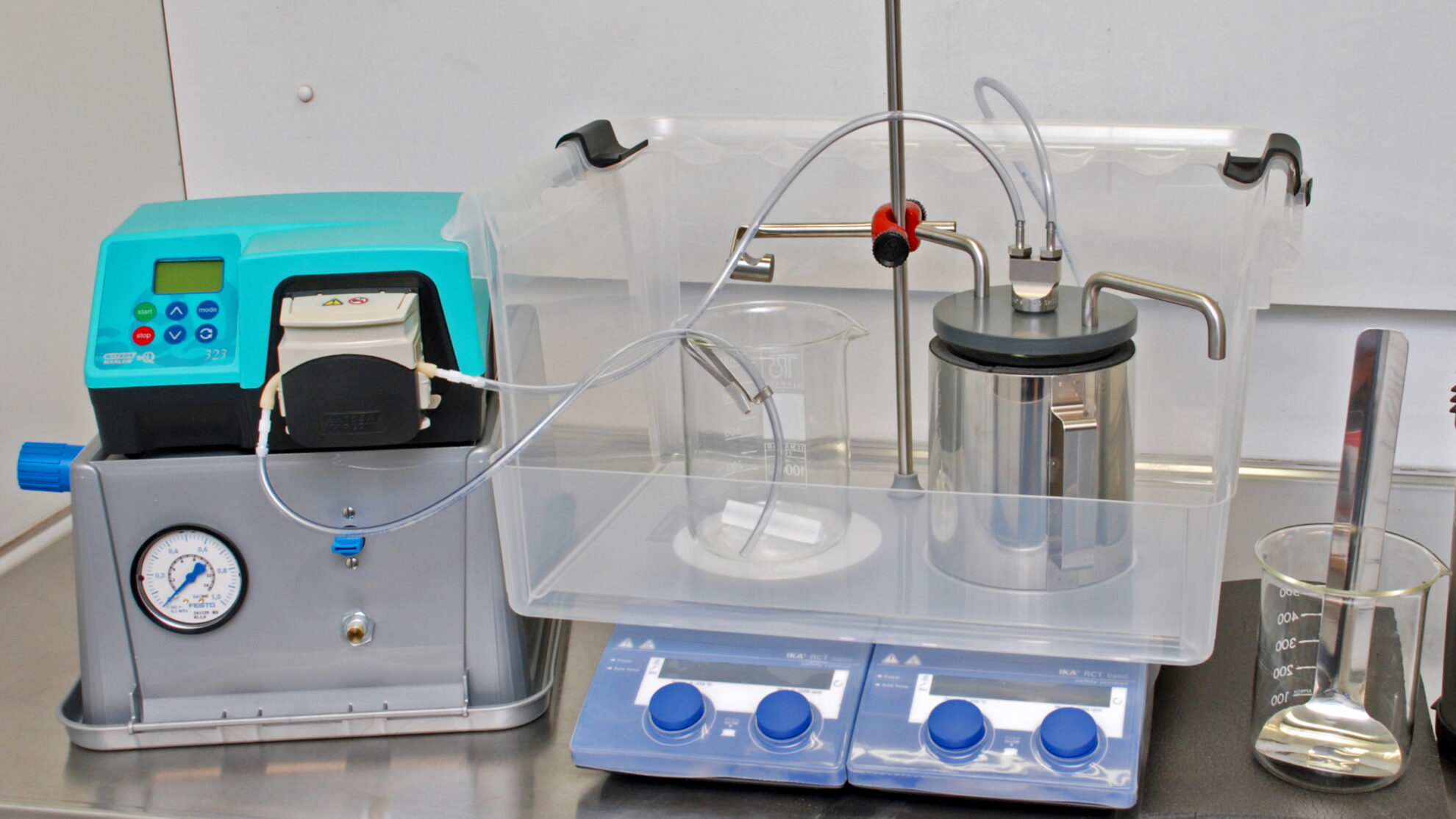

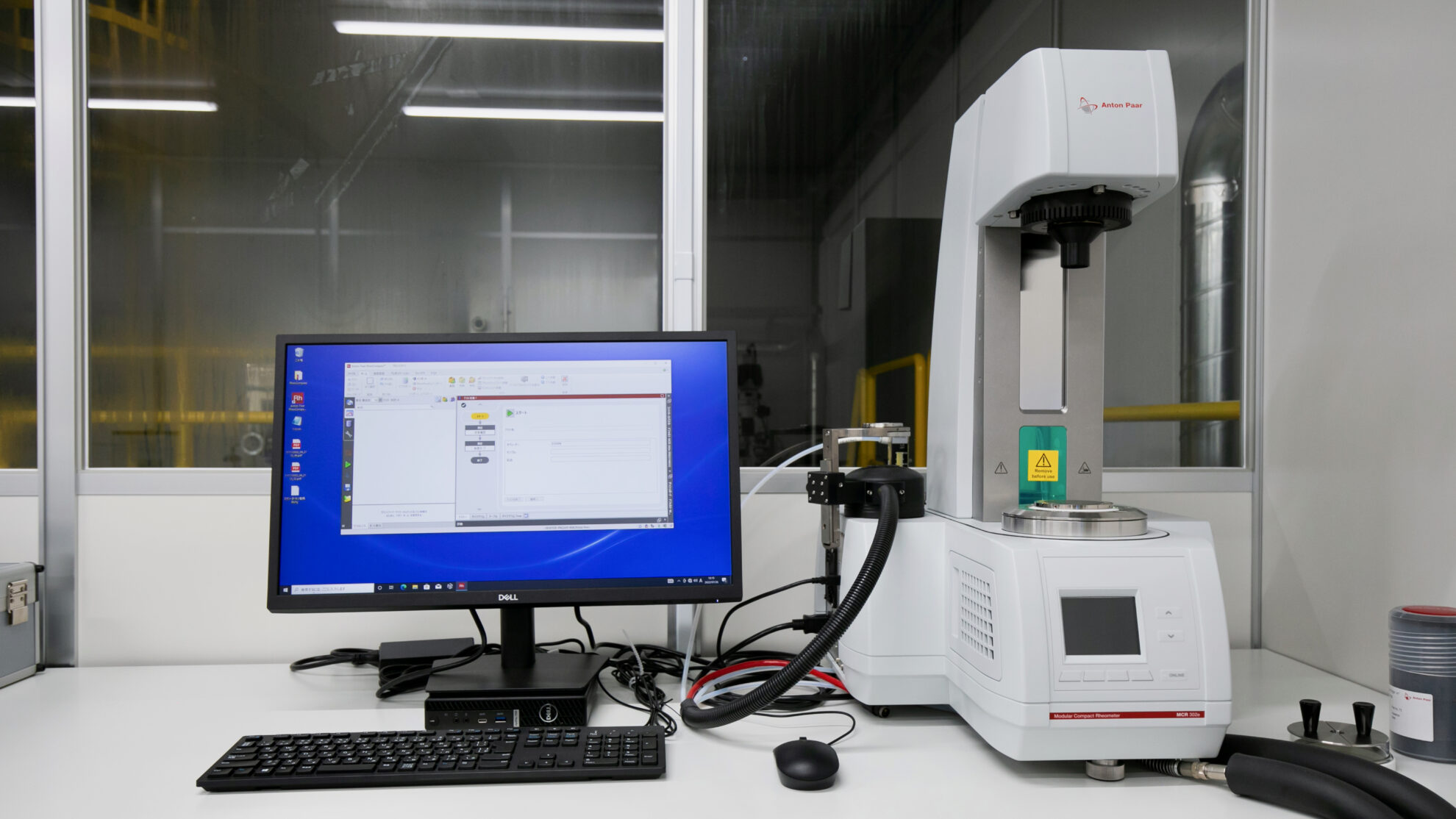

Physical properties of liquid materials are also evaluated for parameters that affect the latter process: powder processing. In the case of slurries or suspensions, primary particle size distribution is measured using laser diffraction analysis. By circulating a liquid material and continuously measuring the particle size distribution, it is also possible to evaluate changes in cohesion, disintegration and re-dispersibility. We also perform rheology analysis using a wet rheometer for dynamic flow behavior such as viscoelasticity, shear stress, cohesive/dispersion stability, thixotropy and dilatancy properties, and yield point.

Facilities

Powder processing

Spray dryers

SB39: 4 units

Chamber diameter: φ387mm

Atomization system: Two-fluid nozzles

Water evaporation vol.: Up to 3kg/h

Note: Closed-cycle system available

TR160: 1 unit

Chamber diameter: φ1600mm

Atomization system: All systems available

Water evaporation vol.: Up to 15kg/h

Note: Closed-cycle system available

P260: 2 units

Chamber diameter: φ2600mm

Atomization system: All systems available

Water evaporation vol.: Up to 30kg/h

D350: 1 unit

Chamber diameter: φ3500mm

Atomization system: All systems available

Water evaporation vol.: Up to 50kg/h

SB39: 1 unit

Chamber diameter: φ387mm

Atomization system: Two-fluid nozzles

Water evaporation vol.: Up to 3kg/h

Note: PTC ASEAN (Thailand)

TR80: 1 unit

Chamber diameter: φ800mm

Atomization system: Rotary atomizers, Two-fluid nozzles

Water evaporation vol.: Up to 3kg/h

Note: PTC ASEAN (Thailand)

P260: 1 unit

Chamber diameter: φ2600mm

Atomization system: All systems available

Water evaporation vol.: Up to 30kg/h

Note: PTC ASEAN (Thailand)

Spray coolers

Spray cooling processing is available using the above spray dryers.

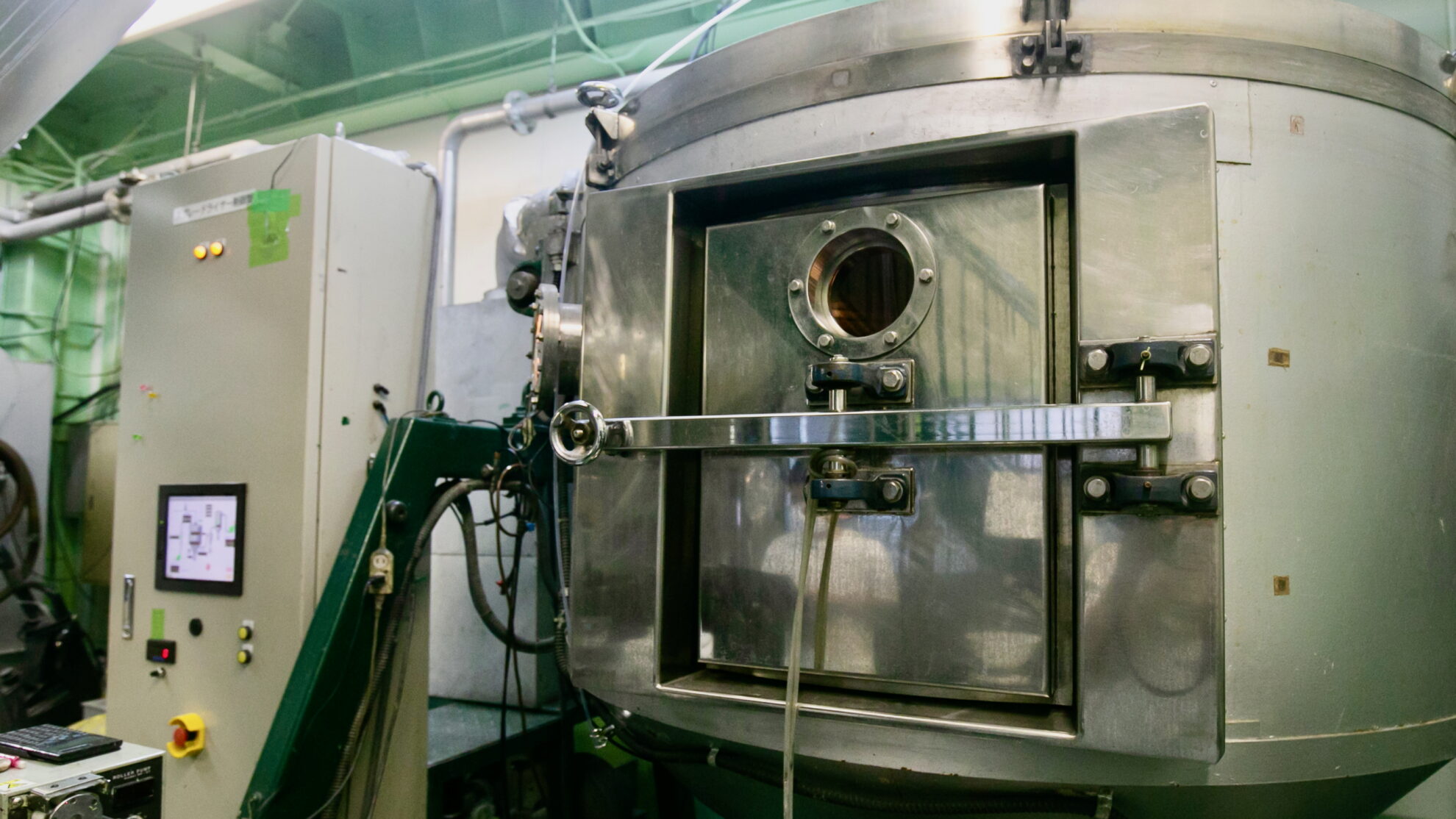

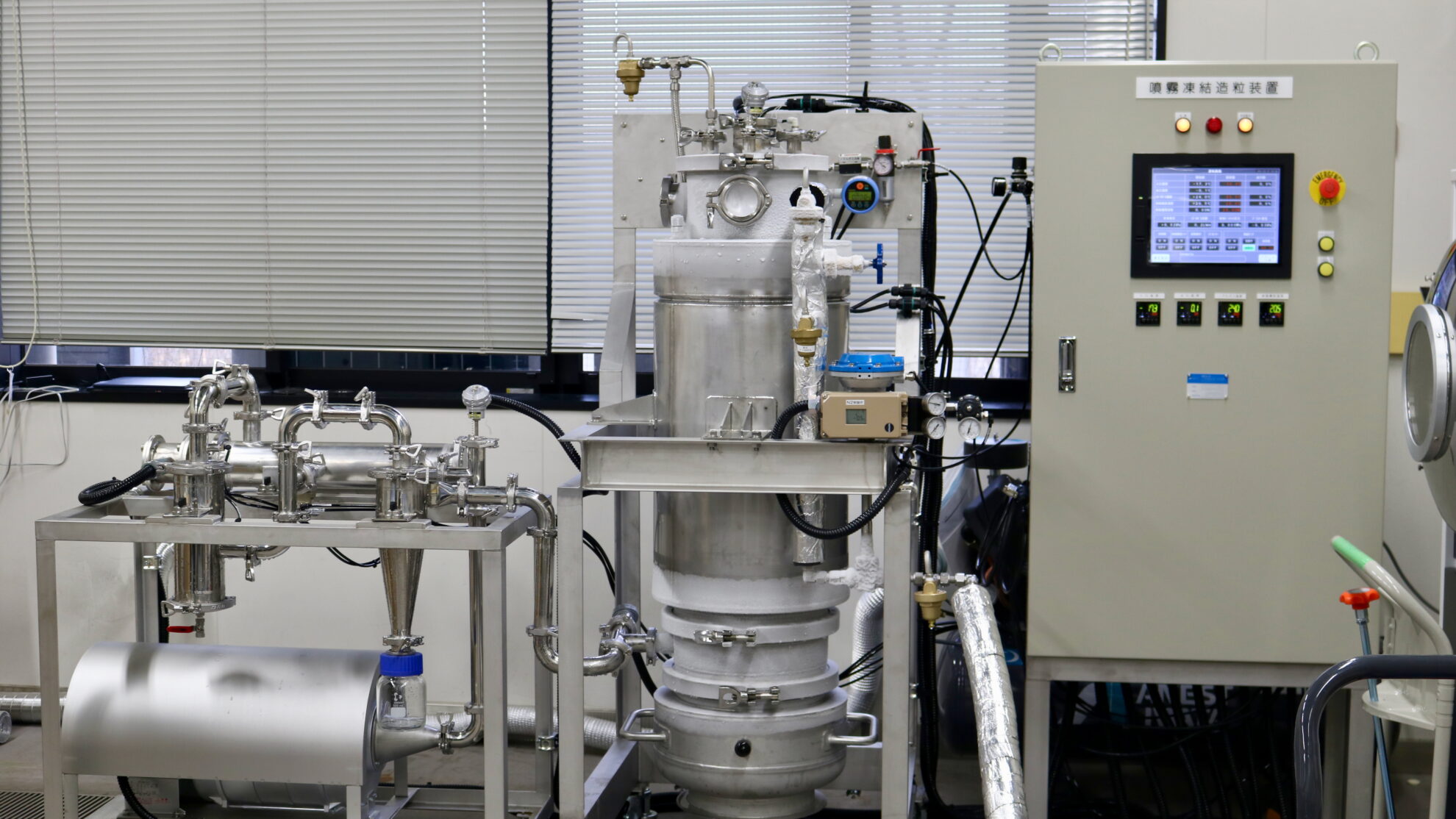

Freeze granulators

LS-6: 1 unit

Container diameter: φ120mm

Atomization system: Two-fluid nozzles

Material feed capacity: Up to 6kg/h

Cooling temperature: −196℃

Cooling system: Wet cooling system

CS30: 1 unit

Chamber diameter: φ300mm

Atomization system: Two-fluid nozzles

Material feed capacity: Up to 15kg/h

Cooling temperature: −10 ~ −120℃

Cooling system: Dry cooling system

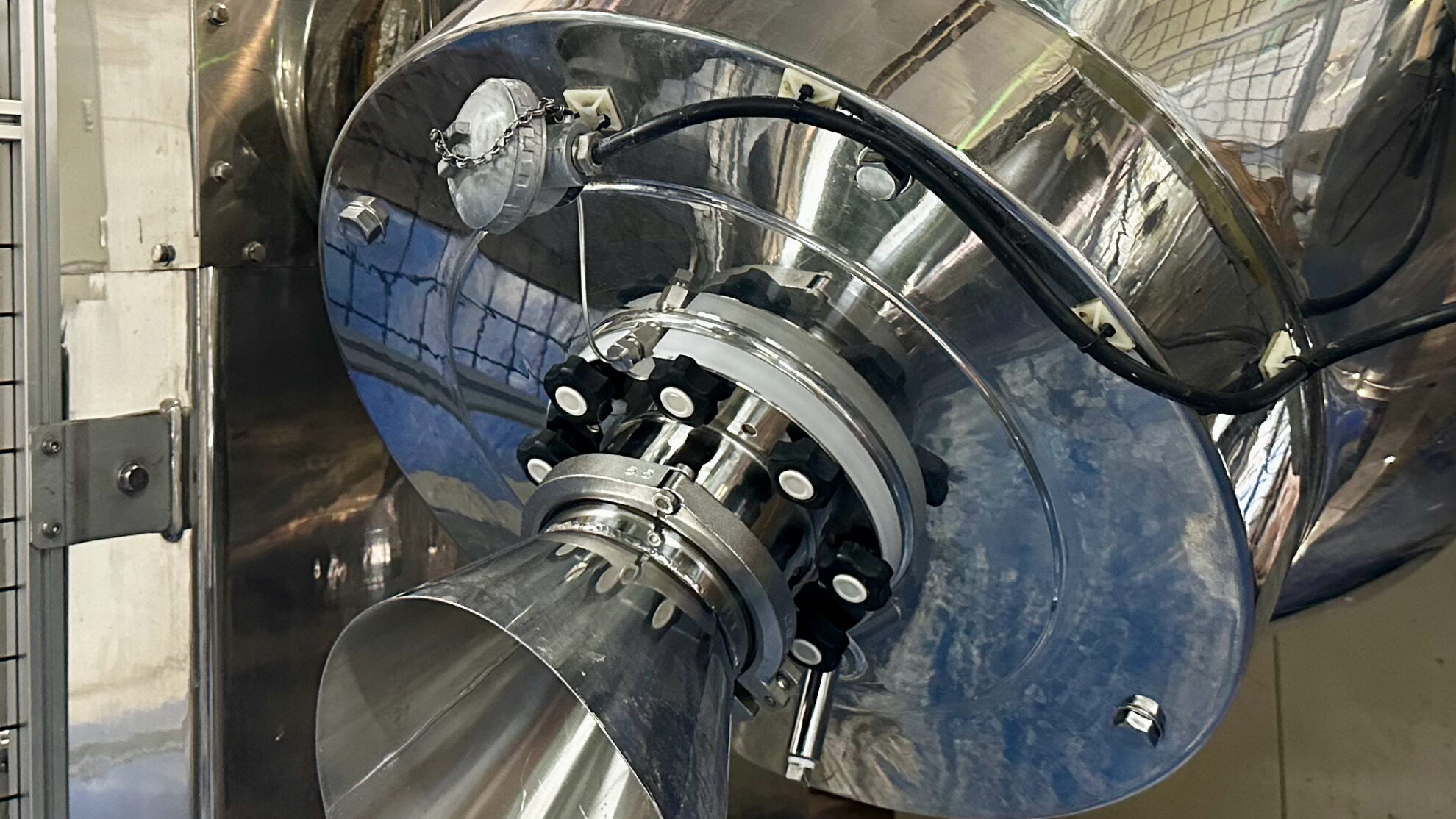

CS220: 1 unit

Chamber diameter: φ2200mm

Atomization system: All systems available

Material feed capacity: Up to 320kg/h

Cooling temperature: −10 ~ −50℃

Cooling system: Dry cooling system

Freeze dryers

FDU-2110: 1 unit

Tray volume: 700ml × 6 stages

Cold trap capacity: 3kg

Cold trap temperature: −80℃

FD-551: 1 unit

Tray volume: 8000ml × 3 stages

Cold trap capacity: 10kg

Cold trap temperature: −45℃

TFD-10: 1 unit

Chamber volume: 85L

Cold trap capacity: 10kg

Cold trap temperature: −40℃

RHEOFREED: 1 unit

Chamber volume: 160L

Cold trap capacity: 30kg

Cold trap temperature: −45℃

Liquid processing & Wet grinding

POT MILL: 4 units

Note: Various capacities available

BALL MILL (50L): 2 units

Container capacity: 50L

Material contact part: Nylon

Balls: Zirconia φ10mm

BALL MILL (100L): 2 units

Container capacity: 100L

Material contact part: Nylon

Balls: Zirconia φ10mm

BEAD MILL: 1 unit

Model: RMH-08

Vessel capacity: 0.95L

Material contact part: Zirconia

Beads: Zirconia φ0.5 or 1.0mm

Molding & Sintering

UNIAXIAL MOLDING MACHINE: 1 unit

Model: SMT-200AF

Pressure capacity: Max. 200kN

Note: CIP container available

MUFFLE FURNACE: 1 unit

Model: FP103

Temperature range: 100 to 1150℃

Inner dimensions: 100 x 150 x 100mm

Note: Nitrogen available

HORIZONTAL TUBULAR FURNACE: 1 unit

Model: HF1800

Temperature range: 300 to 1800℃

Chamber: Al2O3 tube φ60mm

Note: Vacuum and nitrogen available

Analytical measurements

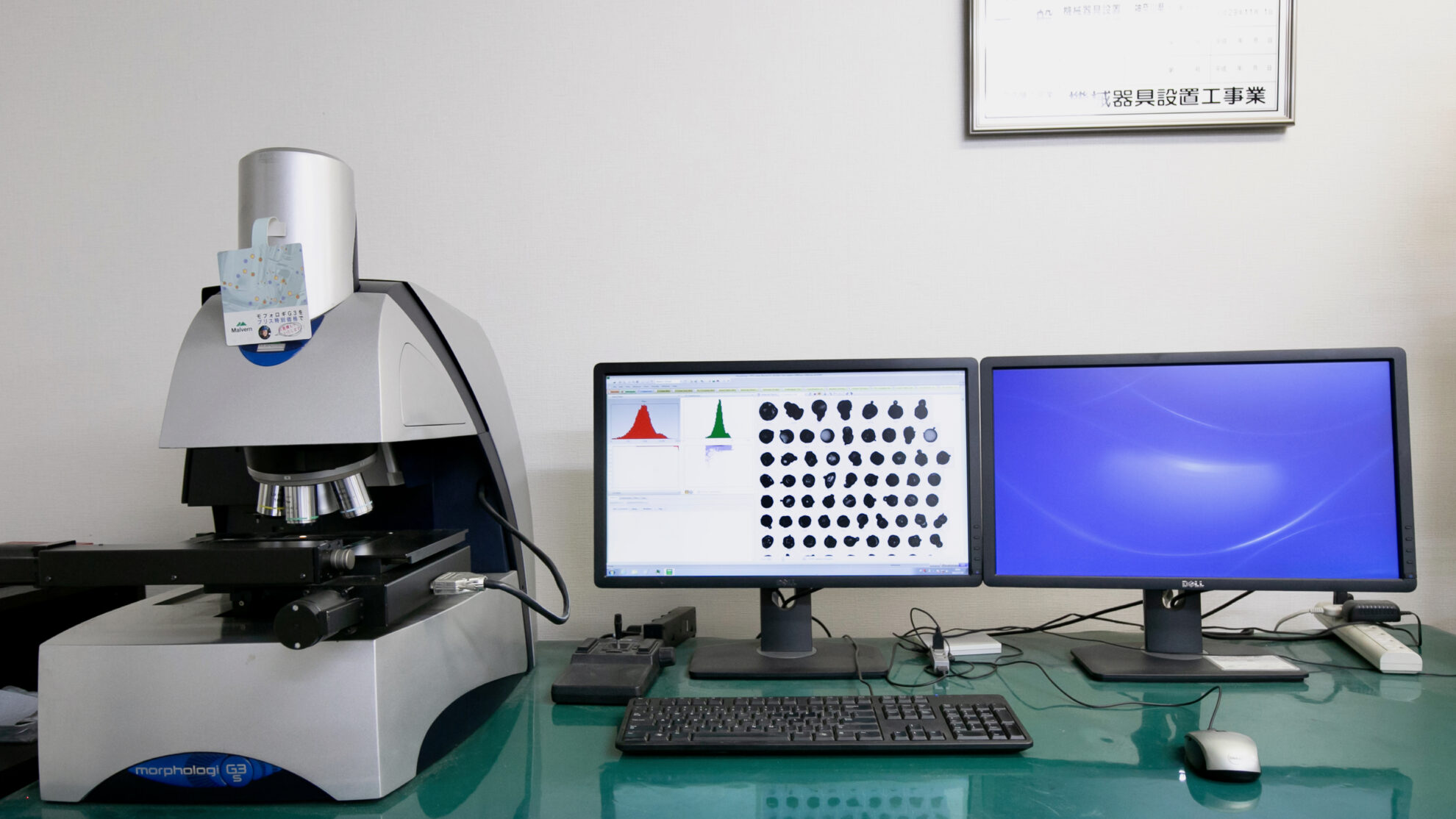

PSD ANALYZER: 1 unit

Model: Morphologi G3

Measurement items: Particle size, shape, PSD, etc.

Note: Image-based analysis

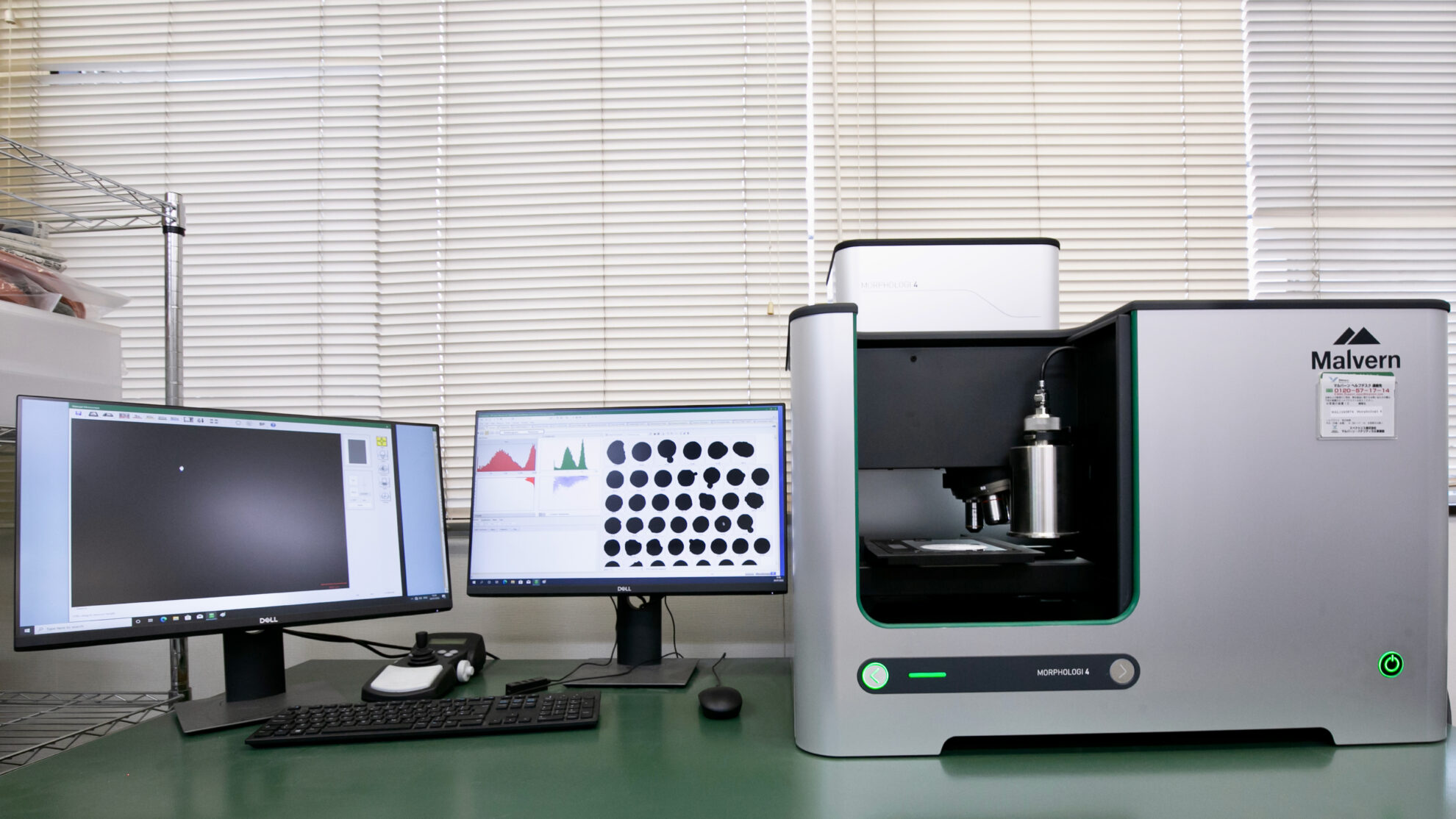

PSD ANALYZER: 1 unit

Model: Morphologi 4

Measurement items: Particle size, shape, PSD, etc.

Note: Image-based analysis

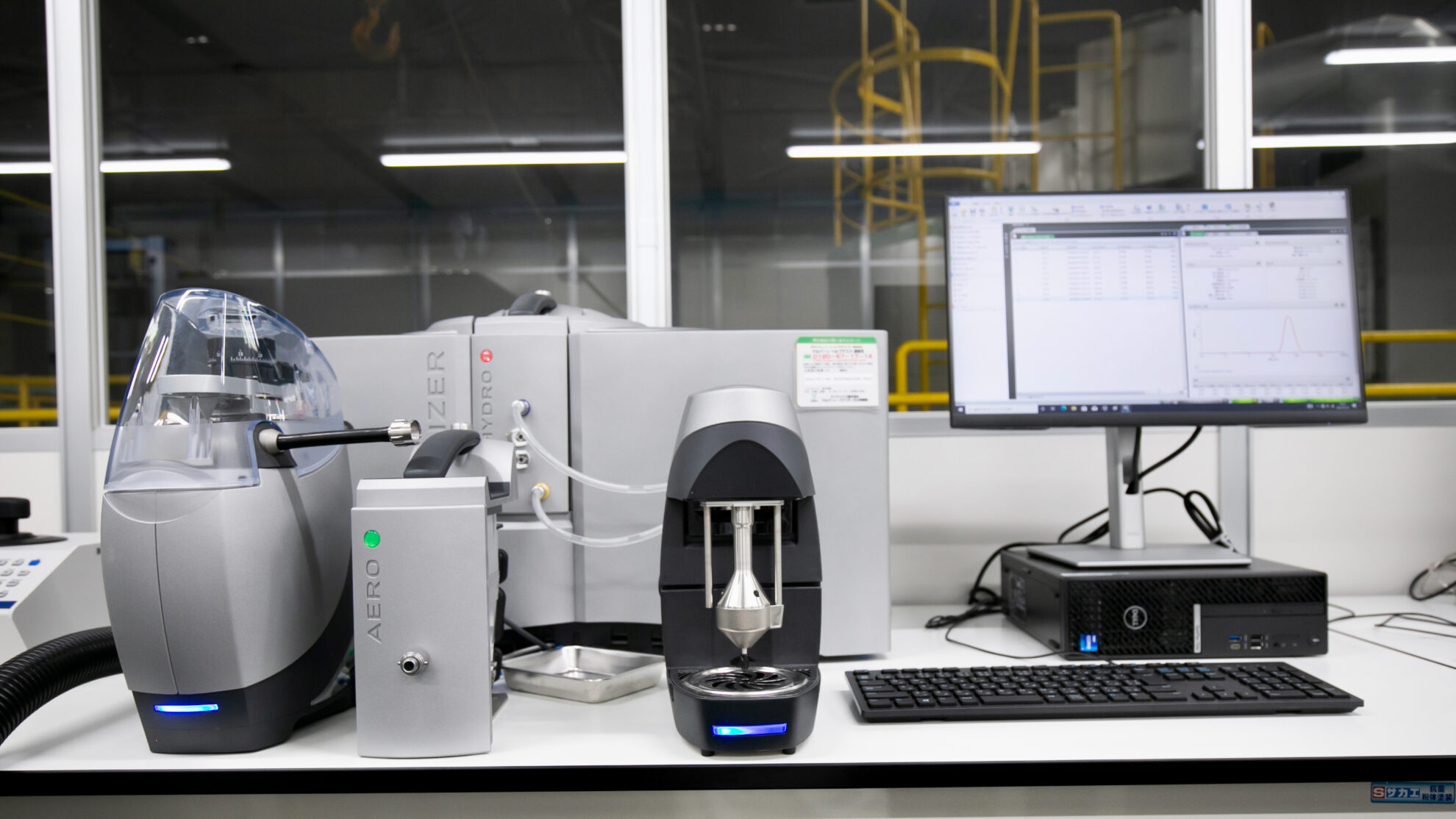

PSD ANALYZER: 1 unit

Model: Mastersizer 3000

Measurement items: Particle size, PSD

Note: Laser diffraction analysis

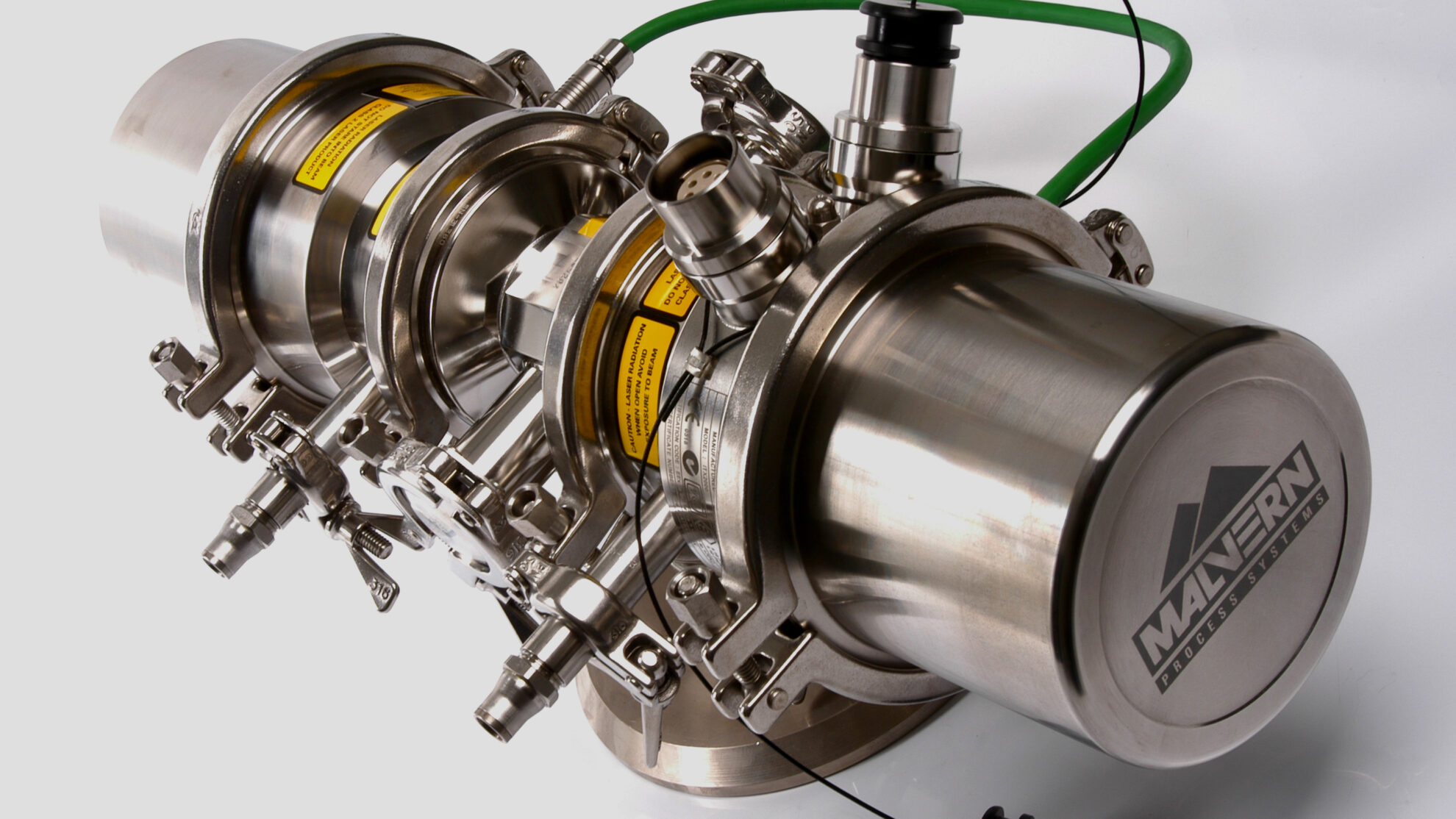

REAL-TIME PSD ANALYZER: 1 unit

Model: Insitec

Measurement items: Particle size, PSD

Note: Laser diffraction analysis

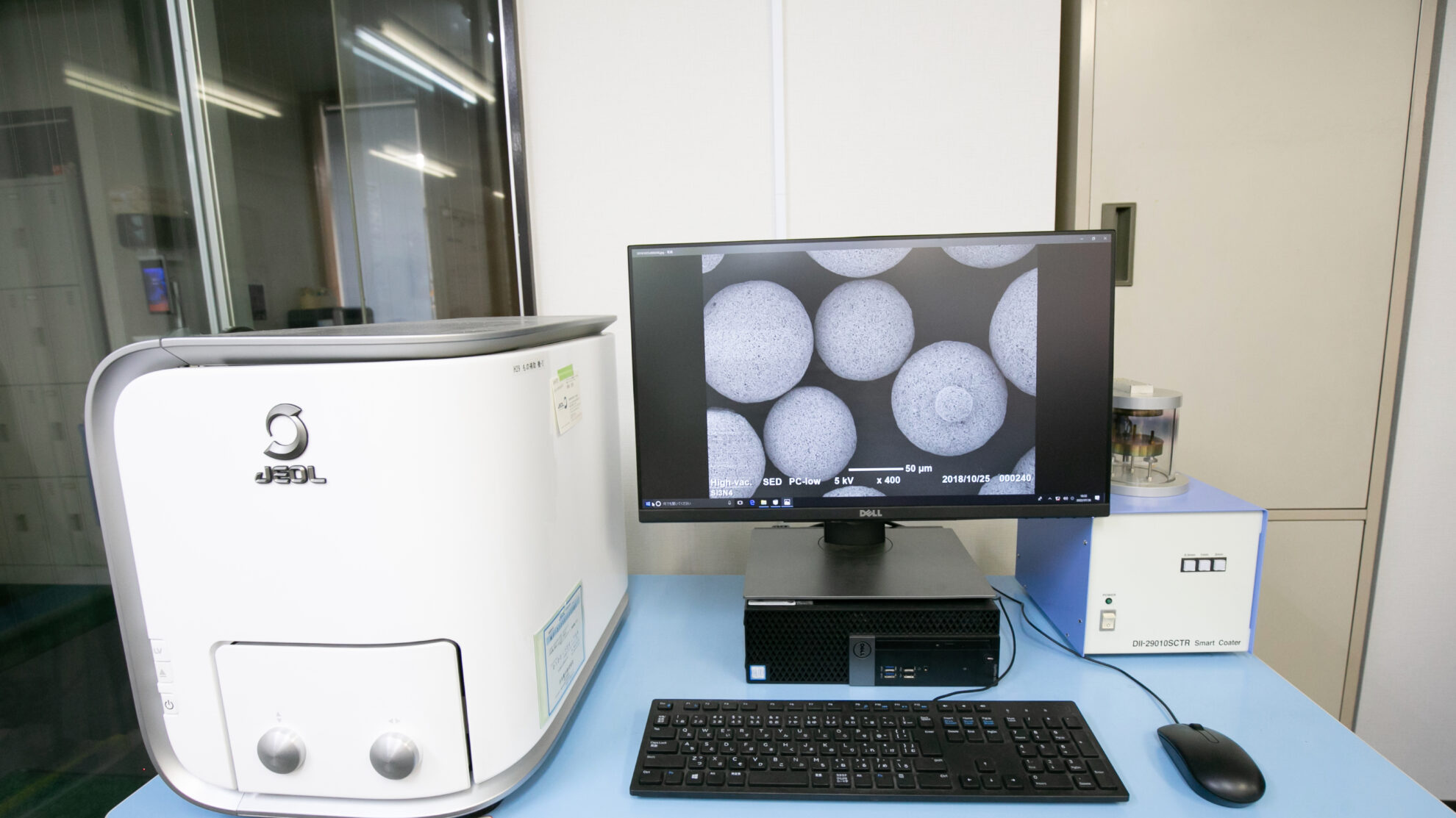

SEM: 1 unit

Model: JCM-6000Plus

Measurement items: Shape, structure, surface, etc.

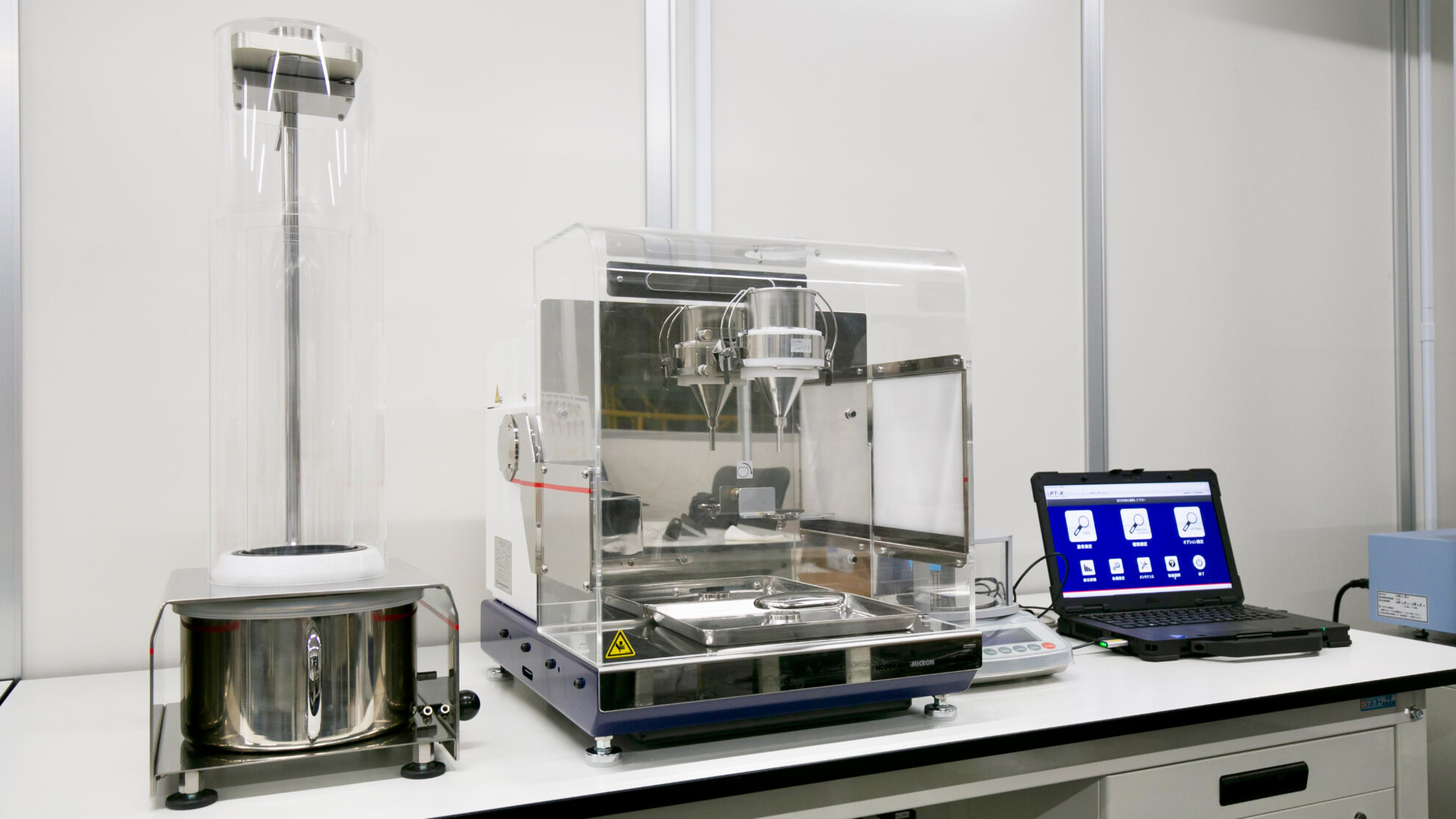

CHARACTERISTICS TESTER: 1 unit

Model: PT-X

Measurement items: Angle, compaction, bulk density, etc.

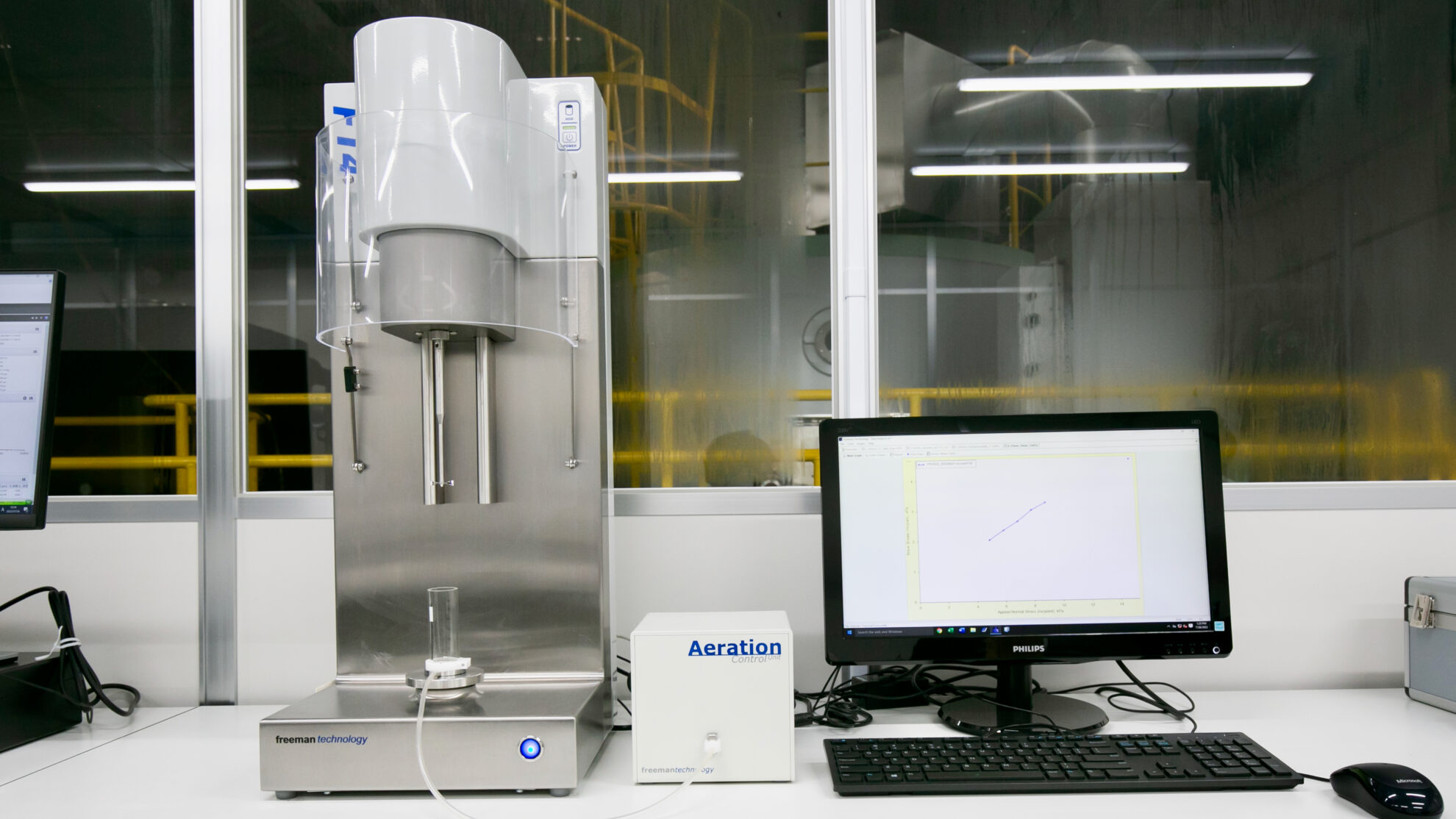

POWDER RHEOMETER: 1 unit

Model: FT4

Measurement items: Stability, compressibility, bulk density, etc.

SURFACE AREA ANALYZER: 1 unit

Model: TriStar II Plus3030

Measurement items: Specific surface area, pore distribution

DENSITY ANALYZER: 1 unit

Model: Accupic II

Measurement item: Density

Note: Gas displacement method

CRUSHING FORCE ANALYZER: 1 unit

Model: NS-A200

Measurement item: Particle crushing force

WET RHEOMETER: 1 unit

Model: MCR302e

Measurement items: Dynamic flow properties

VISCOMETER: 1 unit

Model: DVE

Measurement item: Viscosity

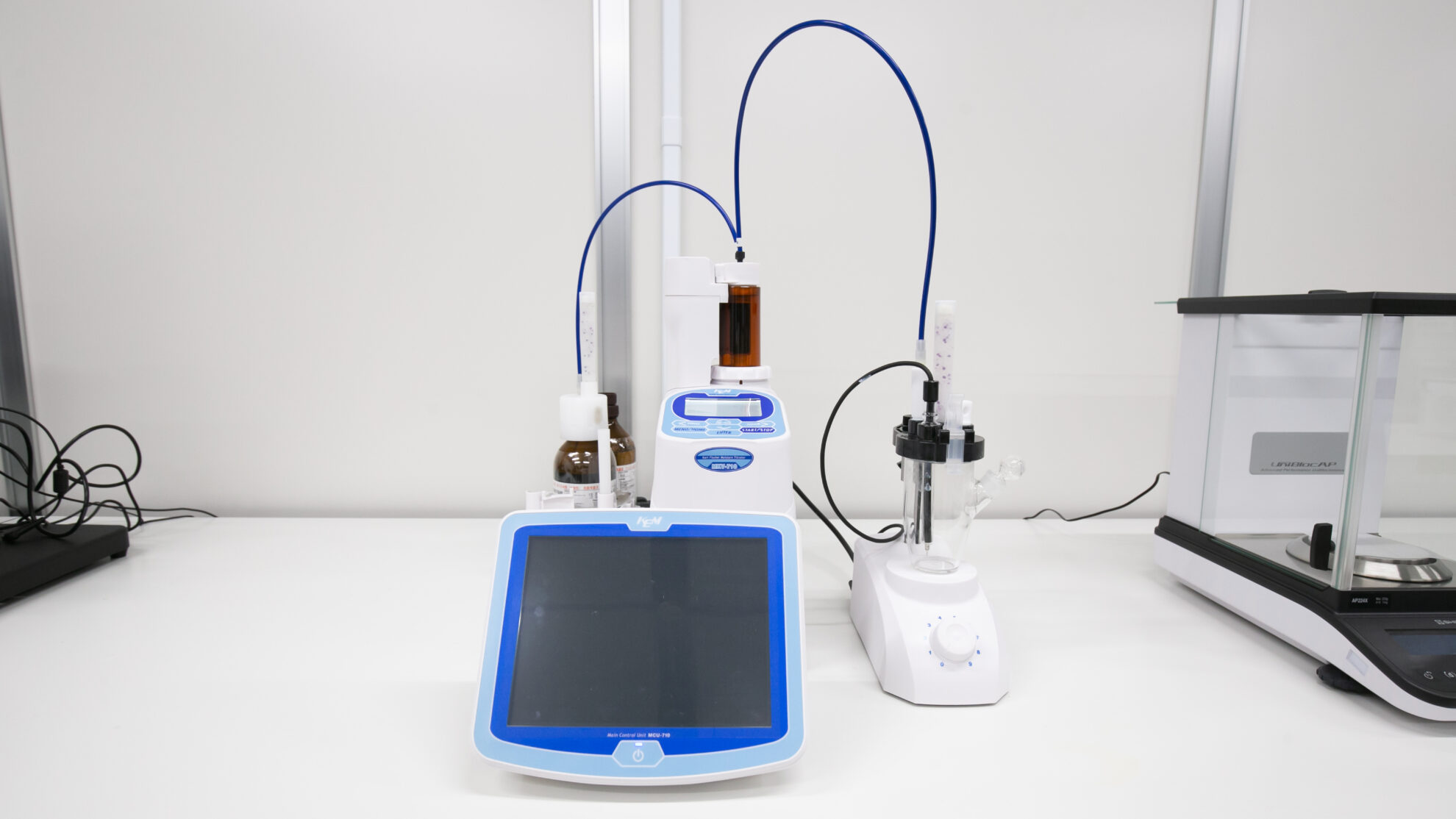

MOISTURE ANALYZER: 1 unit

Model: MKV-710S

Measurement item: Moisture content

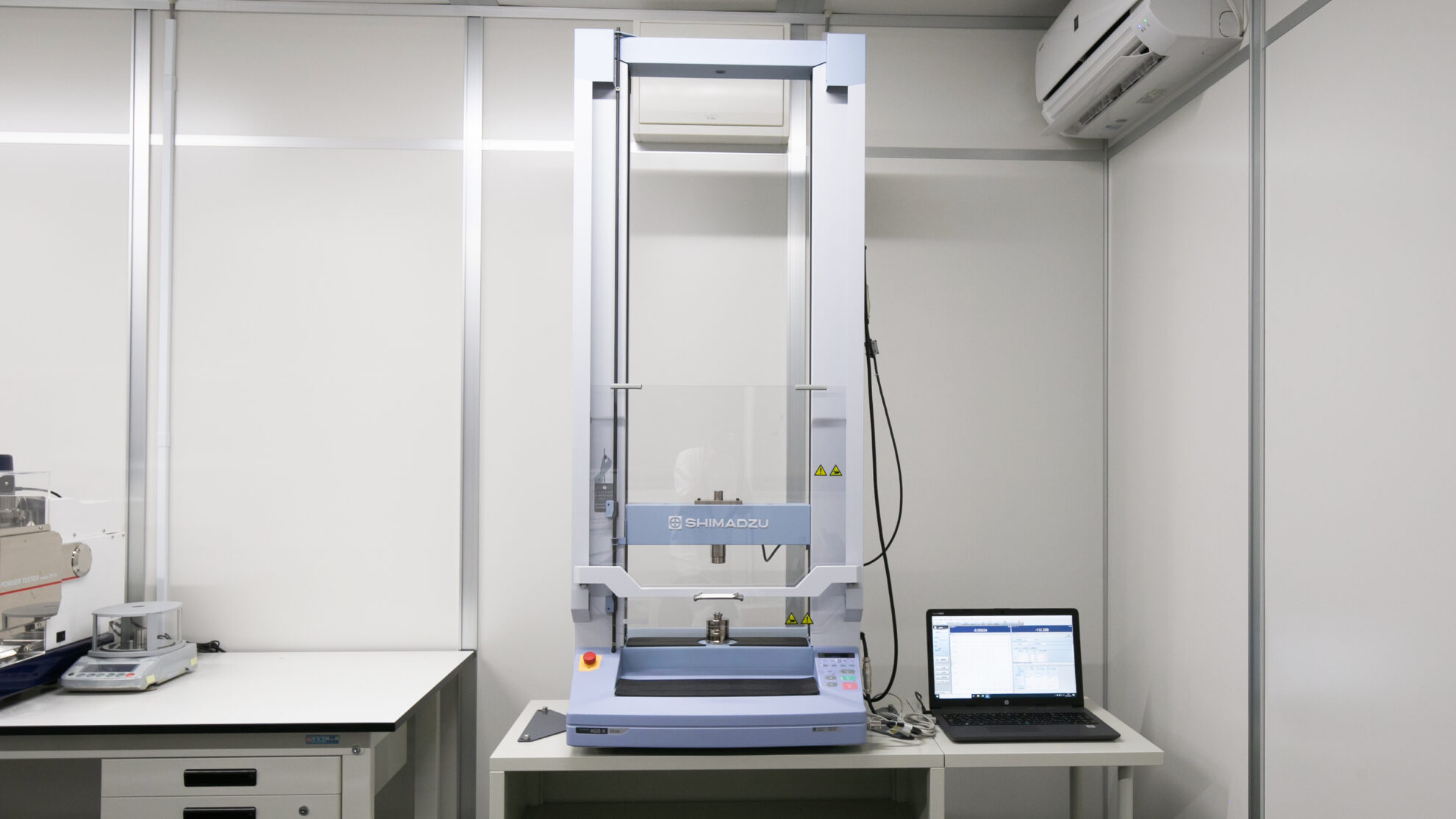

UNIVERSAL TESTER: 1 unit

Model: AGS-10kN

Measurement items: Tension, compression

How to apply

1. Contact

Please contact us via the contact form or by phone.

2. Initial Q&A session

We will discuss the outline of your plan by phone, email, face-to-face, online, etc. We will also provide information about our Powder Technical Center and inform you of possible facilities to be selected and time slots available. Depending on the facility selected, reservations may be booked for several months, so we ask you to schedule your trial date early.

3. Submission of Trial/Contract Processing/Analytical Measurement Confirmation Sheet

Please fill out and submit the Trial/Contract Processing/Analytical Measurement Confirmation Sheet. You can skip items that are unclear or non-disclosure information. *We ask for detailed disclosure regarding the safety and environmental information.

4. Submission of a quotation

We will submit you a quotation based on the Trial/Contract Processing/Analytical Measurement Confirmation Sheet.

5. Schedule adjustment

Trial date will be fixed after we receive your formal request.

6. Shipping your material

Ship your material by the day before the trial date. If you visit our PTC and observe your trial on the day, you may bring your material with you.

7. Conducting your trial

If you observe your trial, we will conduct the trial while discussing operating conditions with you. Even if you are not present, we can adjust the conditions while reporting the progress over the phone.

8. Submission of Trial/Contract Processing/Analytical Measurement Report

A report will be submitted within one week from the trial date.

FAQ

Q. Is it possible to test a small amount?

A. By using a small facility, it is possible to test from approx. 1L at a time.

Q. What kinds of materials do you accept for trials?

A. We generally handle a wide variety of applications. However, we may not be able to accept some materials due to safety and/or environmental reasons.

Q. Is it possible to request a trial without disclosing the material information?

A. Regarding safety and environmental aspects, we must ask you to present the detail information including SDS, etc. and we will evaluate whether or not we are able to conduct the trial. We may also enter into a confidentiality agreement with you.

Q. Is it possible to witness a trial?

A. Yes, we always welcome you at our PTC.

Q. Is it possible to request only powder analysis/measurements?

A. Yes, we are pleased to support for your analytical measurements.

Q. How are costs estimated?

A. Powder processing trial costs are estimated on a daily basis, including the cleaning process of the facility. It is also possible to conduct the trial on multiple consecutive days. Analytical measurements are estimated based on a sample quantity basis. Liquid material preparation, wet pulverizing, freeze drying, molding and sintering are estimated in working-hour basis.

Q. Can you inform about the reservation status?

A. We can notify you of the latest reservation status by phone or email. We usually take reservations 1 to 3 months in advance. You can also make a reservation on the waiting list.