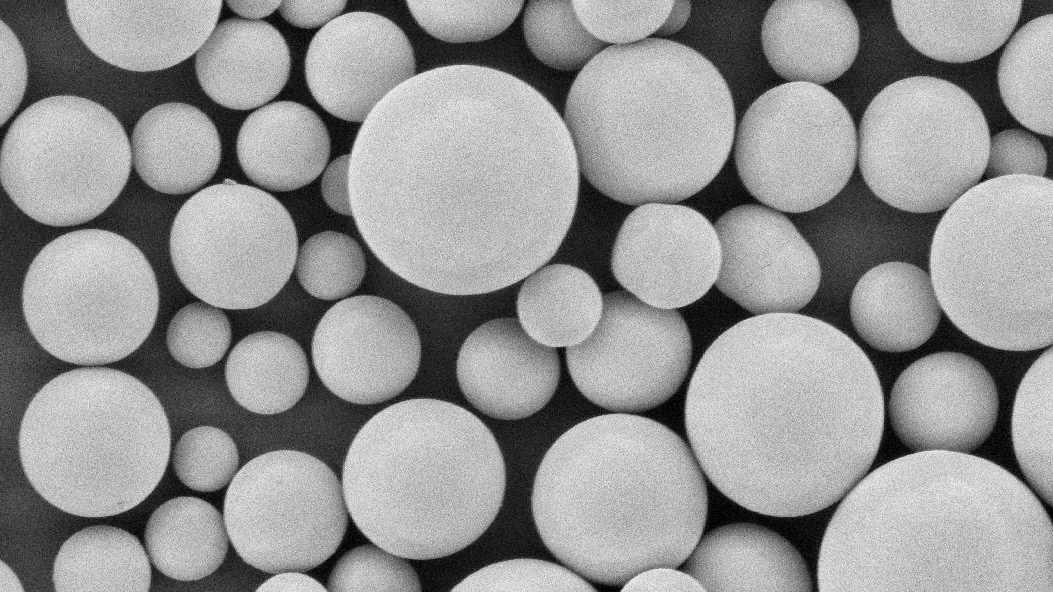

We provide contract processing services for spray drying, spray cooling, freeze granulation, freeze drying, wet pulverizing, and nano powder wet pulverizing. We support your journey from initial R&D phase to small-scale and full-scale production. Utilize our facilities for sudden increase in demand and/or high-mix low-volume production. We also support you during the O&M period of your facilities or interim production until you complete your new facility installation. We provide processing services tailored to your needs at a total of three locations: two domestic Powder Technical Centers (PTC1 and PTC2) and ASEAN Powder Technical Center (PTC ASEAN) in Thailand.

Characteristics

- Consistent support from R&D to mass production

- One-stop service from powder processing to analytical measurements

- Latest facilities are available without initial investment and maintenance costs

- Time saving by outsourcing your production

- Ideal for low-volume production that does not fit your production capacity

Services

![]()

![]()

![]()

![]()

![]()

![]()

Examples of challenges in powder processing

- Powder processing is required, but since we do not have a facility, it has to be outsourced.

- We have newly developed a new product and need to outsource the production.

- Although our new facility is in progress, we need to start production before it becomes operational.

- Since our facility is being aged, we want to switch our production to outsourcing.

- As our facility is too large for some low-volume productions, we want to outsource them.

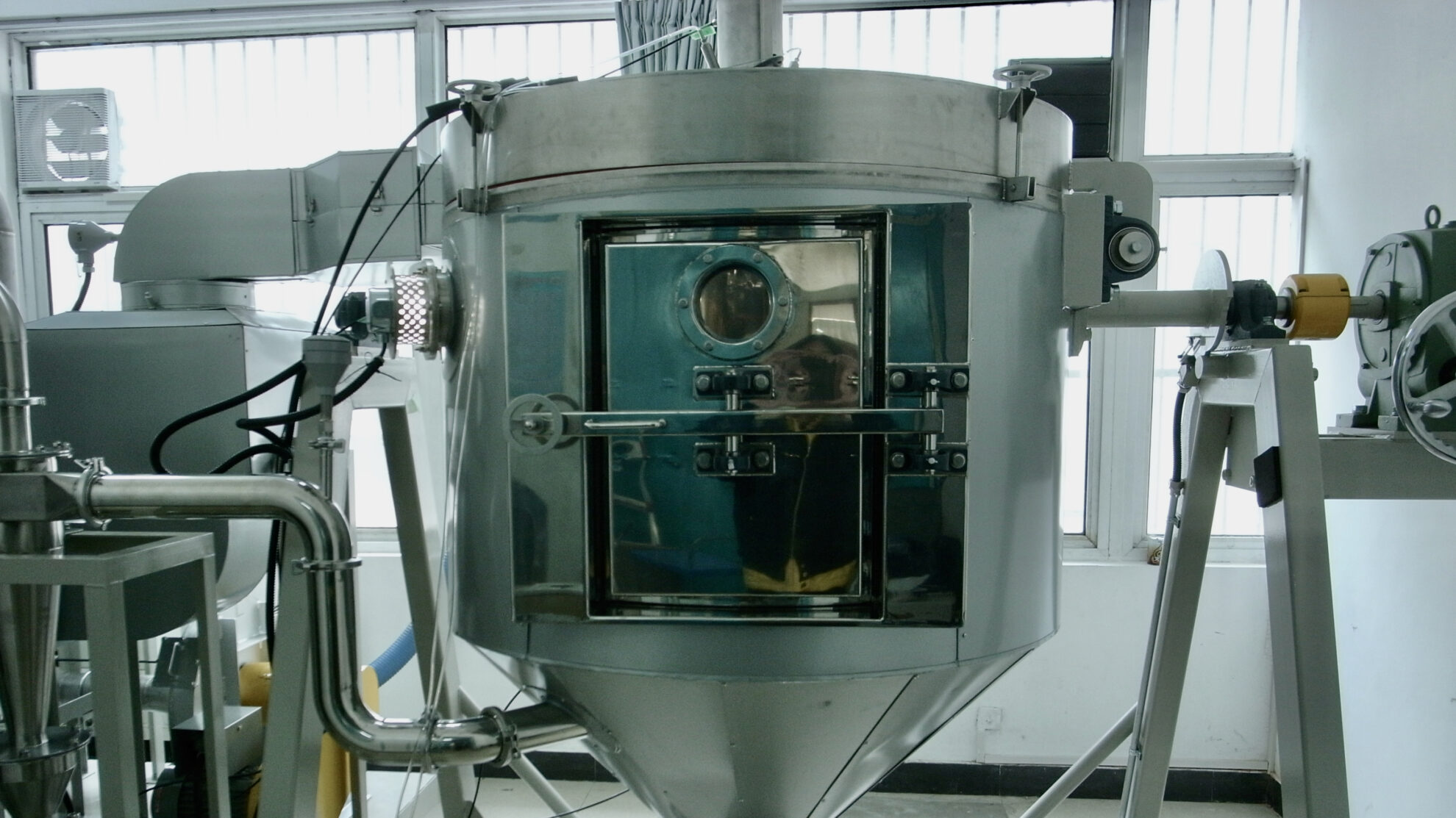

Facilities

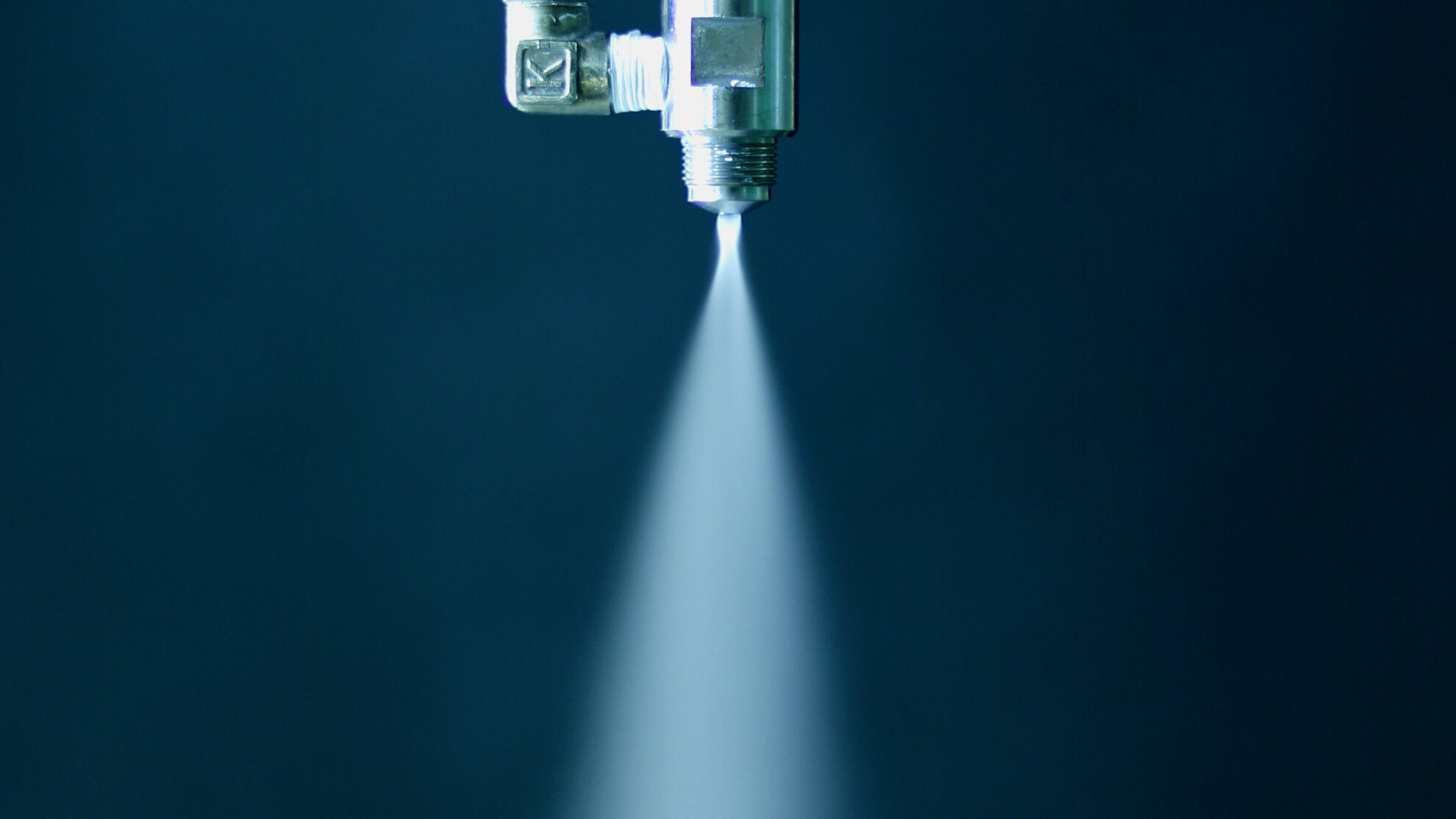

Spray dryers

SB39: 4 units

Chamber diameter: φ387mm

Atomization system: Two-fluid nozzles

Water evaporation vol.: Up to 3kg/h

Note: Closed-cycle system available

TR160: 1 unit

Chamber diameter: φ1600mm

Atomization system: All systems available

Water evaporation vol.: Up to 15kg/h

Note: Closed-cycle system available

P260: 2 units

Chamber diameter: φ2600mm

Atomization system: All systems available

Water evaporation vol.: Up to 30kg/h

D350: 1 unit

Chamber diameter: φ3500mm

Atomization system: All systems available

Water evaporation vol.: Up to 50kg/h

SB39: 1 unit

Chamber diameter: φ387mm

Atomization system: Two-fluid nozzles

Water evaporation vol.: Up to 3kg/h

Note: PTC ASEAN (Thailand)

TR80: 1 unit

Chamber diameter: φ800mm

Atomization system: Rotary atomizers, Two-fluid nozzles

Water evaporation vol.: Up to 3kg/h

Note: PTC ASEAN (Thailand)

P260: 1 unit

Chamber diameter: φ2600mm

Atomization system: All systems available

Water evaporation vol.: Up to 30kg/h

Note: PTC ASEAN (Thailand)

Spray coolers

Spray cooling processing is available using the above spray dryers.

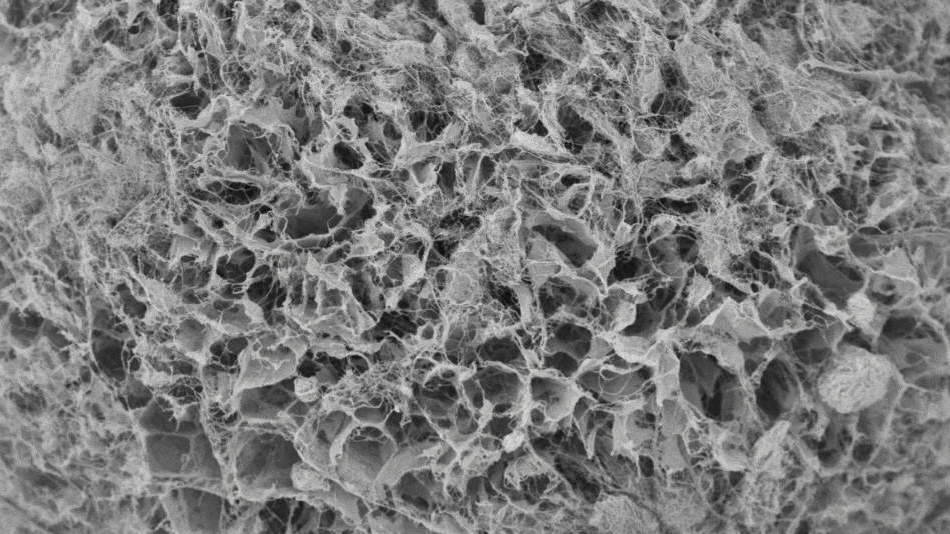

Freeze granulator

LS-6: 1 unit

Container diameter: φ120mm

Atomization system: Two-fluid nozzles

Material feed capacity: Up to 6kg/h

Cooling temperature: −196℃

Cooling system: Wet cooling system

CS30: 1 unit

Chamber diameter: φ300mm

Atomization system: Two-fluid nozzles

Material feed capacity: Up to 15kg/h

Cooling temperature: −10 ~ −120℃

Cooling system: Dry cooling system

CS220: 1 unit

Chamber diameter: φ2200mm

Atomization system: All systems available

Material feed capacity: Up to 320kg/h

Cooling temperature: −10 ~ −50℃

Cooling system: Dry cooling system

Freeze dryers

FDU-2110: 1 unit

Tray volume: 700ml × 6 stages

Cold trap capacity: 3kg

Cold trap temperature: −80℃

FD-551: 1 unit

Tray volume: 8000ml × 3 stages

Cold trap capacity: 10kg

Cold trap temperature: −45℃

TFD-10: 1 unit

Chamber volume: 85L

Cold trap capacity: 10kg

Cold trap temperature: −40℃

RHEOFREED: 1 unit

Chamber volume: 160L

Cold trap capacity: 30kg

Cold trap temperature: −45℃

How to apply

1. Contact

Please contact us via the contact form or by phone.

2. Initial Q&A session

We will discuss the outline of your plan by phone, email, face-to-face, online, etc. We will also provide information about our Powder Technical Center and inform you of possible facilities to be selected and production schedule. Depending on the facility selected, reservations may be booked for several months, so we ask you to schedule your processing date early.

3. Submission of Trial/Contract Processing/Analytical Measurement Confirmation Sheet

Please fill out and submit the Trial/Contract Processing/Analytical Measurement Confirmation Sheet. You can skip items that are unclear or non-disclosure information. *We ask for detailed disclosure regarding the safety and environmental information.

4. Submission of a quotation

We will submit you a quotation based on the Trial/Contract Processing/Analytical Measurement Confirmation Sheet.

5. Schedule adjustment

Processing schedule will be fixed after we receive your formal request.

6. Shipping your material

Ship your material by the day before the processing date.

7. Conducting your processing

We will conduct the processing according to predetermined processing conditions.

8. Delivery of processed products

We will deliver processed products according to the predetermined schedule.

9. Submission of Trial/Contract Processing/Analytical Measurement Report

A report will be submitted within one week from the delivery date.

FAQ

Q. Is it necessary to make a trial before contract processing?

A. An initial trial is required to determine the processing conditions.

Q. What kinds of materials do you accept for contract processing?

A. We generally handle a wide variety of applications. However, we may not be able to accept some materials due to safety and/or environmental reasons. We do not undertake contract processing of food and pharmaceutical products. For some food applications, we may be able to introduce you to our partner companies.

Q. Is it possible to request a processing without disclosing the material information?

A. Regarding safety and environmental aspects, we must ask you to present the detail information including SDS, etc. and we will evaluate whether or not we are able to conduct the processing. We may also enter into a confidentiality agreement with you.

Q. Is it possible to witness a processing?

A. Yes, we always welcome you at our PTC.

Q. How is the processing cost estimated?

A. After setting the processing conditions through a trial, we will select the facility to be used according to the amount of processing and estimate the cost.

Q. Can the production schedule be changed flexibly?

A. It depends on the availability of the facility. However, we will be as flexible as possible and propose an optimal alternative processing plan.