We support maintenance, repair, modification, and renewal of existing processes. In addition to our own products, we also actively support products and processes made by other suppliers in order for further improvements of performance, quality control and energy saving.

Maintenance & Repair of existing processes

Proper maintenance of existing processes can improve the entire process lifecycle values. Appropriate maintenance and repairs are necessary for long-term and stable operations of industrial processes. In addition to our own products, we also provide repair and maintenance services for processes manufactured by other suppliers in the technical areas that we handle such as powder technology, biotechnology and precision cleaning technology. In addition to maintenance and repair works, we also support calibration and validation work.

Maintenance & Repair examples (powder technology)

- Maintenance and repair of our spray dryers, spray coolers, and freeze granulators

- Maintenance and repair of the former Sakamoto Giken spray dryers and spray coolers

- Repair of spray dryers and spray coolers made by other suppliers

Maintenance & Repair examples (biotechnology)

- Maintenance and repair of our incubator shakers, platelet shakers and high-pressure steam sterilizers

- Maintenance and repair of the former Takasaki Scientific Instruments incubator shakers

- Repair of incubator shakers made by other suppliers

Maintenance & Repair examples (precision cleaning technology)

- Maintenance and repair of our precision cleaning systems

- Maintenance and repair of the former ASK cleaning systems

- Maintenance and repair of the former Asuka Seiki Sangyo cleaning systems

- Repair of cleaning systems made by other suppliers

Modification & Renewal of existing processes

We support modifications and renewals that contribute to increasing the values of industrial processes, such as updating entire processes due to aging or requirements for increasing capacity, productivity and/or energy efficiency. In addition to improving the entire process, it is also possible to improve individual components or add our latest technologies. We also have a number of achievements in updating entire processes by reusing usable components and modifying only outdated ones.

Modification & Renewal examples (powder technology)

- Energy saving (recycling waste heat, strengthening insulation level, etc.)

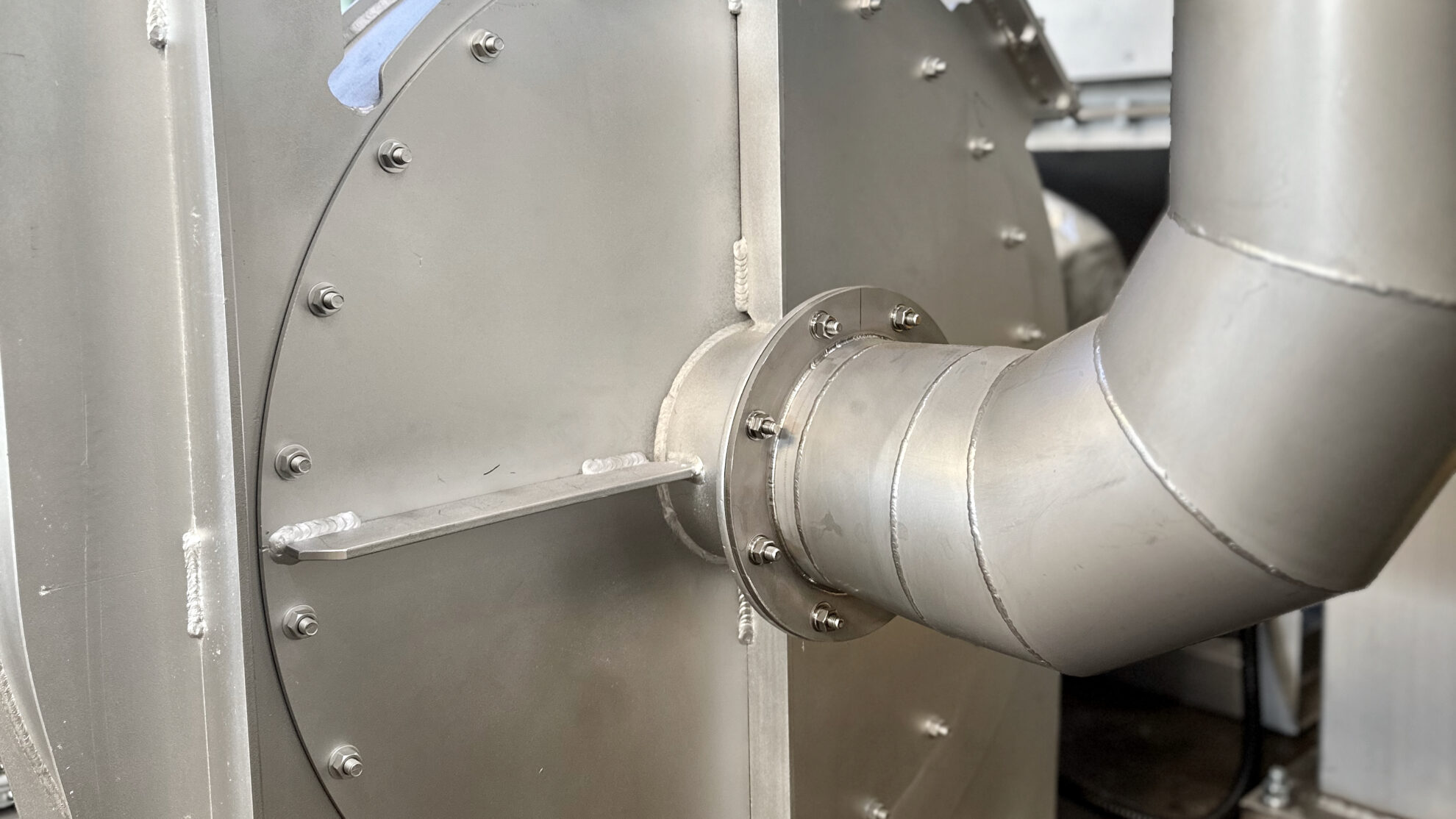

- Renewal of aging chambers, ducts, piping and structures

- Capacity enhancement (pumps, heaters, heat exchangers, blowers, filters, instrumentation, etc.)

- Heat source change (electric, gas, steam, etc.)

- Cooling source change (chiller, refrigerant, etc.)

- Improvement and update of rotary atomizers made by other suppliers

- Improvement and update of atomization systems (rotary atomizers and various nozzles)

- Improvement of worn parts (material changes, hardening treatment, thermal spraying treatment, etc.)

- Lining treatment to reduce product adhesion (PTFE lining, etc.)

- Update of control panels and electrical wiring

- Improvement of safety interlock systems (addition of sensors and instruments, modification of software, etc.)

- Update of process controls, software and communication systems

Modification & Renewal examples (biotechnology)

- Renewal of shaking panels and trays (flasks, test tubes, beakers, chips, etc.)

- Update of shaker heaters and refrigerators

- Change of shaker control temperature range

- Update of high-pressure steam sterilizer heat source

- Renewal of high-pressure steam sterilizer vessels, trays, etc.

- Update of control panels and electrical wiring

- Improvement of safety interlock systems (addition of sensors and instruments, modification of software, etc.)

Modification & Renewal examples (precision cleaning technology)

- Energy saving (distillation regeneration, water regeneration, drying, etc.)

- Renewal of aging lines (tanks, piping, gaskets, pumps, valves, etc.)

- Renewal of corroded areas (sheet metal, structures, etc.)

- Improvement and update of cleaning systems (ultrasonic devices, nozzles, barrels, vacuum pumps, etc.)

- Improvement and renewal of conveyers (basket, net conveyor, hoop, etc.)

- Update of control panels and electrical wiring

- Improvement of safety interlock systems (addition of sensors and instruments, modification of software, etc.)

- Update of process controls, software and communication systems

Case study

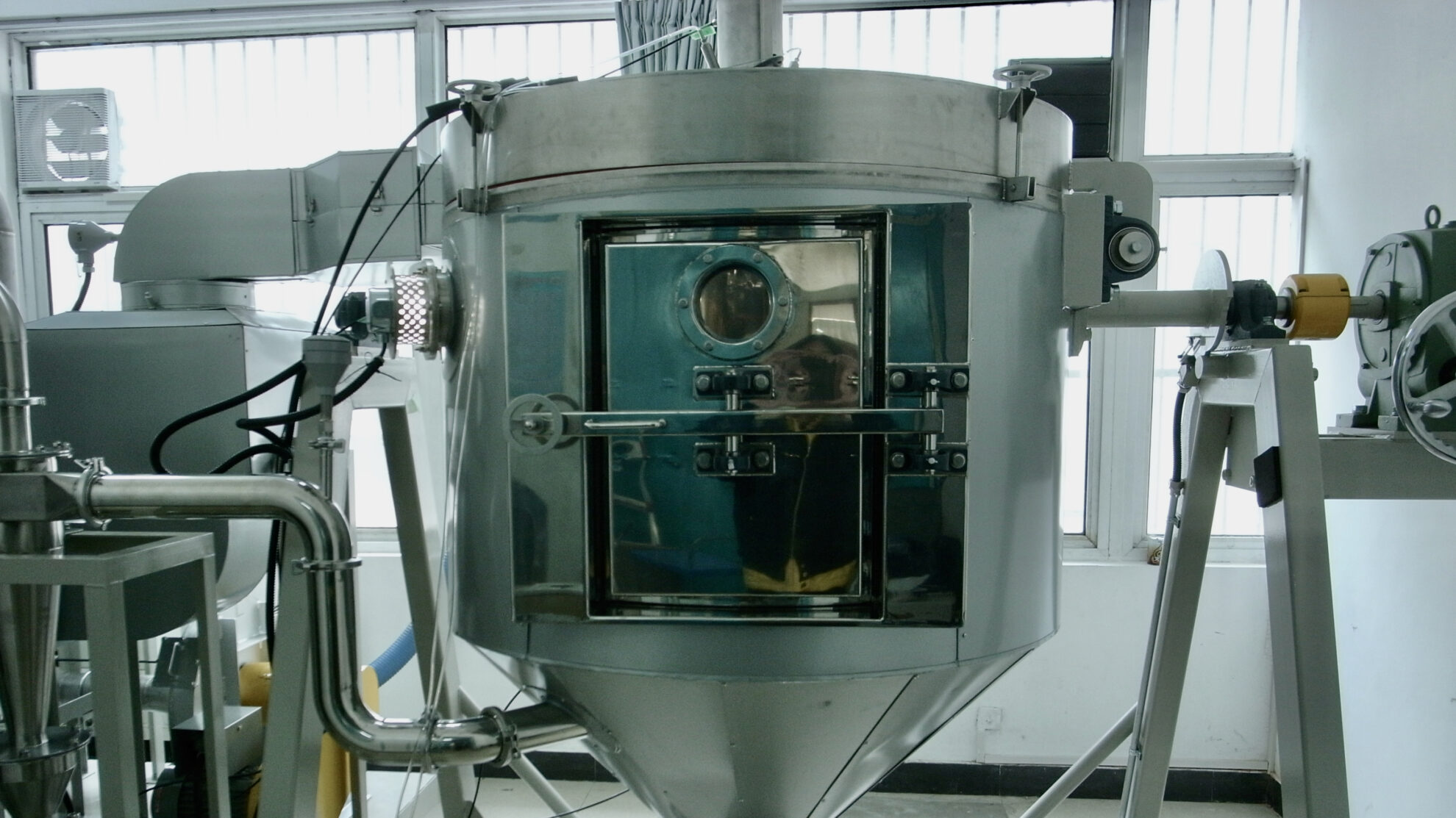

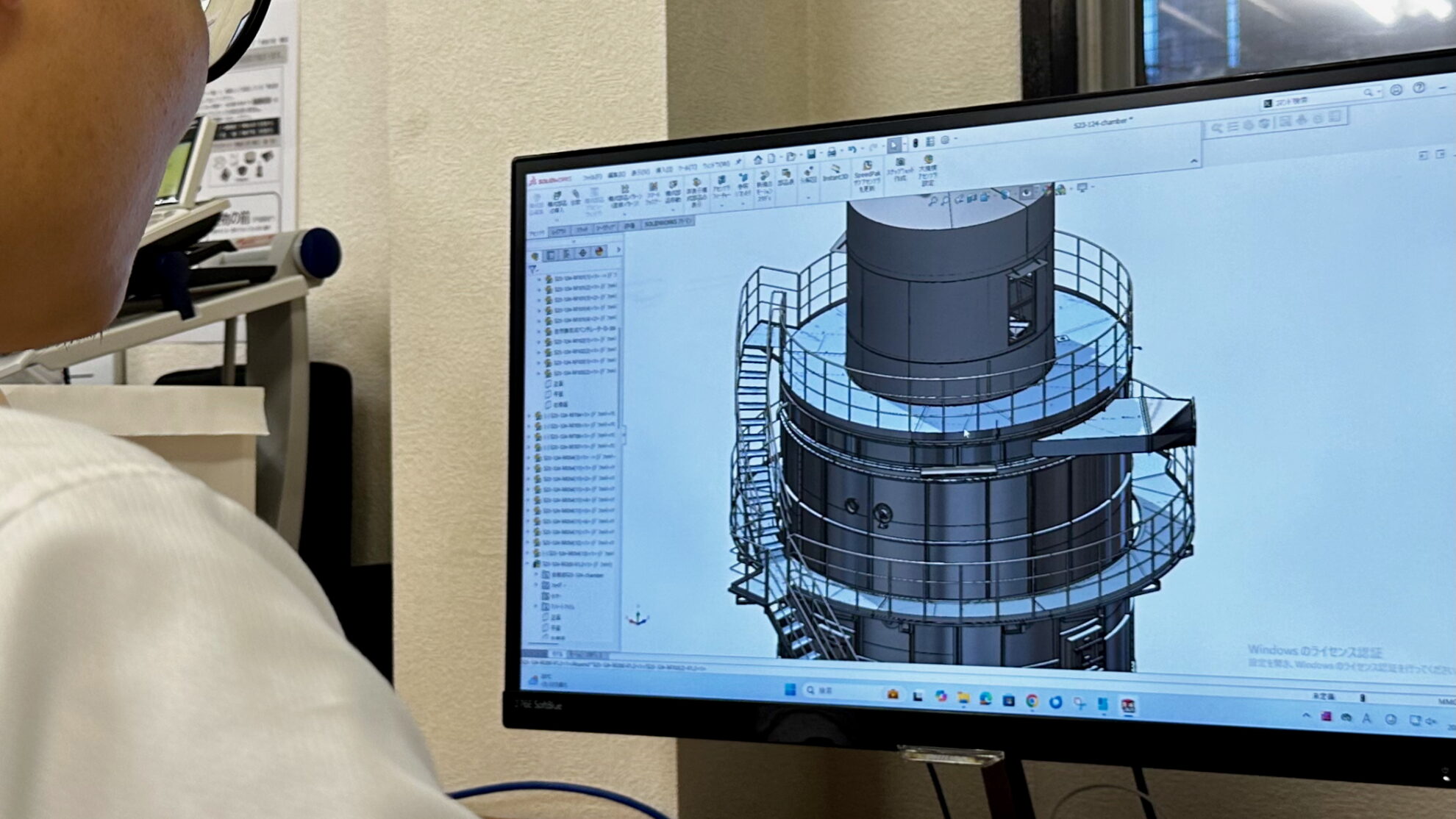

Renewal of production-scale spray dryer (Japan)

Our customer, a Japanese pharmaceutical manufacturer, manufactures active pharmaceutical ingredients as a contract manufacturing organization (CMO). The customer’s production-scale European-made spray dryer had been in operation for over 40 years and was becoming increasingly obsolete. Therefore, the customer was looking for an engineering company that could update only the aging parts. The product manufacturing contract that the customer had with its customer was to continue production for a long period of time, so GMP compliance of the manufactured products and consistency in quality control were required. In addition, since we were obligated to comply with the product production plan, we were also required to commit to the construction timeline.

In cooperation with the customer, we examined the limited existing documents and conducted an on-site investigation of the internal structure of the process and the extent of its deterioration. After that, we made the missing documents and determined the scope of updates. Specifically, we decided to update the drying chamber, ducts, powder conveying lines, and other parts that come in contact with powder, as well as the pedestals and stages that were subject to corrosion, and some equipment that lacked capacity. The project was officially launched, and we designed and manufactured the goods, selected and arranged replacing components, and moved to on-site construction. Renewing a large spray dryer with a height of over 20 meters was highly difficult as the new items were installed at the same time as the demolition work, but thanks to the cooperation with our engineering partners, we were able to successfully complete the project. After checking I/O and confirming safety interlocks, we moved to commissioning. After the commissioning, we confirmed that the spray dryer’s capacity was the same as before the update.

* Images may differ from the actual project and may be used for illustrative purposes only.

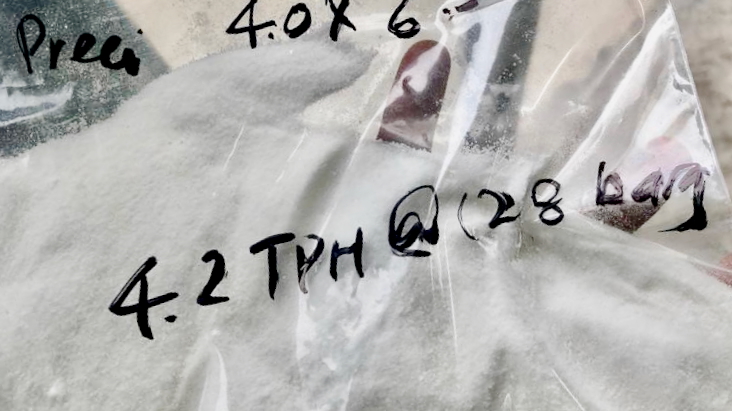

Modification of production-scale spray cooler (Malaysia)

Our partner, a Malaysian engineering company, was facing challenges in the project to build a new production-scale spray cooler. The user, a global feed manufacturer, was planning a new production facility for saturated fatty acid granules using spray cooling solidification. The user already owns several spray coolers and has been in production for many years, so they had a certain production technics and know-how in spray cooling. Therefore, the user asked our partner and local manufacturing companies to build a new plant based on the specifications provided by the user itself. Although our partner had more than enough experience in plant engineering, they were unable to verify the specifications presented because they did not have the experience of engineering a spray cooling process. Additionally, the applications to be produced in this project contained several grades that had never been produced in the existing production processes, and it was unclear whether these applications could be produced within the required particle size range.

We carefully examined the required specifications presented by the user and calculated material balance and heat balance for each application for the process verification. As a result, we found that some specifications, such as process gas flow rate and atomization system, had to be changed in order to meet the required specifications. Since the production process was already underway, we responded by modifying the atomization system, process gas disperser, and some components that could be modified at the time. In order to meet all of the requirements for each application, we determined to apply two atomization systems: rotary atomization and universal pressure nozzle atomization which is our own unique technology of adjustable spray directions. By switching the atomization system, it was possible to produce multiple applications and recipes within the required particle size range. When selecting the atomization system, we conducted trials using actual raw materials at our powder technical center in Japan. During the on-site construction, our engineering team also assisted as supervisors. The closed-cycle spray cooling process, which has a maximum throughput of 3t/h, the total height of 20m, and is equipped with CIP system, was successfully completed under our partner’s superior engineering work. The particle size of the new applications and recipes also met the required specifications, and commercial production has continued to this day while maintaining a high yield.

* Images may differ from the actual project and may be used for illustrative purposes only.

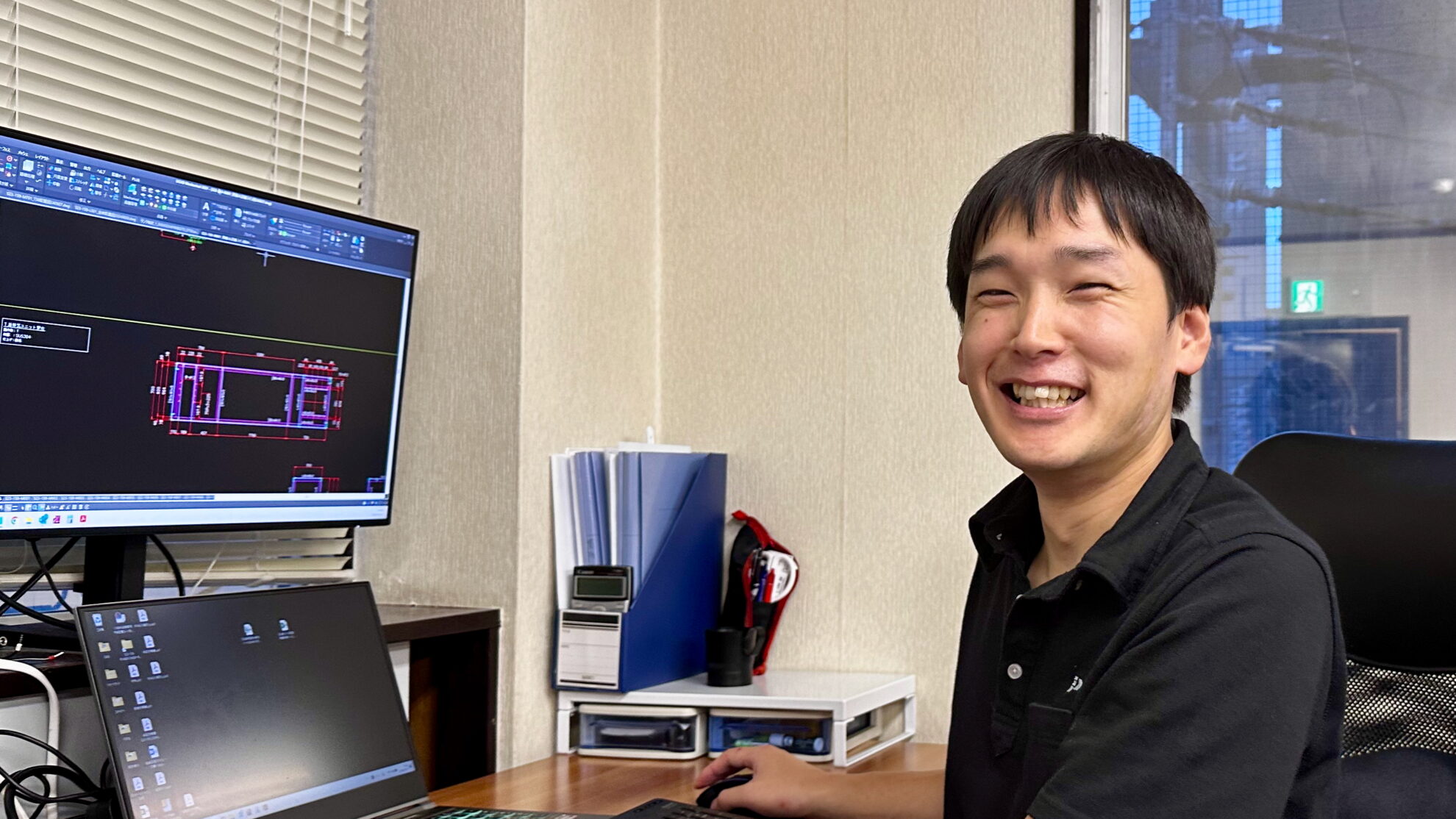

Update of rotary atomizer (Japan)

Our customer, a Japanese chemical manufacturer, had been using a spray dryer made overseas for over 30 years. The customer had been maintaining operating rates through proper maintenance, but the frequency of rotary atomizer failures was increasing due to aging. Therefore, they were considering updating the rotary atomizer. The rotary atomizer made overseas tend to have high costs for replacement of consumables and worn parts, as well as overhaul, and delivery times are longer than those from domestic manufacturers, so they can be a hindrance in O&M for customers. The customer also owns a spray dryer made by us and was aware that we could support them update their rotary atomizer made by other suppliers. After comparing the replacement cost with future maintenance costs of the existing rotary atomizer, they decided to update the atomization system. The existing rotary atomizer with a maximum throughput of 2t/h was a belt-drive type equipped with oil circulation cooling unit. Oil was often leaked during operation. Additionally, when producing certain applications, there were instances in which raw materials became clogged within the rotary atomizer. A specially shaped φ500mm rotary atomizer disc was operated at high speed to produce products with a particle size of Dv50: 25μm.

After the project was launched, we conducted trials using actual raw materials at our powder technical center to verify the reproducibility of the granules’ physical properties. In addition, we conducted an on-site investigation of the spray dryer production using the existing rotary atomizer to verify clogging of specific applications. During the on-site investigation, we disassembled the rotary atomizer and inspected after the production was finished. We then worked with the customer to verify both the physical properties of the liquid material and the operating conditions of the spray dryer. Based on the investigation results, we conducted a trial using our own liquid distributor which is a part of a rotary atomizer to prevent clogging. As a result of the trial, we were able to obtain reproducibility of the product’s physical properties, and there was also a prospect of eliminating clogging for specific applications, so we proceeded to the basic design of a new rotary atomizer. A new rotary atomizer must have been carried up to the ceiling of the existing spray dryer and must have fitted within dimensions that did not interfere with the building. In addition, by matching the atomization position with the existing rotary atomizer, atomized droplets must have come into contact with the process hot air at the same position in the drying chamber. As for the cooling mechanism of the new rotary atomizer, we selected an oil-free type air cooling system so that the risk of oil leakage that occurred with existing rotary atomizer was eliminated. The shape of the rotary atomizer disc was the same except for the shaft fitting, as it was necessary to maintain consistency in the quality of their products. The renewal project progressed as planned, and after on-site delivery, installation work, control panel modification work, and commissioning, we successfully passed the acceptance inspection. The throughput during production and the physical properties of the product were within the same range as before the update, and commercial production has continued to this day.

* Images may differ from the actual project and may be used for illustrative purposes only.

Update of precision cleaning system (Thailand)

Our customer, a Japanese jewelry manufacturer, uses our precision cleaning systems on multiple production lines in its domestic and international factories. At our customer’s Thai factory, they were using multiple stripping and cleaning/drying systems to remove the plating film in order to recycle defective products that occurred during the metal plating process. The operations team in charge of the stripping process was responsible for loading defective products into the stripping tank, transporting them to the cleaning system after stripping, and switching to the drying system after cleaning. Although the stripping, cleaning, and drying processes were standardized, a certain percentage of defects remained due to the separation of the processes and the need for transport and changeover work. Because a variety of chemicals were used in the stripping process, there were also residual safety risks. The customer decided to adopt our fully automatic stripping and cleaning system to automate a series of those processes.

Together with the customer, we investigated the existing process and created a conceptual design to automate the entire process. At the same time, trials were conducted at our cleaning test center in Japan in order to maintain the performance in stripping, cleaning, and drying processes. After verification through field trials, the evaluation of stripping performance and cleanliness passed the inspection test, and we also had a prospect of process automation in the basic design, so we proceeded to the system manufacturing process. The fully automated system continuously processes from stripping to cleaning and drying. Each batch of workpieces set up on a special frame jig is immersed in four baths of chemical solution A, then rinsed with RO water and followed by ultrasonic cleaning, before being transferred to the next stage of chemical solution B. Treatment with chemical solution B proceeds in the same way as the process with chemical solution A, and then moves to the solvent treatment process. After solvent treatment, workpieces are moved to the next cleaning and drying process. The workpieces are automatically discharged after ultrasonic treatment using RO water, a cleaning process with alkaline chemicals, a final rinsing process using pure water, and a drying process. Each process for chemical solutions, solvents, alkaline chemicals, RO water and pure water is equipped with an overflow to the pre-tank, a circulation system via a pre-tank and a filtering system. In addition, a distillation regeneration system is incorporated into the solvent process, and recycled solvent is automatically supplied into the process.

With this update, the customer was able to significantly reduce man-hours and eliminate defective rates. The new full-automatic process reduced the number of workers required in operation, and the use of a liquid circulation system and distillation regeneration system improved the efficiency of chemicals and solvents consumption, reducing operating costs for the entire process. Subsequently, we introduced our new automatic cleaning system to another line, the cleaning process for precision metal products for further automating the factory. While maintaining quality, we have eliminated remaining safety risks and the customer has continued to operate to this day.

* Images may differ from the actual project and may be used for illustrative purposes only.

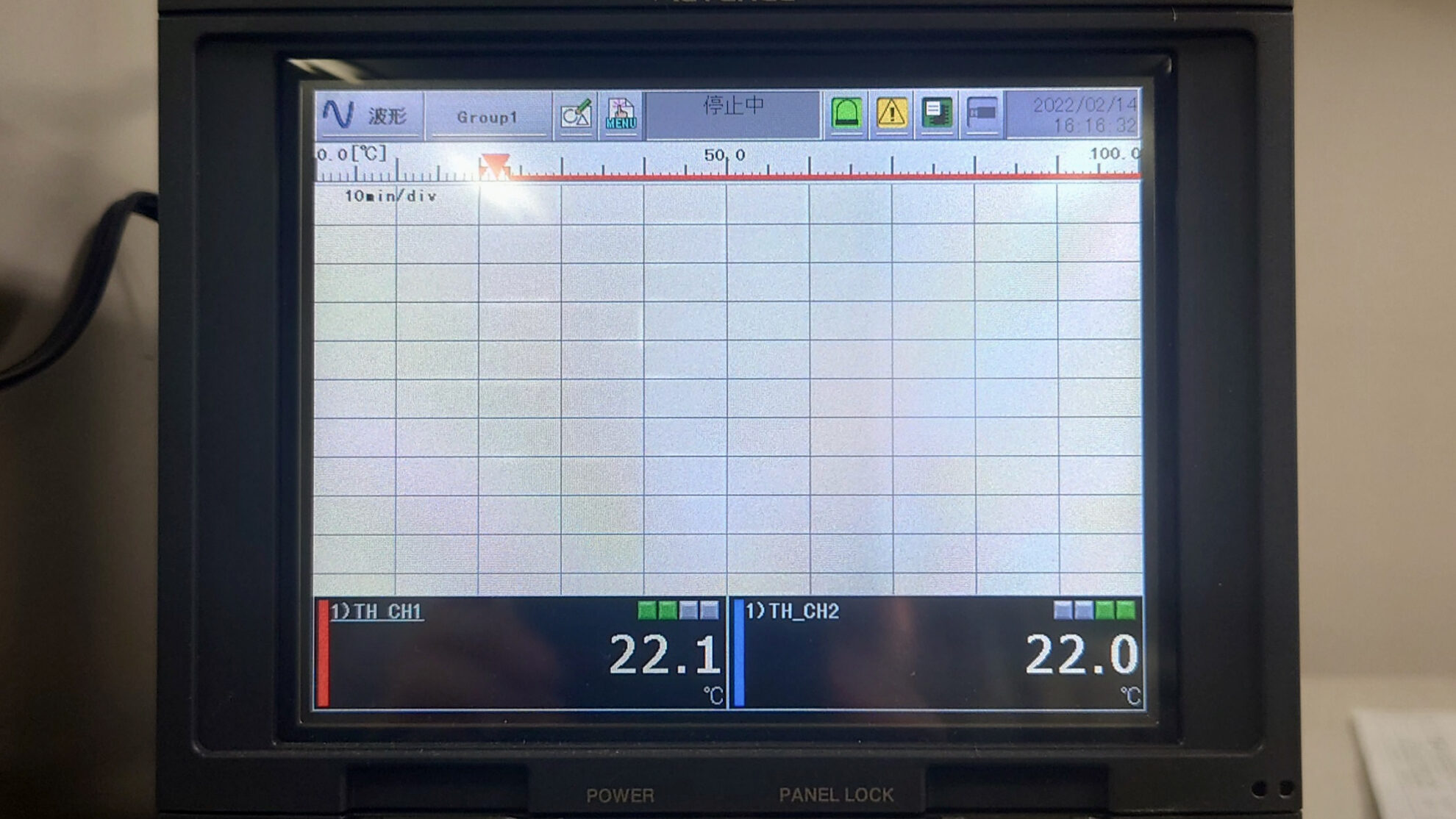

Update of incubator shaker (global)

Our customer, a Japanese pharmaceutical manufacturer, is a global company with production bases around the world and cutting-edge fermentation technology. The customer consistently uses our incubator shakers at their domestic and international R&D centers and production sites. Our large-scale incubator shakers boast unrivaled robustness and stability, thanks to our large-capacity shaking technology developed over many years. Because incubator shakers often operate continuously 24 hours a day or for several days or weeks, the shakers must be robust enough to prevent breakdowns. Our incubator shakers are in operation around the world, and some have been in operation for over 60 years. We continue to maintain our shakers operating in Japan and overseas to this day.

The customer standardizes the specifications of the incubator shakers they use, depending on the product and production scale. By standardizing the models, it is possible to maintain consistency in production conditions. Additionally, in addition to globally standardized SOPs, the shaker itself is the same and the usability remains the same, which helps reduce operator errors. From O&M perspective, as shakers are the same, repair parts can also be shared, making it possible to standardize maintenance work as well. Whether the maintenance work is carried out by the customer’s engineering team or our field service team, it helps streamline maintenance operations and reduce costs. With the customer’s network of locations spread all over the world, their R&D and production sites are dispersed. However, since the same incubator shaker is used, it is easier not only to introduce new shakers but also to manage the maintenance work when updating existing shakers. It is possible to adjust the necessary number and scale according to the growth of each location. The customer also relocate shakers among their locations as necessary. Because the shakers are the same model, the new operator can use the shaker immediately upon arrival without having to review the manual or receive operational training.

* Images may differ from the actual project and may be used for illustrative purposes only.