MEISTER

Automatic, Powerful & Low Consumption

High performance, yet low chemical consumption

![]()

MEISTER α

Hydrocarbon-based and silicon-based chemicals (explosion-proof)

![]()

MEISTER β

Fluorine-based, bromine-based, chlorine-based chemicals

![]()

MEISTER Ω

Non-halogen, non-flammable chemicals (explosion-proof)

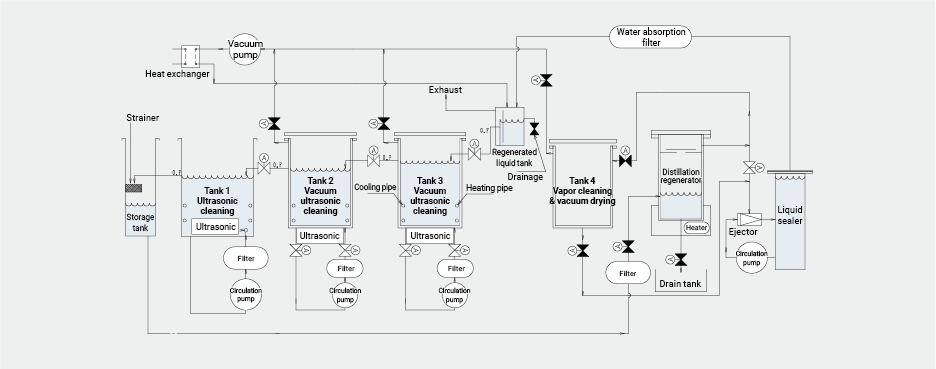

Vacuum US × double immersion × vapor cleaning

Our double immersion cleaning is the perfect ful-auto process ‒ the first step cleaning, and the second step finishing cleaning. The solvent is replaced automatically at each step. Vapor cleaning and rinsing, as the third step, enables an exceptionally high level of cleanliness.

Heated tank × vacuum drying

MEISTER achieves an unsurpassed drying performance by our unique heated cleaning tanks and the low boiling point drying system under vacuumed pressure environment. It is suited for components with deep holes, sintered components and parts with joints.

Rotary basket (Option)

Rotary basket allows for improvements in cleaning and drying performance by rotating the parts during the process. It is ideal for materials with overlapping , such as thin pressed parts.

Easy operation

The process is fully automated with excellent operability through the touch screen. The user-friendly interface allows you to easily control settings, create recipes, and manage operations.

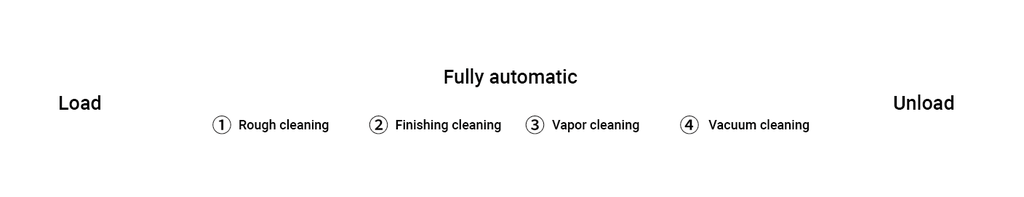

Cleaning process

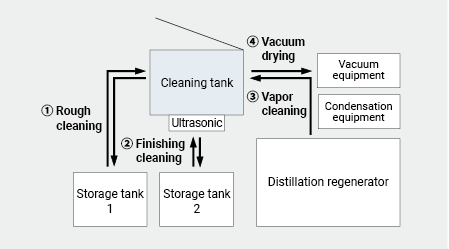

System configuration

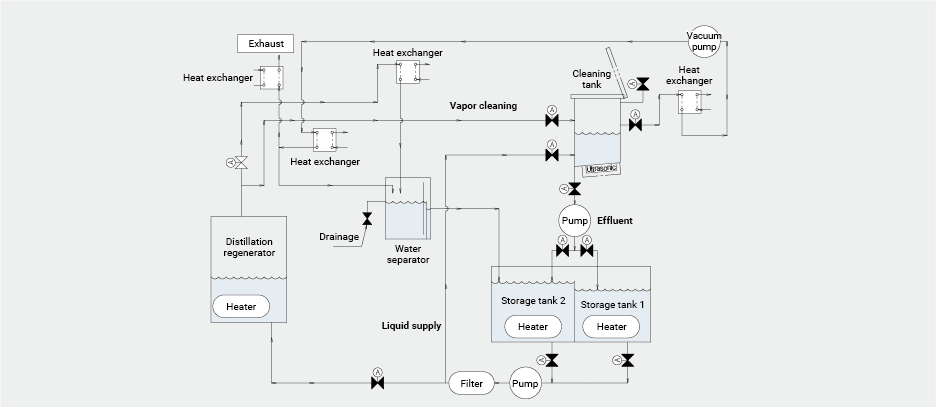

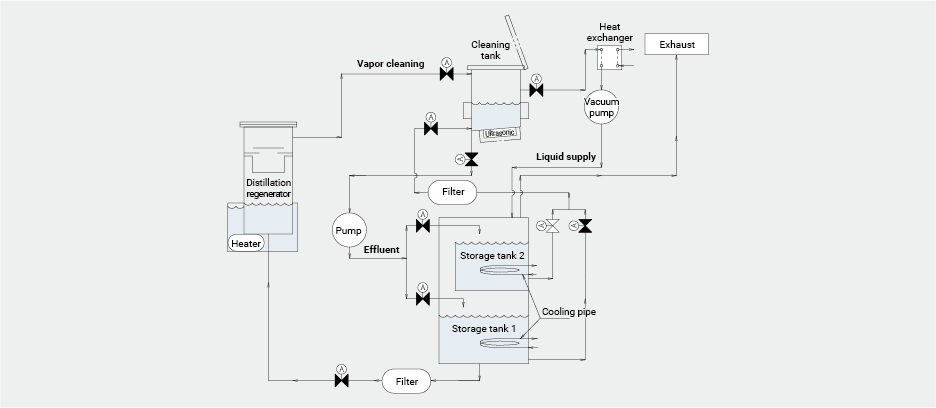

Once parts are loaded into the tank, the entire process operates automatically including the replacement of the cleaning solvent. After first and second step cleaning process is completed, parts are rinsed by the vapor process. The process is then moved to the vacuum drying process.

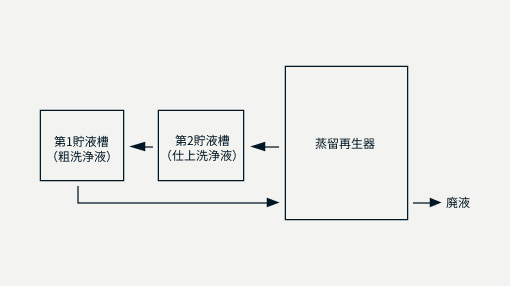

Solvent circulation system

Contaminants are removed and sent to the solvent regenerator. The regenerated solvent is supplied to tank 2. The solvent in the tank 2 is then supplied to tank 1 by the overflow. The concentrated contaminants in the distillation tank are regularly drained out.

Process flows

Customization

In addition to our standard process flows, we offer customization designs tailored for your specific needs. We provide solutions that suit your requirements, including a wide selection of conveyor systems such as in-line automation and advanced control systems.