SPRAY DRYER – TR

Rotate & Clean Up

Cleaning innovation you have never seen

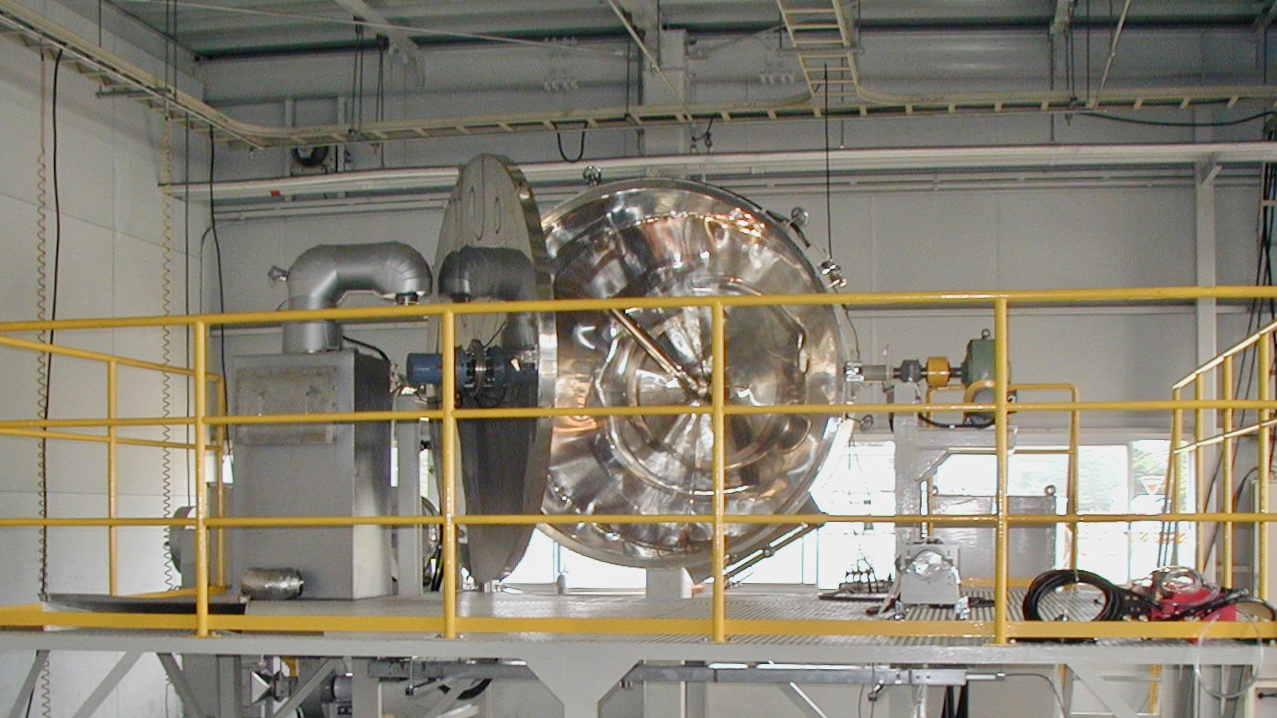

Easy cleaning

The chamber can be rotated 90 degrees to open the ceiling for easy cleaning. Manual or automatic rotation mechanism can be selected.

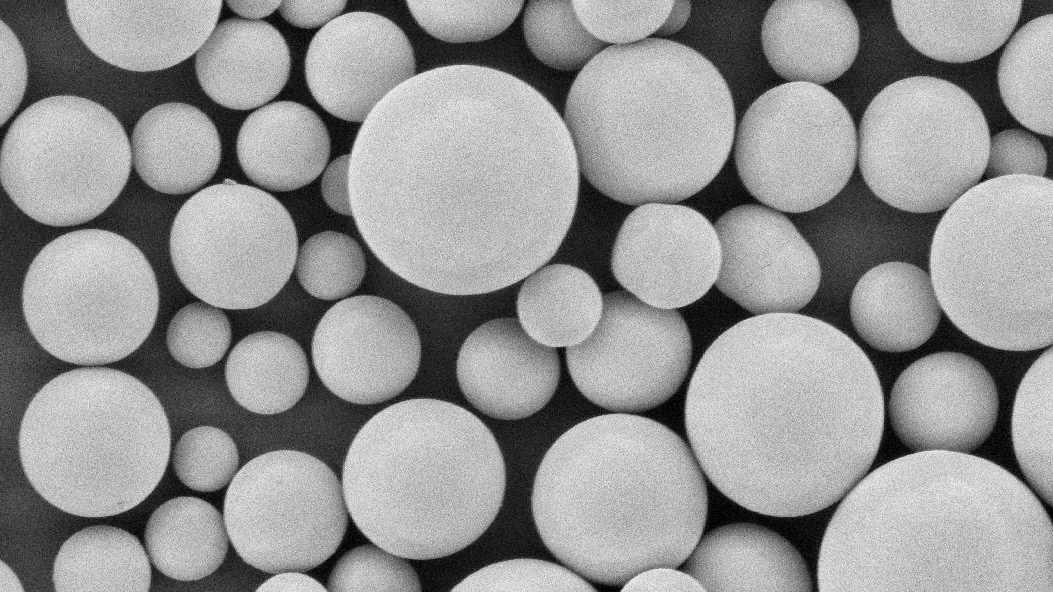

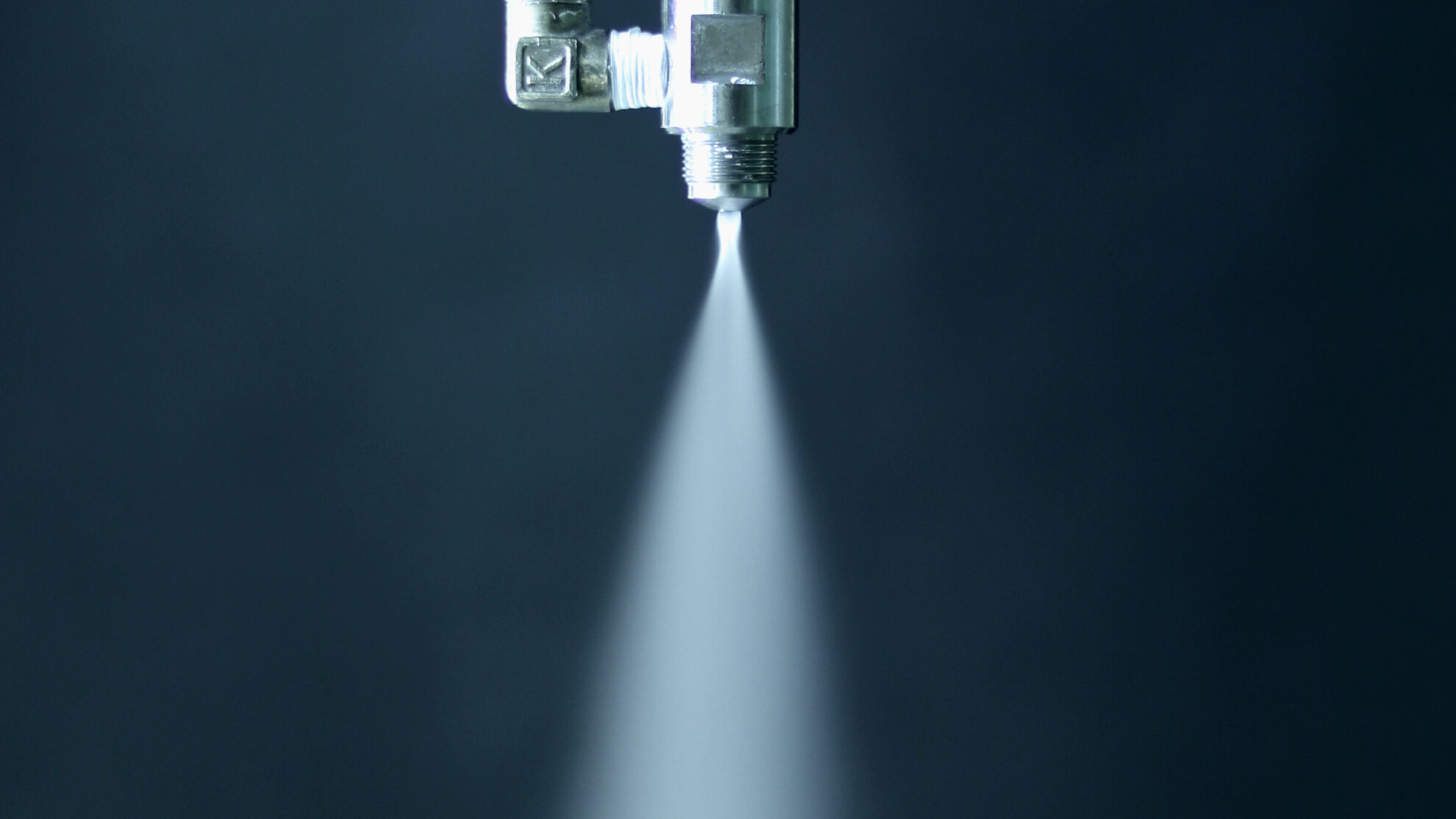

Atomization system

Rotary atomizers, Two-fluid nozzles, S-type two-fluid nozzles, Pressure nozzles, and Ultrasonic nozzles are available.

System selection

Open-cycle systems, Closed-cycle systems and Dual systems are available.

Operability & Visibility

Detailed design for safety and operability. Manholes and inspection windows are equipped to improve visibility and work efficiency.

Custom made

A wide variety of options are available including product and dust collection systems, heat sources, cleaning systems, and control systems.

Global network

We carry out projects globally by collaborating with our official engineering partners in each region under our quality management system.

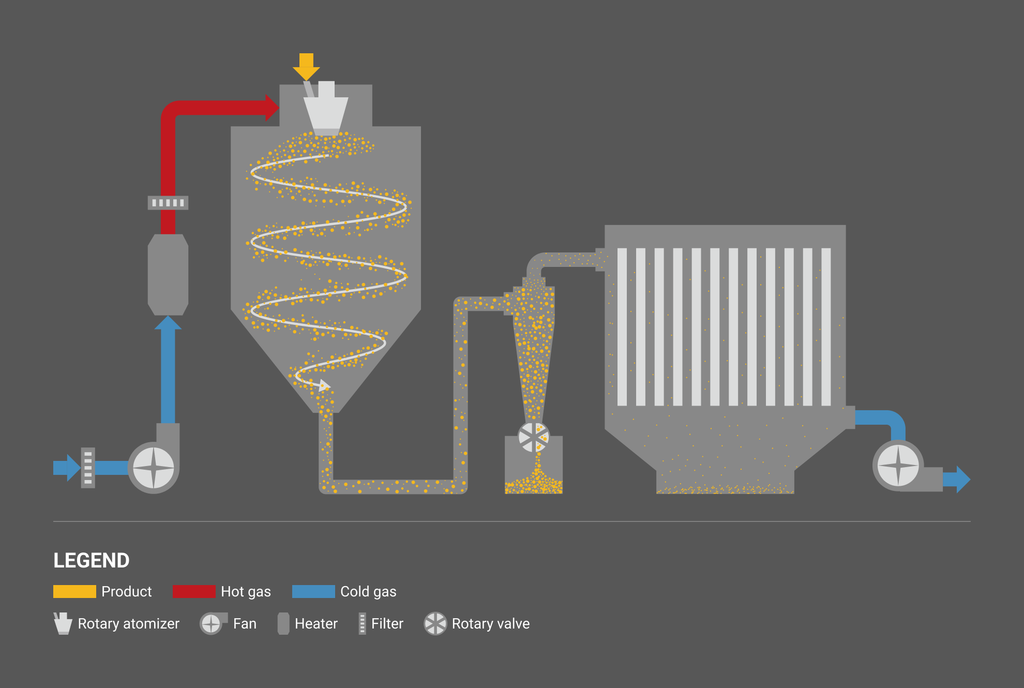

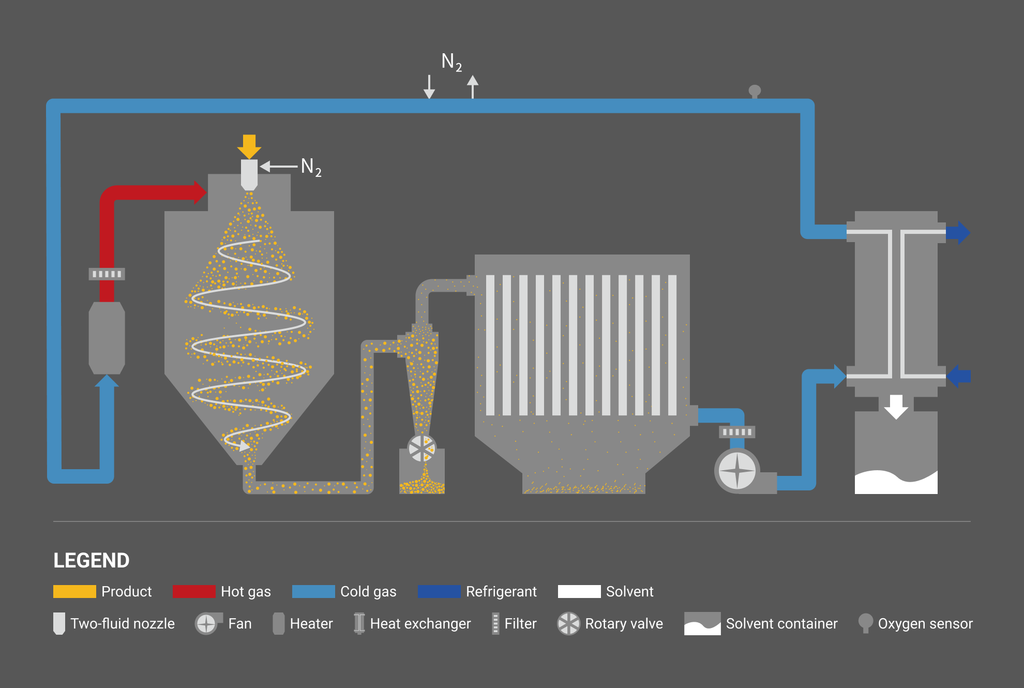

Process flows

Open-cycle system

Closed-cycle system

Specifications

| Model | TR80 | TR100 | TR120 | TR140 | TR160 | TR190 |

|---|---|---|---|---|---|---|

| Chamber diameter (mm) | φ800 | φ1000 | φ1200 | φ1400 | φ1600 | φ1900 |

| External dimensions W (mm) | 1900 | 1900 | 2300 | 2400 | 2500 | 5000 |

| External dimensions D (mm) | 3200 | 3400 | 3600 | 4100 | 4400 | 5700 |

| External dimensions H (mm) | 1800 | 2000 | 2200 | 2300 | 2500 | 3400 |

| Water evaporation capacity (kg/h) | 4 | 5 | 8 | 14 | 22 | 28 |

| Heater capacity (kW) | 6 | 8 | 10 | 18 | 28 | 35 |

* The approximate external dimensions include a heater, a cyclone and a bag filter unit.

* Heater capacity is calculated value based on inlet temperature at 230℃ and outlet temperature at 80℃.

* Water evaporation capacity is subject to change depending on inlet temp., outlet temp., process gas volume, and installation site conditions.