SPRAY DRYER – P

Small Footprint yet Big Capacity

Smart production with high efficiency & small footprint

High efficiency & Energy saving

Detailed design for high yield and low material loss. Energy can also be saved by exhaust heat circulation system.

Small footprint

A variety of our original technologies are available to save your footprint without compromising the capacity.

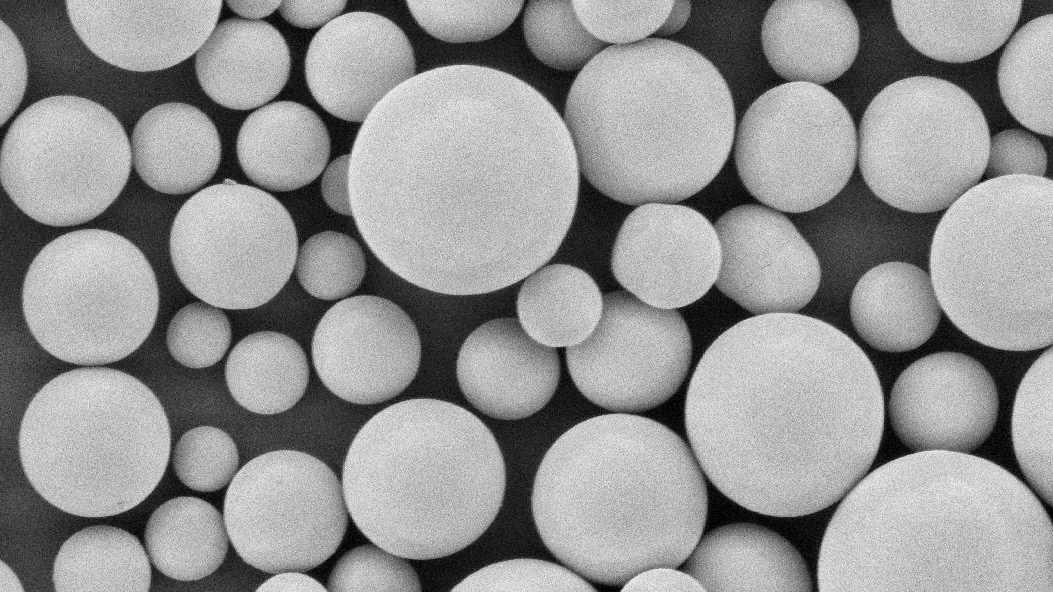

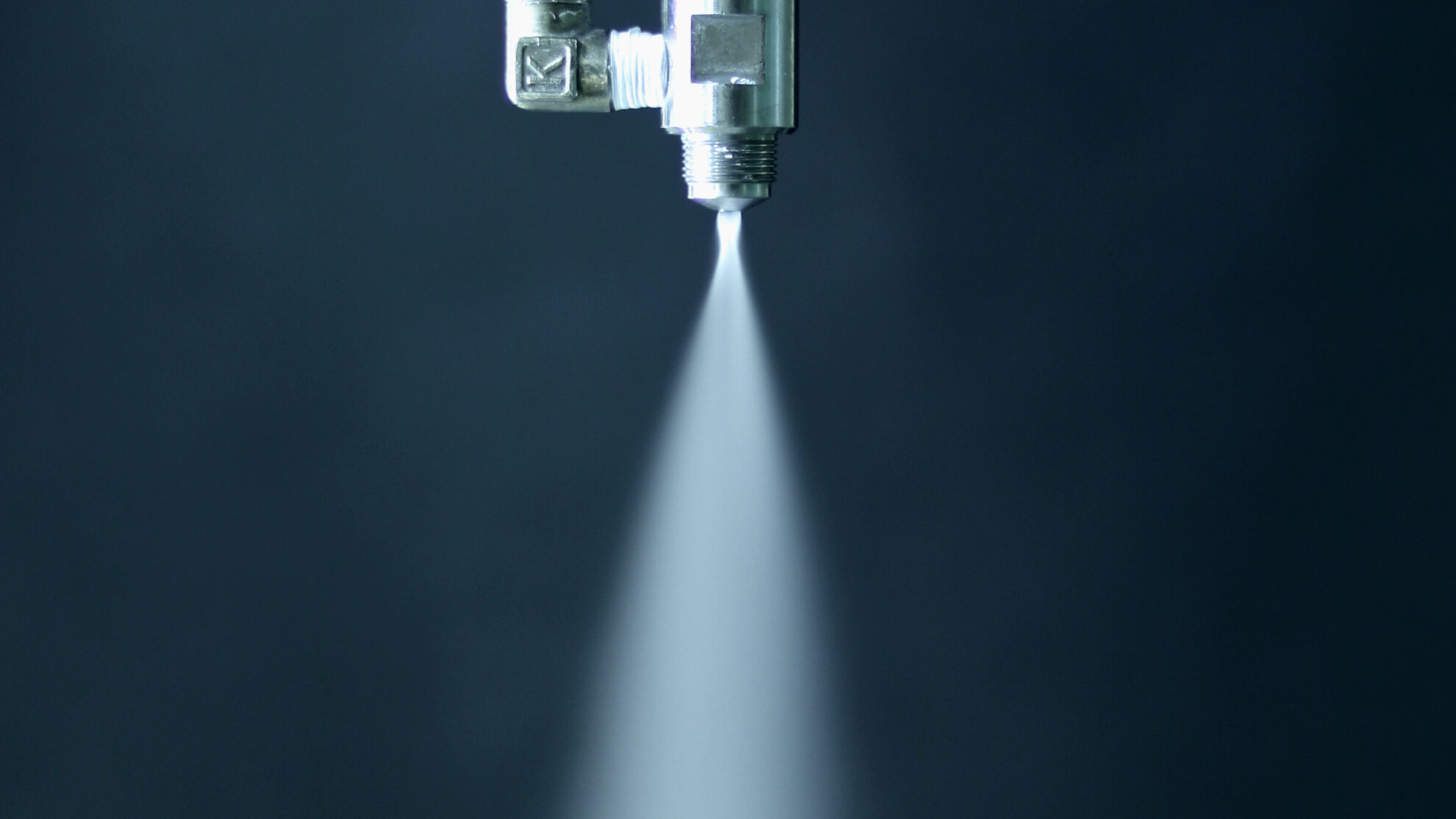

Atomization system

Rotary atomizers, Two-fluid nozzles, S-type two-fluid nozzles, Pressure nozzles, and Ultrasonic nozzles are available.

System selection

Open-cycle systems, Closed-cycle systems and Dual systems are available.

Flexible design

A wide variety of options are available including powder collection, heat sources, cleaning systems, and controls.

Global network

We carry out projects globally by collaborating with our official engineering partners in each region under our quality management system.

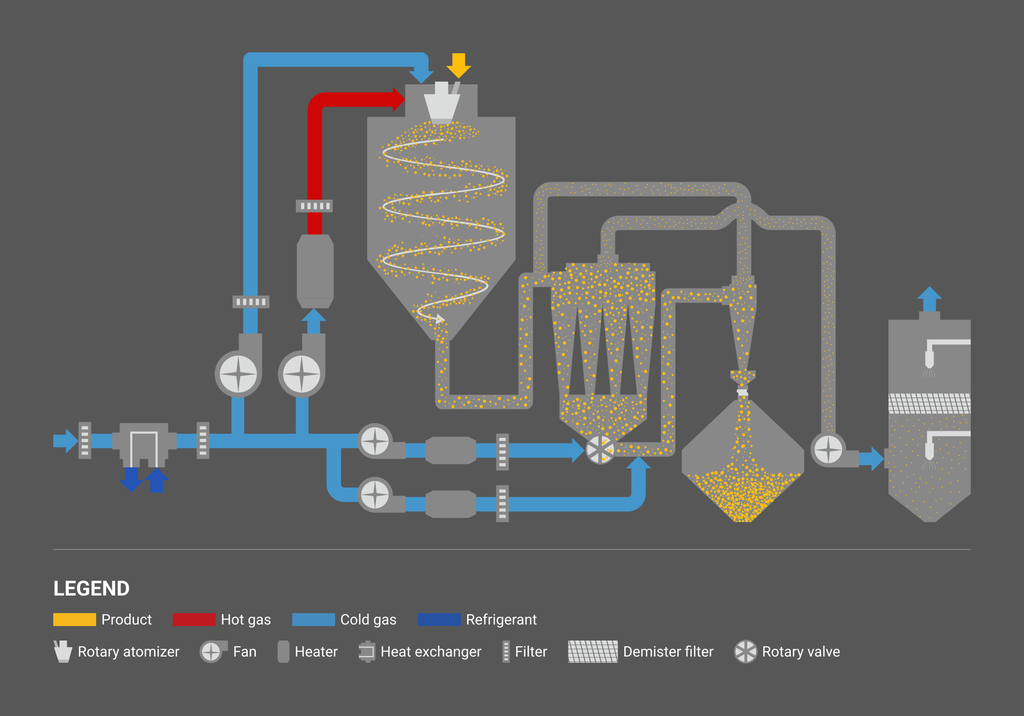

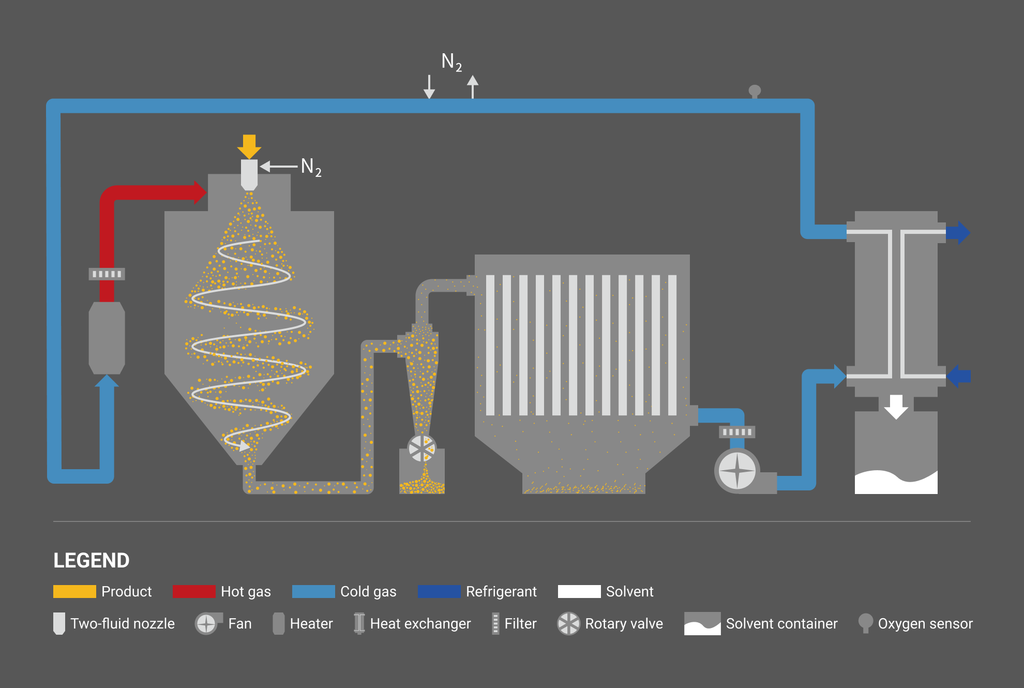

Process flows

Open-cycle system

Closed-cycle system

製品仕様

| Model | P220 | P240 | P260 | P290 | P300 |

|---|---|---|---|---|---|

| Chamber diameter (mm) | φ2200 | φ2400 | φ2600 | φ2900 | φ3000 |

| External dimensions W (mm) | 3700 | 3900 | 4200 | 4500 | 4600 |

| External dimensions D (mm) | 3900 | 4400 | 4900 | 6300 | 6500 |

| External dimensions H (mm) | 3900 | 4400 | 4900 | 5500 | 5700 |

| Water evaporation capacity (kg/h) | 32 | 40 | 48 | 53 | 60 |

| Heater capacity (kW) | 40 | 50 | 60 | 68 | 80 |

* The approximate external dimensions include a heater, a cyclone and a bag filter unit.

* Heater capacity is calculated value based on inlet temperature at 230℃ and outlet temperature at 80℃.

* Water evaporation capacity is subject to change depending on inlet temp., outlet temp., process gas volume, and installation site conditions.