FREEZE GRANULATOR – CS30

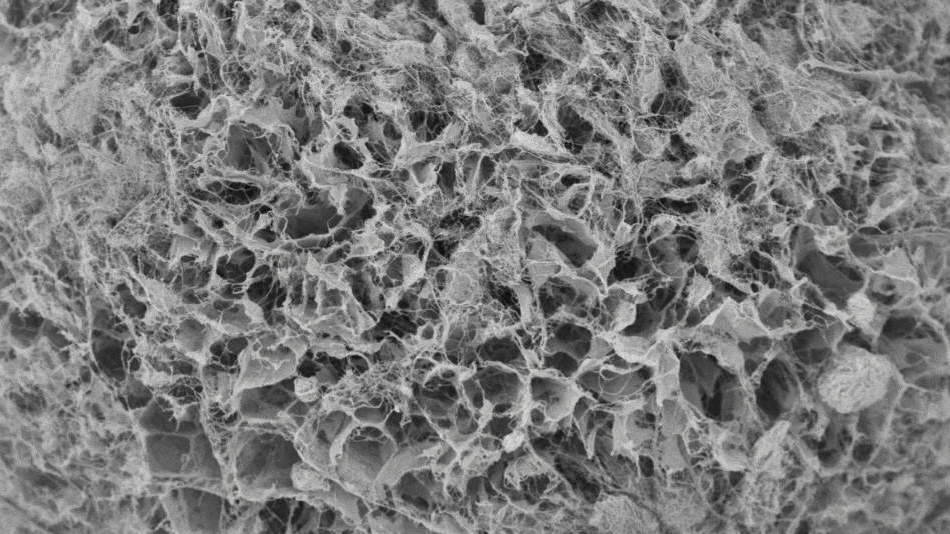

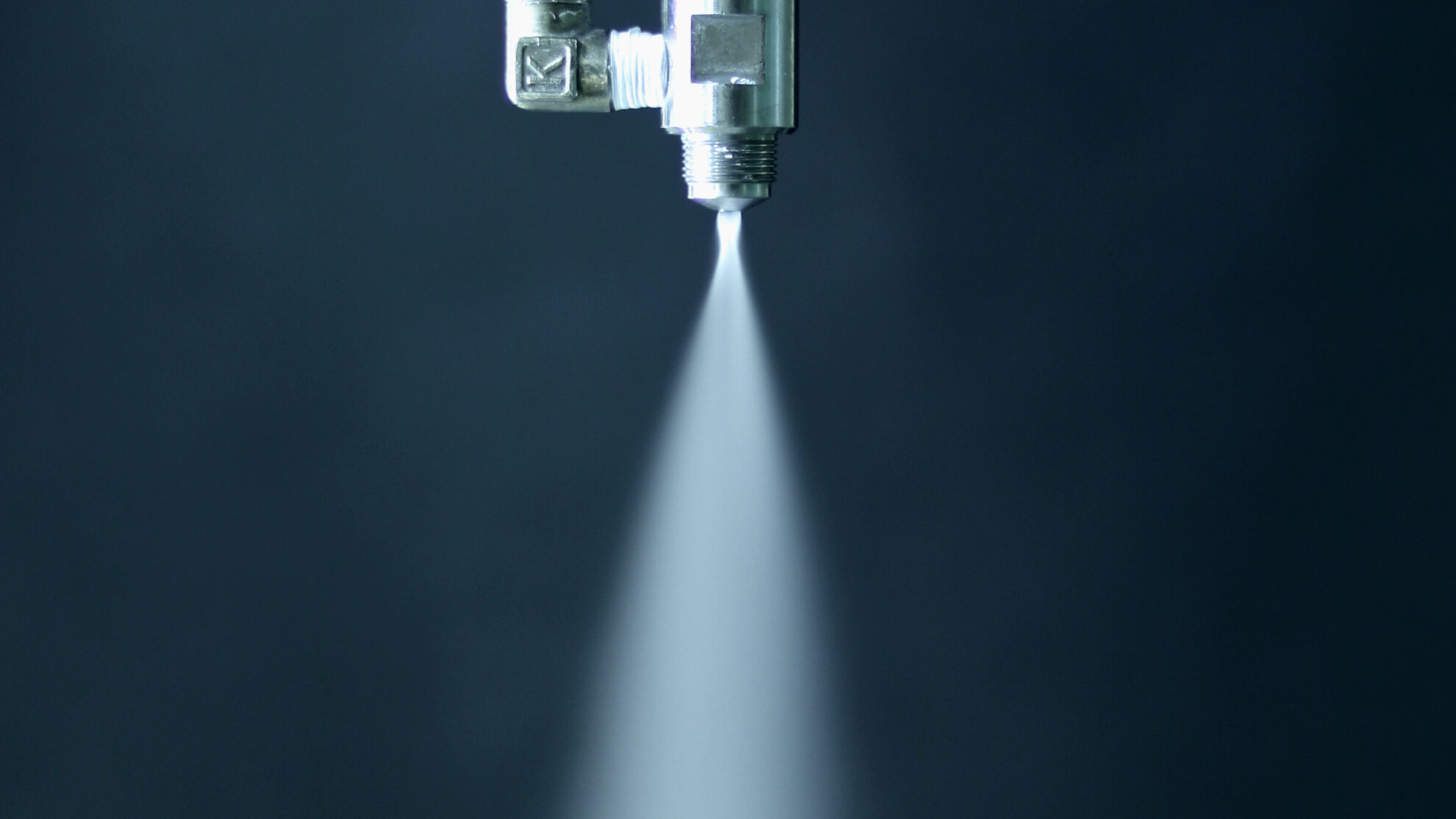

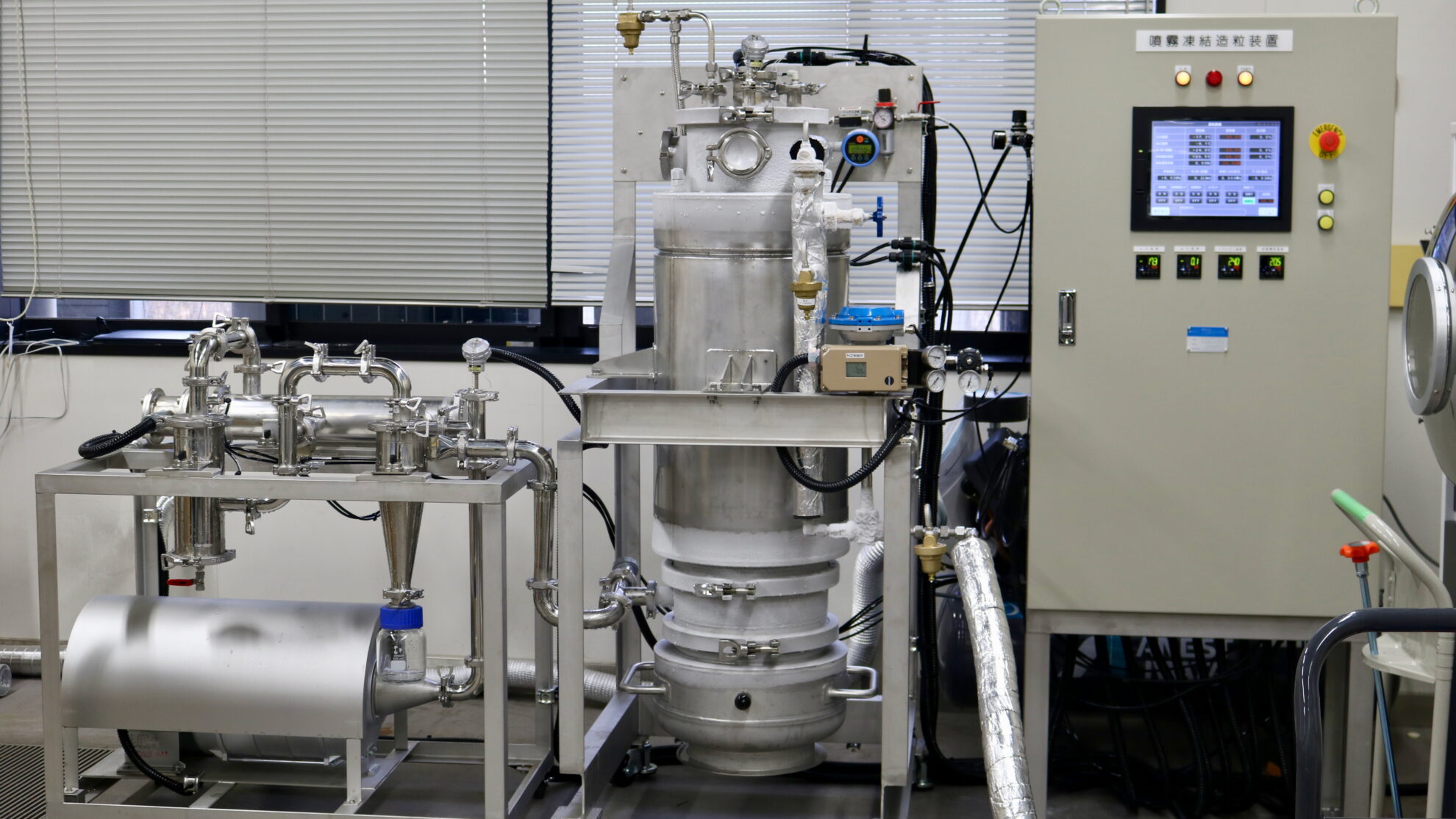

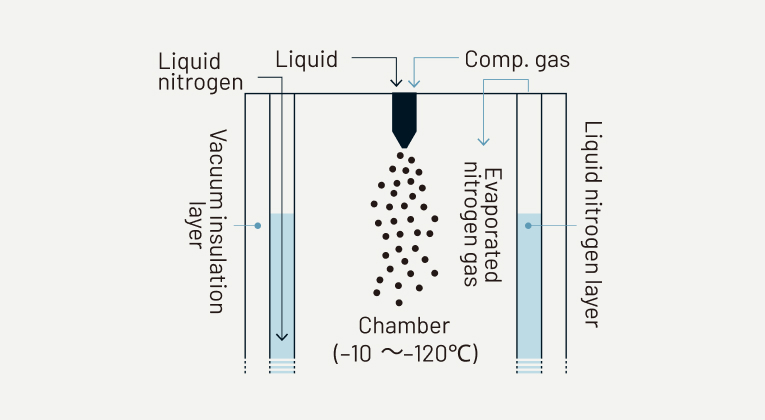

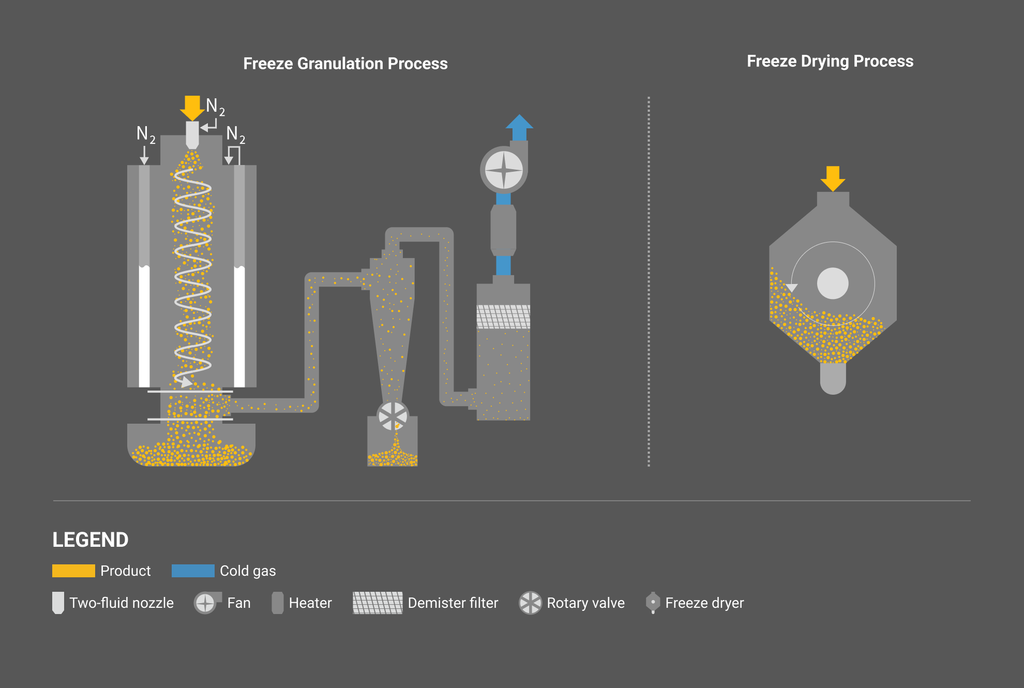

CS30 is the world’s first production scale freeze granulator that uses patented technology to enable continuous production. Liquid nitrogen is supplied to the outer layer of the jacketed chamber to control the process temperature. The evaporated nitrogen gas in the outer layer is supplied to the inner layer of the chamber. A liquid mateial is atomized into the inner layer by a two-fluid nozzle and droplets get frozen by contacting with the nitrogen gas. Process temperature can be controlled by adjusting the supply amount of liquid nitrogen. Frozen granules are collected in the container installed at the bottom of the chamber. The collected frozen granules are freeze-dried using freeze dryer TFD-10 or RHEOFREED. By connecting multiple freeze dryers to CS30 and automatically switching connections, it is possible to process as semi-continuous production.

Process flow

Specifications

| Model | CS30 |

| Chamber diameter | φ300mm |

| Atomization system | Two-fluid nozzles, S-type two-fluid nozzles |

| Material feed capacity | Up to 15kg/h |

| Cooling temperature | −10 ~ −120℃ |

| Cooling system | Dry cooling system by evaporated nitrogen gas |