Double-tank fluorinated solvent cleaning system offers strong particle removal performance using fluorinated solvents. The system achieves powerful cleaning and drying properties over two processes: Ultrasonic immersion cleaning in tank 1 and vapor cleaning in tank 2. We also offer scaled-up options for large-scale processes.

Specifications

| Jig dimensions | 150W×150D×100H(mm) | Heater (tank 2) | 700W |

| Ultrasonic device | 200W/40kHz | Power supply | 3 phase 200V/220V |

| External dimensions | 1000W×600D×900H(mm) | Coolant utility | 10L /min |

| Heater (tank 1) | 700W | Solvent volume | 17L |

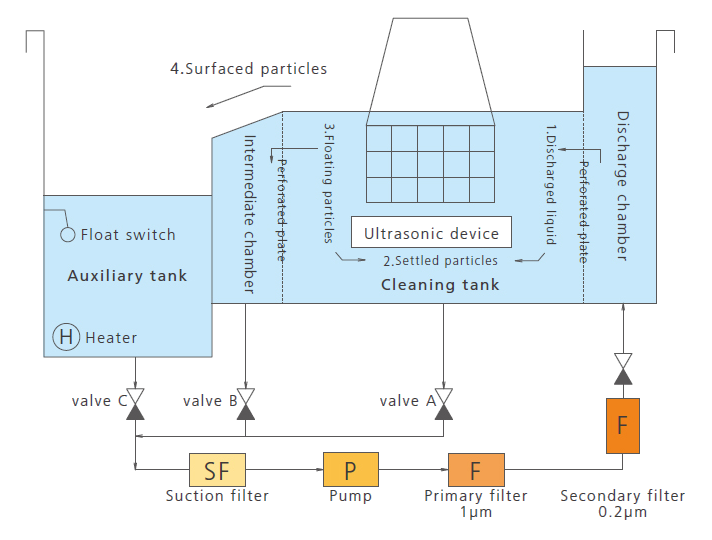

Filtration system for cleaning tanks employing a perforated plate

The perforated plates are fitted to the cleaning tank, and the level of cleanliness inside the tank is improved by discharging or collecting the cleaning solvent. Cleaning solvent that passes through the suction filter is pumped through filters and sent from the discharge chamber to the inside of the tank (1). Settled particles are expelled from the bottom of the tank (2), and floating particles are expelled from the perforated plate to the intermediate chamber (3). Surfaced particles are expelled to the auxiliary tank through overflow (4). This enables efficient purification that is not influenced by the relative gravity of the particles or solvent flow. The expulsion balance for (1) to (4) is adjustable by valve A, B and C.

Send an inquiry by contact form

PRECI takes your privacy seriously. All information you provide shall be held in strict accordance with our Privacy Policy.

* are required fields.