MEISTER α

For hydrocarbon or silicone solvents, etc. (explosion proof)

MEISTER β

Fluorinated, brominated, or chlorinated solvents, etc.

MEISTER Ω

Non-halogenated non-flammable solvent, etc. (explosion proof)

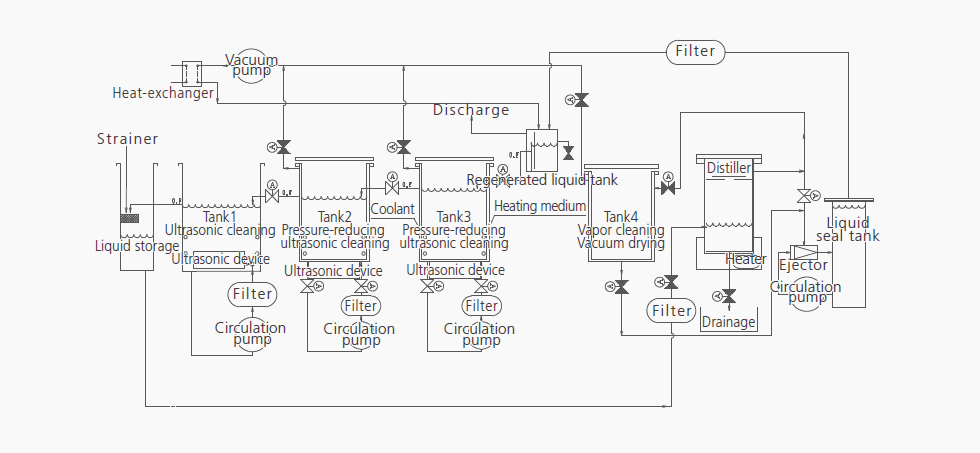

Pressure-reducing ultrasonic cleaning×Double immersion cleaning×Vapor cleaning

With our unique pressure-reducing ultrasonic cleaning technology, we not only achieve outstanding cleaning performance, but also a reduction of solvent consumption volume. The automatic process features our unique “double immersion cleaning” system ‒ the first step with a rough cleaning, and the second with a finish cleaning. The solvent is replaced automatically at each step. The vapor cleaning/rinsing process, as the third step, allows for an exceptionally high level of cleanliness.

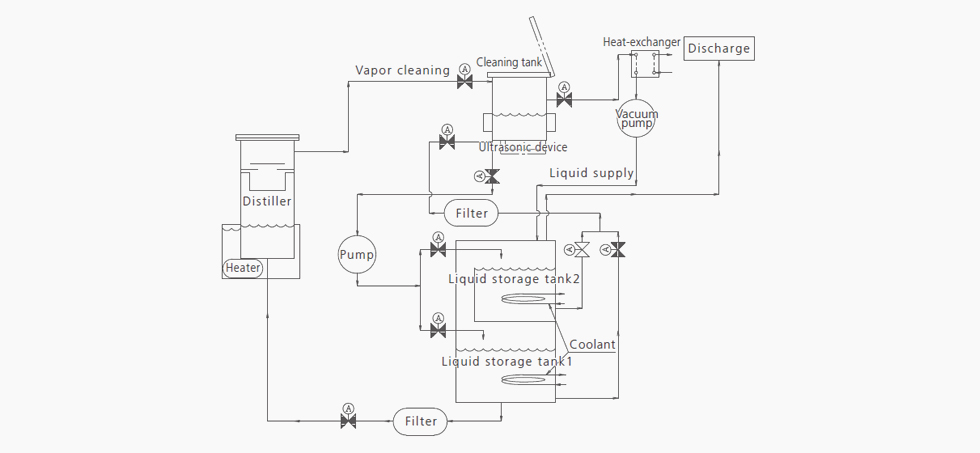

Double immersion cleaning×Vapor cleaning

In addition to low boiling point drying by reducing pressure levels, MEISTER achieves an unsurpassed drying performance by heating the cleaning tank itself. It is suited for components with deep holes, sintered components and parts with joints.

Rotating basket (Type B)

The rotating basket allows for further improvements in cleaning and drying performance by rotating the component in the cleaning process. It is ideal for materials with deep drawing parts and overlapping materials, such as thin pressed parts.

Comprehensive management through easy operation

The process is fully automated with excellent operability through the touch screen. The user-friendly interface allows you to control settings, create recipes, and manage operations with ease.

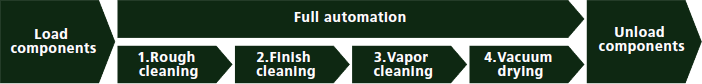

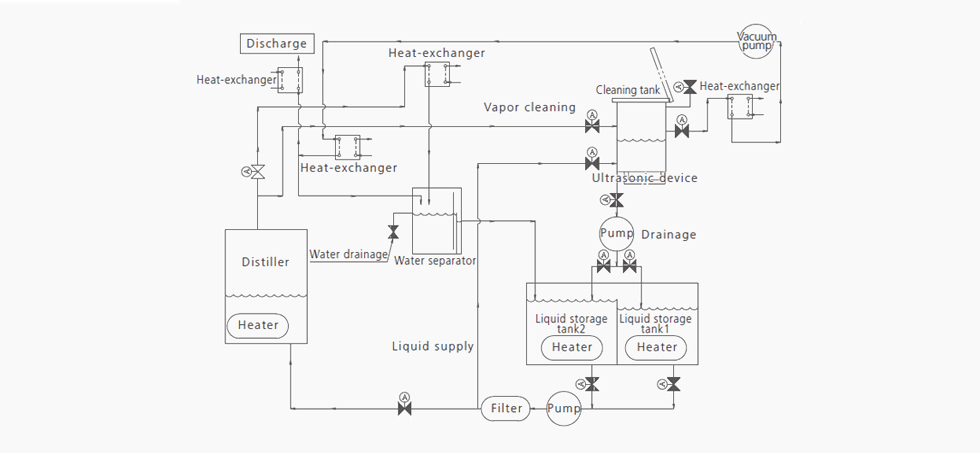

Cleaning process

Basic system flow

Once the components are loaded into the tank, the entire process is operated automatically, including the replacement of the cleaning solvent. After rough and finish cleaning is completed, the components are rinsed by vapor. The components are then moved onto the vacuum drying process.

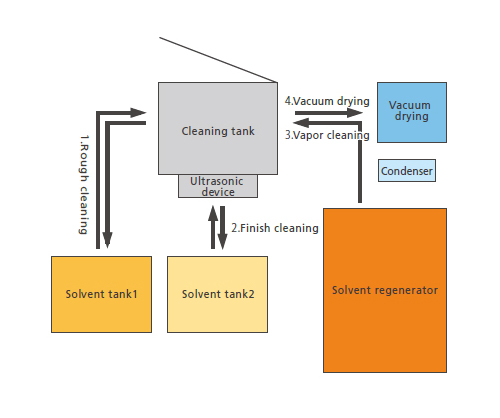

Solvent circulation system

Contaminants are removed from inside the cleaning tank and are separated and dissolved. Then, they are sent to the liquid storage tank together with the used solvent. The contaminants inside the first liquid storage tank are sent to the distillation tank. The used solvent is distilled separately into waste contaminants and the solvent itself. The solvent regenerated in the distillation tank is supplied to the second liquid storage tank. The first liquid storage tank is supplied from the overflow of the second liquid storage tank. The concentrated contaminants in the distillation tank are regularly drained out.

Process flow examples

Customized design

In addition to the basic system flow, we offer further customization designs tailored for your specific needs. We provide solutions that suit your requirements, including a wide selection of conveyor systems such as in-line automation systems, and advanced control systems. In addition, carry-in route, installation spaces, and other delivery-related requirements can also be flexibly designed.

Send an inquiry by contact form

PRECI takes your privacy seriously. All information you provide shall be held in strict accordance with our Privacy Policy.

* are required fields.