Multi-stage hot air circulation vaporizer

The multi-stage hot air circulation vaporizer is attached or built-in to the cleaning system. Drainage from the cleaning system can be greatly reduced through vaporizing and condensing. If aqueous systems are equipped with one of these, the cleaning chemistry can be recycled when it is moved on to the next tank, meaning a reduction of chemistry filling. Rinsing performance is improved because water can be supplied to the rinsing tank continuously.

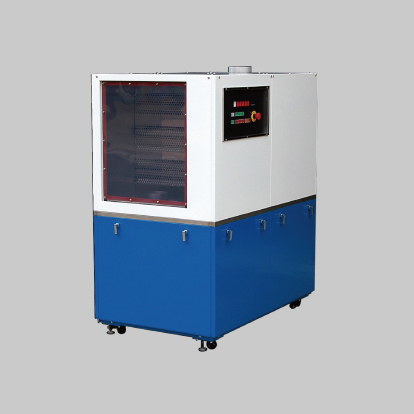

Vacuum & hot air dual drying system

The vacuum & hot air dual drying system is a hybrid drying system that is equipped with both vacuum drying and hot air drying functions. The vacuum dryer compensates for problematic situations of hot air dryer, such as poor drying of sac holes, while the hot air dryer helps heighten the heat of products. Automatic alternate operation between hot air dryer and vacuum dryer achieves an excellent drying performance. The alternate operation cycle length can be set to suit the requirement. The hot air circulation process has an internal HEPA filter, and can remove particles.

Specifications

| External dimensions | 1400W×950D×1000H(mm) | Power of chamber insulation heater | 0.7kW×2 |

| Internal dimensions of drying chamber | 410W×410D×420H(mm) | Ultimate vacuum pressure | 102Pa |

| Power of vacuum pump | 1.1kW | Power supply | 3 phase 200V/220V |

| Power of electric heater | 10kW | Compressed air utility | 0.4MPa or more |

| Power of fan | 0.4kW |

Suction dryer

The suction dryer is a dryer that dehydrates and dries the product after an aqueous cleaning process while still in the cleaning basket. The moisture is drawn off by a jet air current from the lower part of the drying chamber, enabling powerful dehydration. Hot air is supplied from the upper part of the drying chamber. As well as the standard square basket, a rotating barrel can also be used.

Specifications

| External dimensions | 1000W×1325D×1000H(mm) | Power of high-pressure fan | 1.5kW/2.2kW(Selectable) |

| Compatible basket dimensions | 250W×350D×200(+handle 130)H(mm) | Power of electric heater | 10kW |

| Compatible rotating barrel dimensions | Opposite side 160×250L(mm) |

Hydrocarbon solvent distillation & regeneration system

The hydrocarbon solvent distillation and regeneration system allows for a highly efficient hydrocarbon solvent recycling process with pressure reducing technology that enables safe operations of flammable solvents. The system is compact in size and can be equipped with existing cleaning processes, without the concern for finding space.

Specifications

| External dimensions | 800W×700D×1400H(mm) | Cleaning solvents | Hydrocarbon solvents |

| Distillation capacity | Max. 20L /h | Power supply | 3 phase 200V/220V |

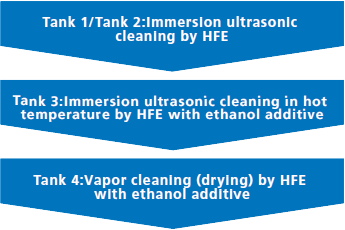

Four-tank fluorinated solvent de-liquoring & drying system

The four-tank fluorinated solvent de-liquoring and drying system is ideal for replacement of an IPA substitution and drying process. Our system offers simplified fluid control and improved finishing cleanliness through the use of two types of fluorinated solvents. This system reduces heat damage to products by drying at a low boiling point. Additionally, the system prevents spots through an initial removal of moisture. HFC and HFE are also available.

System flow

Send an inquiry by contact form

PRECI takes your privacy seriously. All information you provide shall be held in strict accordance with our Privacy Policy.

* are required fields.